CH_4

advertisement

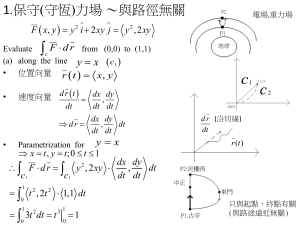

CH-4 Plane problems in linear isotropic elasticity HUMBERT Laurent laurent.humbert@epfl.ch laurent.humbert@ecp.fr Thursday, march 18th 2010 Thursday, march 25th 2010 1 4.1 Introduction Framework : linear isotropic elasticity, small strains assumptions, 2D problems (plane strain , plane stress) The basic equations of elasticity (appendix I) : - Equilibrium equations (3 scalar equations) : div σ f 0 ij , j fi 0 Explicitly, f : body forces (given) : Cauchy (second order) stress tensor xx yx zx fx 0 x y z yx yy yz fy 0 x y z zx zy zz fz 0 x y z e3 R3 x, x1 e1 σT σ ij ji z, x3 symmetric e2 y, x2 Cartesian basis 2 - Linearized Strain-displacement relations (6 scalar equations) : ε 1 T u u 2 1 ui u j ij 2 x j xi Equations of compatibility: 2 11 2 22 2 12 2 2 2 x2 x1 x1 x 2 23 13 12 2 11 , x1 x1 x 2 x 3 x 2 x 3 2 23 2 22 2 33 2 2 2 x3 x2 x 2 x 3 , 23 13 12 2 22 x 2 x1 x 2 x 3 x 3 x1 , 23 13 12 2 33 x 3 x1 x 2 x 3 x1 x 2 2 33 2 11 2 12 2 2 2 x1 x3 x 3 x1 because the deformations are defined as partial derivative of the displacements u1 , u 2 , u 3 - Hooke’s law (6 scalar equations) : Isotropic homogeneous stress-strain relation , σ tr εI 2 ε ij kk ij 2 ij Inversely, 1 ε tr σ I σ E E 1 ij kk ij ij E E 15 unknowns ui , E Lamé’s constants 3 2 with E 0 2 1 1 2 ij , ij → well-posed problem → find u 4 Young’s modulus for various materials : 5 1D interpretation : 1 Before elongation 3 2 traction 33 E 33 11 22 33 0 0 0 σ 0 0 0 0 0 33 but 0 0 33 E 33 E 0 ε 0 0 33 E 0 6 - Navier’s equations: (λ+μ)u k,ki +μui,jj +fi =0 3 displacement components ui taken as unknowns - Stress compatibility equations of Beltrami - Michell : ij,kk 1 mm,ij fi, j f j,i f n,n ij 0 1 1 6 stress components ij considered as unknowns 7 Boundary conditions : Displacements imposed on Su uu t o t Surface tractions applied on St t σn t n outwards unit normal to St f u St Su St Su → displacement and/or traction boundary conditions to solve the previous field equations 8 4.2 Conditions of plane strain Assume that u 3 0 Strain components : 11 u1 x1 22 u2 x2 1 u1 u 2 12 2 x 2 x1 Thus, 11 12 0 ε 21 22 0 0 0 0 “thick plate” functions of x1 and x2 only 9 Associated stress components 11 E 11 1- ν ν 22 1 ν 1- 2ν E 22 1- ν ν11 22 1 ν 1- 2ν 12 11 12 0 σ 21 22 0 0 0 33 E νE 21 and also (!), 33 11 22 1 ν 1 ν 1- 2ν Inverse relations, 1 ν 1 ν 11 ν 22 E 1 ν 1 ν 22 ν 11 22 E 11 12 1 ν 12 E rewritten as 1 11 11 ν *22 E* 1 22 22 ν *11 E* E* E , * 1 ν2 1 ν 10 - 2D static equilibrium equations : n t 11 12 f1 0 x1 x 2 12 22 f2 0 x1 x 2 f x1 ,x2 : body forces Surface forces t are also functions of x1 and x2 only t1 11 n1 12 n 2 t 2 12 n1 22 n 2 n1 , n 2 : components of the unit outwards vector n 11 - Non-zero equation of compatibility (under plane strain assumption) 2 11 2 22 2 12 2 2 2 x2 x1 x1 x 2 implies for the relationship for the stresses: 2 2 1 f1 f 2 2 2 11 22 1 ν x1 x 2 x1 x 2 That reduces to by neglecting the body forces, 2 2 2 2 11 22 0 x1 x 2 Proof ? 12 Proof: - Introduce the previous strain expressions in the compatibility equation 11 1 ν 1 ν 11 ν 22 E 22 12 1 ν 12 E 1 ν 1 ν 22 ν 11 E one obtains 212 2 2 1 ν 11 ν 22 1 ν 22 ν 11 2 x 22 x12 x1 x 2 (1) - Differentiate the equilibrium equation and add 11 12 f1 0 x1 x1 x 2 12 22 f2 0 x 2 x1 x 2 211 222 2 12 2 2 x1 x 2 x x 22 1 - Introduce (2) in (1) and simplify f1 f 2 x 1 x2 (2) 13 4.3 Conditions of plane stress Condition : 33 13 23 0 thin plate From Hooke’s law, 1 11 ν 22 E 1 22 22 ν 11 E 11 12 1 ν 12 E Similar equations obtained in plane strain : E* E * and also, ν 33 11 22 , 13 23 0 E functions of x1 and x2 only 14 Inverse relations, 11 E ν 22 2 11 1 ν 22 E ν11 2 22 1 ν E 12 21 1 ν 11 12 0 σ 21 22 0 0 0 0 and the normal out of plane strain , 33 ν 11 22 1 ν 15 Airy’s stress function : introduce the function as 2 11 x 2 2 2 22 x12 then substitute in 2 12 x1 x 2 equations of equilibrium automatically satisfied ! 2 2 2 2 11 22 0 x1 x 2 4 4 4 2 2 0 leads to 4 2 4 x1 x1 x 2 x 2 4 0 Biharmonic equation Same differential equation for plane stress and plane strain problems Find Airy’s function that satisfies the boundary conditions of the elastic problem 16 4.4 Local stress field in a cracked plate : - Solution 2D derived by Williams (1957) - Based on the Airy’s stress function Notch / crack tip r , : polar coordinate system Crack when , notch otherwise 17 Local boundary conditions : θθ rθ 0 for α, r0 Remote boundary conditions Find σ r, or σ x1 ,x2 stress field u r, or displacement field u x1 ,x2 Concept of self-similarity of the stress field (appendix II) : Stress field remains similar to itself when a change in the intensity (and scale) is imposed Stress function in the form r,θ r λ θ , 0 18 Biharmonic equation in cylindrical coordinates: 2 1 1 2 2 d 2 2 0 r 2 r r r 2 2 d2 r 2 d 4 d 2 2 4 2 2 2 2 2 0 (1) d d a Consider the form of solution e , a cst 1 m2 λ 2 2 λ2 m λ2 λ 2 0 2 with m a 2 Solutions of the quadratic equation : m1 2 a1,2 2 i m2 ( 2 )2 a3,4 2 i 2 complex conjugate roots 2 19 Consequently, : c1 ei c2 ei c3 e 2 i c4 e 2 i ci (complex) constants Using Euler’s formula ei cos i sin A cos Bsin Ccos 2 Dsin 2 A, B, C and D constants to be determined … according to the symmetry properties of the problem ! 20 Modes of fracture : A crack may be subjected to three modes More dangerous ! Notch, crack Example : Compact Tension (CT) specimen : F F natural crack Mode I loading F F 21 Mode I – loading r s with s A cos Ccos 2 symmetric part of Stress components in cylindrical coordinates 1 1 2 r r 2 r r r 2 2 2 r 1 1 2 r 2 r r r Use of boundary conditions, r, r r, 0 s 0 0 ds 0 d 0 A cos C cos 2 A sin C 2 sin 2 0 22 Non trivial solution exits for A, C if cos sin cos 2 0 2 sin 2 2 cos sin 2 cos 2 sin 0 or tan 2 sin 2 2 cos 2 … that determines the unknowns For a crack, it only remains sin 2 0 n 2 n integer infinite number of solutions 23 Relationship between A and C For each value of n → relationship between the coefficients A and C → infinite number of coefficients that are written: An , Cn n ..., 2, 1, 0, 1, 2, ... From, A sin C 2 sin 2 0 with n 2 A n n sin n Cn 2 2 (crack) n 2 sin n 2 0 2 2 n sin n A n C n 2 2 n 2 0 2 0 or 1 A n C n 4n n 24 Airy’s function for the (mode I) problem expressed by: r n n 2 n n A n cos 2 Cn cos 2 2 Reporting Cn A n n 4n nθ n n (r,θ) A n r n 2 cos cos 2 θ 2 n4 2 n 25 Expressions of the stress components in series form (eqs 4.32): Starting with, nθ n n (r,θ) A n r n 2 cos cos 2 θ 2 n4 2 n 1 1 2 and recalling that, r r r r r 2 2 n n nθ n n A n r 2 sin sin 2 θ 2 2 2 n 2 n 2 1 2 nθ n n 4 n 2 n 2 A r cos cos 2 n n θ r 2 2 2 2 2 2 2 1 nθ n n n A n r 2n 2 cos cos 2 θ r r 2 n4 2 2 n 2 n n nθ n n n n (2 n 2) rr A n r 2 cos 2 θ 1 cos 2 n 4 2 2 2 n 2 2 26 2 From, 2 r θθ A n n n n (2 n 2) nθ n n 1 r cos cos 2 θ 2 2 2 n4 2 1 1 2 and using, r 2 r r r 1 nθ n n 2 n 2 n A r sin sin 2 n θ 2 r 2 2 2 2 n 2 nθ n n n n A n r 1n 2 sin sin 2 θ r n 2 2 2 2 2 1 2 nθ n n n n A n r 2n 2 sin sin 2 θ r r n 2 2 2 2 2 n n nθ n n n r A n r (2 n 2) 1 sin 1 sin 2 θ 2 2 2 2 n 2 2 27 Range of n for the physical problem ? The elastic energy at the crack tip has to be bounded Wd rdr d ij ij but, ij r (2 n 2) ... ij r (2 n 2) ... Wd (4 n) r ... r dr d is integrable if 3 n 0 n 3 or 5 3 ... , 3, , 2 , 2 2 28 Singular term when n 3 or 3A 3 5cos cos 2 2 4 r 3A 3 3cos cos 2 2 4 r 3 2 rr r 3A 4 r 3A K I 2π 3 sin sin 2 2 Mode - I stress intensity factor (SIF) : K I rr KI KI f rr 2r 2r 1 3 5 cos cos 4 2 4 2 KI KI f 2r 2r 1 3 3 cos cos 4 2 4 2 r KI KI 1 1 3 f r sin sin 2 4 2 2r 2r 4 29 In Cartesian components, KI 3 xx cos 1 sin sin 2 2 2 2 r KI 3 yy cos 1 sin sin 2 2 2 2 r KI 3 xy cos sin cos 2 2 2 2 r → does not contain the elastic constants of the material → applicable for both plane stress and plane strain problems : zz 0 xx yy plane stress plane strain , xz yz 0 is Poisson’s ratio 30 Asymptotic Stress field: r y rr yy xy y xx r θ O x r θ Similarly, rr , , r O x xx , yy , xy n KI ij fij An r 2 gij( n ) 2r n 0 1 singularity at the crack tip + higher–order terms (depending on geometry) r fij : dimensionless function of in the leading term An amplitude , gij dimensionless function of for the nth term 31 Evolution of the stress normal to the crack plane in mode I : yy KI cos 2 2 r 3 1 sin sin 2 2 Stresses near the crack tip increase in proportion to KI If KI is known all components of stress, strain and displacement are determined as functions of r and (one-parameter field) 32 Singularity dominated zone : → Admit the existence of a plastic zone small compared to the length of the crack 33 Expressions for the SIF : Closed form solutions for the SIF obtained by expressing the biharmonic function in terms of analytical functions of the complex variable z=x+iy Westergaard (1939) Muskhelishvili (1953), ... Ex : Through-thickness crack in an infinite plate loaded in mode -I: K I a Units of stress length MPa m or MN m3 / 2 34 For more complex situations the SIF can be estimated by experiments or numerical analysis K I Y a Y: dimensionless function taking into account of geometry (effect of finite size) , crack shape → Stress intensity solutions gathered in handbooks : Tada H., Paris P.C. and Irwin G.R., « The Stress Analysis of Cracks Handbook », 2nd Ed., Paris Productions, St. Louis, 1985 → Obtained usually from finite-element analysis or other numerical methods 35 Examples for common Test Specimens KI P a Y B W W B : specimen thickness a Y W a lim Y a W 0 W a 2W a cos 2W 2 tan a 0.752 2.02 W a 1 . 12 W 3 a 0.37 1 sin 2 W K I 1.12 a , a a W 0.886 4.64 a Y 3/ 2 W a W 1 W 2 P BW a 13 . 32 W 3 4 a a 14.72 5.60 W W 2 36 Mode-I SIFs for elliptical / semi-elliptical cracks Solutions valid if Crack small compared to the plate dimension a≤c When a = c , 0 Circular: KI 0.63 a 2 a (closed-form solution) Semi-circular: K I 0.72 a 37 Associated asymptotic mode I displacement field : Polar components : ur uθ K I 1 ν 2E K I 1 ν with 2E Cartesian components : r θ 3θ 2κ 1 cos cos 2π 2 2 ux KI 2 r cos 1 2 sin2 2 2 2 r θ 3θ 2κ 1 sin sin 2π 2 2 uy KI 2 r sin 2 2 1 2E shear modulus 2 1 2 cos 2 3 plane stress 1 3 4 plane strain E: Young modulus : Poisson’s ratio Displacement near the crack tip varies with r Material parameters are present in the solution 38 Ex: Isovalues of the mode-I asymptotic displacement: 2 u x K I 0.7 0.6 plane strain, =0.38 0.2 0.3 0.4 0.1 0 0.1 crack 0.2 0.3 0.4 0.5 2 u y K I 0.6 1 0.7 0.8 0.6 0.4 0.3 x= r cos 0.2 0.1 y=r sin y=r sin 0.5 crack 0 0.1 0.2 1 0.8 0.6 x= r cos 0.4 0.3 39 Mode II – loading Same procedure as mode I with the antisymmetric part of r a a Bsin Dsin 2 Asymptotic stress field : rr K II 2r 3 3 5 sin sin 4 2 4 2 K II 2r 3 3 3 sin sin 4 2 4 2 K II r 2r 3 3 1 4 cos 2 4 cos 2 40 Cartesian components: K II 3 sin 2 cos cos 2 2 2 2 r K II 3 sin cos cos 2 2 2 2 r xx yy xy K II 3 cos 1 sin sin 2 2 2 2 r Associated displacement field : ux K II 2 r sin 1 2 cos 2 2 2 2 uy K II 2 r cos 2 2 2 1 2 sin 2 41 Mode III – loading Stress components : rz K III θ sin 2 2π r K III θ θz cos 2 2π r 0 σ 0 rz 0 0 z rz z 0 Displacement component : uz 4K III E r θ 1 ν sin 2π 2 42 Closed form solutions for the SIF Mode II-loading : K II a Mode III-loading : K III a 43 Principe of superposition for the SIFs: n With n applied loads in Mode I, K total I K I(i) i 1 Similar relations for the other modes of fracture But SIFs of different modes cannot be added ! Principe of great importance in obtaining SIF of complicated specimen loading configuration Example: p p p (a) K (a) I K (b) (b) I p a 0 p f Q s (c) 44 4.5 Relationship between KI and GI: K I2 Mode I only : GI E' E' E E' E / 1 2 Plane stress Plane strain When all three modes apply : K I2 K II2 K III2 G E' E' 2 E / 2 1 Self-similar crack growth Values of G are not additive for the same mode but can be added for the different modes 45 Proof yy x KI a 2x U a 0 a G I lim in load control (ch 3) Work done by the closing stresses : a U dU x 1 with dU x 2 u y x yy x dx 2 0 but, u y x 1 KI a a 2 and also dU x 1 1 K I a a a x r 2 2 2 K I a K I a a a x dx 2 2 x slide 38, with 0 slide 32 for yy x Calculating U and injecting in GI GI 1 lim a 0 K I a K I a a a 4a 2 GI 1 K 2I 8 46 4.6 Mixed mode fracture biaxial loading e2 2 0 0 in global frame ( e1 e2 ) 1 → expressed in local frame ( e1 e2 ) e1 cos e1 sin e2 e2 sin e1 cos e2 e2 e1 e1 e1 e1 e1 e2 Q e2 e1 e2 e2 Thus, Q = Rotation tensor cos sin Q sin cos Stress tensor components : 2 1 K I(0) 1 a R 0 11 12 T 2 Q 0 Q 22 1 21 47 2 cos 2 2 sin cos 1 sin cos 11 12 1 sin2 sin cos sin2 2 2 2 22 21 1 sin cos 1 cos Mode I loading : 22 2 K (1) c os a I 1 K I(0) cos 2 K (2) 2 sin 2 a I RK I(0) sin 2 12 e2 e1 11 → Principe of superposition : K I K I(0) cos 2 R sin 2 Mode II loading : K I(0) cos sin K (1) II 1cos sin a RK I(0) cosβ sinβ K (2) II σ 2 cosβ sinβ πa K II K I(0) cosβ sinβ 1 R 48 Propagation criteria Mode I Crack initiation when the SIF equals to the fracture toughness K 2IC K I K IC or G I G IC ' E Mixed mode loading Self-similar crack growth is not followed for several material 2 K K 2I K 2II III K 2IC 1 Useful if the specimen is subjected to all three Modes, but 'dominated' by Mode I General criteria: K I , K II , K IC , K IIC , i ,...... 0 explicit form obtained experimentally 49 Examples in Modes I and II m n KI K II C0 1 K IC K IIC m , n and C0 parameters determined experimentally Erdogan / Shih criterion (1963): Crack growth occurs on directions normal to the maximum principal stress 3 3 K I sin sin K II cos 3cos 0 2 2 2 2 Condition to obtain the crack direction 50 4.7 Fracture toughness testing Assuming a small plastic zone compared to the specimen dimensions, a critical value of the mode-I SIF may be an appropriate fracture parameter : KC → plane strain fracture toughness KIC plane stress plane strain KC : critical SIF, depends on thickness KI > KC : crack propagation K IC Specimen Thickness KIC : Lower limiting value of fracture toughness KC Material constant for a specific temperature and loading speed 2 K IC GIC E Apparent fracture surface energy kJ / m 2 51 How to perform KIC measurements ? → Use of standards: - American Society of Testing and Materials (ASTM) - International Organization of Standardization (ISO) ASTM E 399 first standardized test method for KIC : CT - was originally published in 1970 - is intended for metallic materials - has undergone a number of revisions over the years - gives specimen size requirements to ensure measurements in the plateau region ASTM D 5045 -99 is used for plastic materials: - Many similarities to E 399, with additional specifications important for plastics. KI based test method ensures that the specimen fractures under linear elastic conditions (i.e. confined plastic zone at the crack tip) 52 Chart of fracture toughness KIC and modulus E (from Ashby) Large range of KIC 0.01->100 MPa.m1/2 At lower end, brittle materials that remain elastic until they fracture 53 Chart of fracture toughness KIC and yield strength Y (from Ashby) Materials towards the bottom right : high strength and low toughness →fracture before they yield Materials towards the top left : opposite → yield before they fracture Metals are both strong and tough ! 54 Typical KIC values: 1 MPa m 1 MN m3 / 2 55 Ex Aircraft components Fuselage made of 2024 alloy (Al + 4% Cu + 1% Mg) Thickness of the sheet ~ 3mm Y K IC KC 350 MPa (elastic limit) 30 MPa m AIRBUS A330 100 110 MPa m Plane stress criterion with Kc is typically used here in place of KIC 56