Document

advertisement

POLYCHAR 22 - Short Course

Michael Hess

DYNAMIC-MECHANICAL and

CALORIMETRIC

PROPERTIES OF POLYMERS

Thanks to Dr. Kevin Menard, University of North Texas and Perkin Elmer for some of the examples

Calorimetric Analysis of Polymers

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

course of polymerization

transreactions

chain scission

radiation induced degradation

thermal degradation

chain stripping leaving carbonaceous residue

curing of thermosets

...

phase behaviour (estimation of a phase diagram)

mesophase behaviour

(processing) history

(themoreversible) gelation

thermal transitions (Tg, Tm, Tcr...)

bound water in hydrogels

crystallization and ordering

...

Dynamic-Mechanical

Analysis

mechanical properties of (polymeric) materials under the influence of

dynamic load and temperature

mechanical modulus as a function of load, temperature, time

transitions, relaxations, service range (temperature), service time

Thermal Transitions

transition temperatures, transition enthalpie

glass transition

cold crystallization

•recrystallization

•crystallization

melting

•brittle/viscous

•miscibility

•thermal history

•polymorphism

•mesophases

•phase diagram

•kinetics

•degree of crystallization

•purity

DTA

DT

DSC

Wel (DT=0)

poly(dimethyl siloxane) (PDMS)

heat flux

or

cp

melting

Tm (end)

enthalpy relaxation

cold crystallization

Tg

Tm (onset)

Tm (rate max)

Dynamic-mechanical analysis - rheology

the modern machines can rapidly change the measuring device

so that solid and fluid samples can be measured

and many different modes can be applied

Thermomechanical Analysis

Stress-Strain Curves

Creep Recovery

Stress Relaxation

Dynamic Mechanical Analysis

Solvent Immersed testing

simple deformations in a solid

simple extension

simple shear deformation

(also in liquids possible)

simple stress in a shear deformation

ii = normal stress; ij = shear stress

22

21

12

32

23

2

1

3

33

31

13

11

The total stress ij is a second rank tensor composed of normal and

shear components

(ideal) energy elasticity

•caused by deformation of bond angles and bond length at small deformations

•the energy is stored and completely released after the load is removed

•there is no (internal) friction

=

Fnormal

= E

=

=

A0

1

E

=

L L0

L0

=

DL

L0

= 1

Fin plane

A0

= G

= J

= strain; = uniaxial deformation ratio; = shear (angle); F = force [N]; A0 = initial area

E = Young modulus [Pa]; G = shear modulus [Pa]; J = compliance [Pa-1]

Stress Causes Strain

Lo

elongationL-Lo = DL

L

Cauchy or

Engineering Strain

= DL/Lo

Hencky or

True Strain

= ln (DL/Lo)

Kinetic Theory

of Rubber Strain

= 1/3{L/Lo-(Lo/L)2}

Kirchhoff Strain

= 1/2{ (L/Lo)2-1}

Murnaghan Strain

= 1/2{1-(Lo/L)2}

The different definitions of tensile strain

become equivalent at very small deformations.

The stress [Pa = N/m2] refers to the initial cross section

Stress and strain are principally time-dependent

stress can “relax” (at constant strain)

elongation can “creep” (at constant stress)

ideal stress-strain diagram

inThe

the elastic limit: Hooke’s Law

=

slope = k

Strain increases

with increasing

Stress

Slope: elastic (Young-) modulus E

the major types of moduli

extension

Young modulus E

shear

shear modulus G

compression

bulk modulus B

bending*

bending modulus Eb

*three-point bending, 4 point bending

E = 2G 1 ) = 3 B 1 2 )

lat

=

long

The lateral strain lat is the strain

normal to the uniaxial deformation.

the different moduli can be converted into one another, see D. Ferry

so that for elastomers:

0.5E 3G

The volume change on deformation is for most elastomers negligible so that

=0.5 (isotropic, incompressible materials).

In a sample under small uniaxial deformation!!

The lateral strain lat is the strain

normal to the uniaxial deformation.

shear in an ideal (Newtonian) liquid

ideal liquid between

two parallel plates

an ideal liquid shows no elasticity

dilatant

grad v

= grad v =

dv

dx 2

= shear rate

=

= dynamic viscosity [Pa s]; 1 centipoise = 1 mPa s

structural

viscous

slope =

.

important rheometer types for viscous samples

torque

plate-plate

cone-plate

constant shear rate

along the radius

Couette

a combination of both:

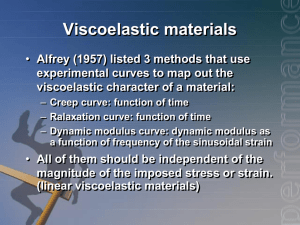

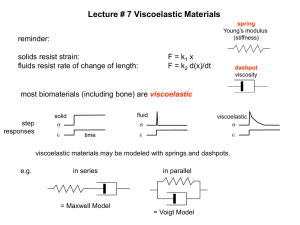

visco-elastic behaviour

James Clerk Maxwell, Phil. Trans. Roy. Soc. London 157 (1867) 52

single relaxation time

spectrum of relaxation times i

There is mater that shows elastic and viscous behaviour (e.g. pitch):

fast deformation rather elastic, slow deformation rather viscous response

major response types on deformational stress

storage and loss of energy

dissipated energy

Qrev = E '' 02

1

wrev = E

2

'

E”

2

0

Young’s modulus is

designed for elastic

materials. Real materials

consist of both elastic

and viscous response.

E” – lost to friction and

rearrangement - “the

Loss Modulus”

saved energy

E’

tan =

E ''

E'

E’ – stored and released –

“the Storage Modulus”

(conceptually like

Young’s Modulus)

damping (factor)

'simple' static stress-strain experiment

tensile strength

b

stress

= f , T )

= f t , T )

tensile strength

yield strength

brittleness B*):

B=

elongation at break

tensile strength

1

b E '

elongation at break

*) according to Brostow et al., J. Mater. Sci 21 (2006) 2422

not to be confused with the bulk modulus B (compression modulus)

strain

b

b

time

frequency dependence of damping

TTS

temperature

superposition

temperature depending properties (elasticity, flow…)

long term prediction, fatigue…

frequency range and applied technique

DMA relates:

product properties

molecular structure

Material

Behavior

processing conditions

Free damping experiment

An

=ln

A

n 1

amplitude

logarithmic decrement

shear (storage) modulus G'(f, T)

loss modulus G''(f, T)

loss factor D (tangent)

stress

strain

stress and strain are in phase in an ideal energy-elastic material,

phase angle = 0°

stress and strain are out of phase in an ideal viscous material,

phase angle = 90°

The modulus of a visco-elastic material is a complex physical entity

Theory shows that the modulus is complex and can be split into

a real part E ' and an imaginary part with E '':

0 i 0

0

0

= E * = e = cos i sin ) = cos i sin

0

0

0

0

E'

E ''

E * = E ' iE ''

1

wrev = E ' 02

2

Qrev = E '' 02

dissipated (loss)

stored

Because Young’s Modulus isn’t

enough…

E”

Young’s modulus is

designed for elastic

materials. Real materials

consist of both elastic

and viscous response.

E” – lost to friction and

rearrangement - “the

Loss Modulus”

E’

E’ – stored and released –

“the Storage Modulus”

(conceptually like

Young’s Modulus)

Correlation between moduli and phase angle (damping)

in the Gaussian plane of complex numbers the

complex shear modulus G*, the Young modulus E*

and the complex viscosity * can be visualized as

E* = ; G* = ; * =

the damping factor D is then given by the tan of

the loss angle

D= tan

D shows a behaviour similar to

Modulus, damping and their correlation with molecular motions

or tan

(rubber)

or tan

a thermodynamic view at the 'glass transition'

There is not only

one glass.

The type of glass

depends on the

thermal history.

slowly heating can cause

annealing

G'

The glass transition in a dynamic experiment

tan

G''

glassy

visco-elastic

rubbery

T

DMA and different molecular parameters

Curv e 1: DMA Temp/Time Scan in Extension

File inf o:

demof ilm

Wed Oct 11 17:06:48 1995

Frequency : 1.00 Hz

Amplitude: 21.949u

pet f ilm

Tension: 110.000%

# 1 pet f ilm:demof ilm

tan

Tg are easily seen, as in PET Film

# 2 Storage Modulus (Pa x 10

9

)

1.6

3.5

3.0

1.0

2.5

9

)

1.2

0.8

Onset 83.29

C

2.0

0.6

1.5

0.4

Onset 107.82

0.2

1.0

C

0.5

0.0

Onset 79.35

C

0.0

-100.0

0.0

100.0

Temperature (

TEMP1: -100.0 C

TEMP2: 250.0 C

TIME1: 0.0 min

RATE1: 10.0 C/min

200.0

C)

300.0

PERKIN-ELMER

7 Series Thermal

Analy sis Sy stem

Sun Nov 26 21:02:11 1995

Modulus (Pa x 10

tan

1.4

Tg by DMA and DSC

differential scanning calorimetry

Peak Tan = 140.5°C

Onset E’ = 133.1 °C

Tf

Heat flow/mW

Onset E” = 127.3 °C

Inflection Point

Onset

Onset Tan = 130.0 °C

Temperature /C

Temperature/C

(a)

(b)

DCp

DH/J/g)

Tan

Modulus/Pa

Peak E” = 136.7 °C

Operating Range by DMA

Curv e 1: DMA Temp/Time Scan in 3 Point Bending

File inf o:

gamma_1

Thu Jun 30 02:17:24 1988

Frequency : 7.00 Hz

Dy namic Stress: 1.86e+06Pa

EPOXY PC BOARD AT 7 Hz Static Stress: 1.86e+06Pa

# 1 EPOXY PC BOARD AT 7 Hz:gamma_1

10

Storage Modulus (Pa x 10

)

1.1

4.5

Tg

0.8

10

)

Operating

range

)

5.0

Beta

0.9

-1

(x 10

4.0

)

(b)

tan

3.5

2.5

Operating

range

0.5

0.4

2.0

1.5

1.0

0.2

0.5

0.1

0.0

0.0

-100.0

modulus is ok

Curv e 1: DMA Temp/Time Scan in 3 Point Bending

File inf o:

AMPf rPP.1 Wed Oct 27 13:49:06 1993

Frequency : 1.00 Hz

Dy namic Stress: 950.0mN

LeBrun samples

Static Stress: 1000.0mN

TIME1: 0.0 min

RATE1: 10.0 C/min

# 1 LeBrun samples:AMPf rPP.1

Storage Modulus (Pa x 10

tan

(x 10

-1

3.0

Operating

range

1.5

1.5

1.0

1.0

0.5

0.5

0.0

-150.0

-100.0

AMP Flame Retardant Poly propy lene

TIME1: 0.0 min

RATE1: 5.0 C/min

-50.0

0.0

Temperature (

50.0

C)

-1

leather-like state

(x 10

2.0

2.0

)

2.5

tan

9

)

200.0

PE DMA7 R&D LAB

PERKIN-ELMER

7 Series Thermal

Analy sis Sy stem

Sun Nov 26 20:13:53 1995

9

)

)

2.5

TEMP1: -160.0 C

TEMP2: 300.0 C

100.0

C)

toughness is ok

#2

Modulus (Pa x 10

0.0

Temperature (

TEMP1: -180.0 C

TEMP2: 300.0 C

100.0

KPM

PERKIN-ELMER

7 Series Thermal

Analy sis Sy stem

Sun Nov 26 20:58:36 1995

(x 10

3.0

0.6

tan

Modulus (Pa x 10

0.7

0.3

(c)

-1

(a)

-> # 2

1.0

temperature of use

shear modulus

rigid

blow

vacuum forming extrusion

'leather'

forming

injection moulding

rubber

viscous

amorphous

semicrystalline thermoplasts

shear modulus

temperature of use

extrusion

injection moulding

cold

forming

vacuum

forming

blow

forming

Cold Crystallization in PET seen by DMA and DSC

Tm

Tg

Cold Crystallization

DSC

Curv e 1: DMA Temp/Time Scan in 3 Point Bending

AMP66gp.1 Tue Oct 26 16:05:29 1993

File inf o:

Dy namic Stress: 190.0mN

Frequency : 1.00 Hz

Static Stress: 200.0mN

LeBrun samples

Higher Order Transitions affect toughness

LeBrun samples

4.0

5.5

5.0

3.5

4.5

)

-1

2.5

3.0

2.5

2.0

b Transitions

1.5

2.0

Tg

Poor

1.5

1.0

1.0

0.5

0.5

0.0

0.0

-150.0

-100.0

-50.0

AMP good part 20% glass f illed Ny lon 6/6

Impact was

good if Tg/Tb was 3 or less.

TEMP1: -160.0 C

TEMP2: 300.0 C

TIME1: 0.0 min

RATE1: 5.0 C/min

0.0

Temperature (

50.0

C)

100.0

150.0

KPM

PERKIN-ELMER

Analy sis Sy stem

7 Series Thermal

Sat Oct 15 14:32:54 1994

(x 10

Good Impact Strength

3.5

tan

Modulus (Pa x 10

9

)

3.0

4.0

stress-relaxation in a silicone rubber

DMTA

Tg

DSC

Cold Crystallization

Left: silicon rubber with a glass transition at –117°C and a melting transition at –40°C. Beyond the

melting temperature this crosslinked (vulcanised) material shows rubber-elasticity with modulus that

increases with the temperature.

Right: also a silicone rubber that contains silicone oil as diluent, as plasticizer. The oil causes a stressrelaxation at the beginning of the melting transition around –47°C.

Blends and Copolymers

Polymer A

Both Tgs

E’

E’

Block Copolymers

Graft Copolymers

Immiscible Blends

Temperature/K

Temperature/K

+

=

Single Tg

E’

E’

Polymer B

Exact T depends on

concentration of A and B

Temperature/K

Temperature/K

Random

Copolymers &

Miscible Blends

The frequency-dependence of dynamic experiments

Temperature dependency of E' and tan of PVC at different frequencies, after

Becker, Kolloid-Z.140 (1955) 1

Time-Temperature-Superposition Principle(TTS)

experimental

experimental

window

window

NBS-poly(isobutylene, after A. Tobolski

The glass transition temperature seen by viscosity

lg

empirical WLF equation

Tg+50K

Arrhenius-type

Temperature-dependence of the viscosity

of PMMA (M=63.000 g/mol) after Bueche

Williams-Landel-Ferry (WLF) equation

Ts )

20, 4 T Ts )

ln

= ln aT =

; Ts = Tg 50 ) K

)

T

102 T Ts

TTS gives the frequency-dependence

of the glass transition temperature:

lg AT

lim

T Tg T Tg

= 0.338

t

g

0.338T Tg ) = lg AT = lg = lg

t

g

g

lg

DT =

0.338

An increase of the measuring frequency (heating rate) by a factor 10 (or a decrease of

the time frame by a factor of 10) near Tg the glass-transition temperature is found about

3 K higher.

Master Curves*) extend the range

• We can collect data from 0.01 to 100 Hz.

• If we do this at many temperatures, we can

“superposition” the data.

TTS

• After TTS, our range is 1e-7 to 1e9 Hertz (1/sec)

• Then x scale (frequency) can then be inverted to get

time *) modulus or compliance; compliance = (modulus)-1

BUT...

TTS assumes that:

“all relaxation times are equally affected

by temperature.”

THIS IS KNOWN TO OFTEN BE

INVALID.

J. Dealy

Log J*

Failure of TTS

compliance J = 1/E

Analysis of a Cure by DMA

E’-E” Crossover ~ gelation point

10 8

10 7

Modulus

10 6

106 Pa ~ Solidity

10 5

vitrification point

E”

10 4

Curing

10 3

E’

10 2

Melting

Minimum Viscosity (time, length,

temperature )

10 1

10 0

50.0

70.0

90.0

110.0

130.0

150.0

T

experiment at a constant heating rate

time-temperature-transition diagram

after Gillham

Activation Energy tells us about the molecule

• For example, are these 2 Tgs or a Tg and a Tb?

Elastomer

Sample

• Because we can calculate the Eact for the peaks, we

can determine if both are glass transitions.

Determination of the apparent energy of activation

log f =

Ea 1

const .

R T

146.5 kJ/mol

351.7 kJ/mol

How can we do this experimentally??

MULTIPLEXING

Multiplexing…

Instead of just the Tg

Sheet

Film

Fiber

multiple frequencies in one run

Or you can use the Synthetic Oscillation Mode

Take five frequencies

Sum together

And

apply the

complex

wave

form to

the

sample

Temperature in C

Gelation Point by Multiplexing

We can then do further analysis

Activation energy

Master curve

PMMA

(0.01~100Hz)

Why?…

To Review, DMA ties together...

molecular structure

Molecular weight

MW Distribution

Chain Branching

Cross linking

Entanglements

Phases

Crystallinity

Free Volume

Localized motion

Relaxation Mechanisms

product properties

Material

Behavior

processing conditions

Stress

Strain

Temperature

Heat History

Frequency

Thermal

Pressure

Heat set

Dimensional Stability

Impact properties

Long term behavior

Environmental resistance

Temperature performance

Adhesion

Tack

Peel

Further Readíng

Kevin P. Menard, Dynamic-Mechanical Analysis, CRC-Press (1999) Boca Raton

W. Brostow, Performance of Plastics, Carl Hanser Verlag (2000) Munich

I. M. Ward, Mechanical Properties of Solid Polymers, Wiley (1983) New York

J. J. Aklonis, W. J. McKnight, Introduction to Polymer Viscoelasticity,

Wiley-Interscience (1983) New York

N. W. Tschloegl, The Theory of Viscoelastic Behaviour, Acad. Press (1981) New York

D. Ferry, Viscoelastic Properties of Polymers, Wiley (1980) New York

B. E. Read, G. D. Dean, The Determination of Dynamic Properties of Polymers and

Composites, Hilger (1978) Bristol

L. E. Nielsen, Polymer Rheology, Dekker (1977) New York

L. E. Nielsen, Mechanical Properties of Polymers, Dekker (1974) New York

L. E. Nielsen, Mechanical Properties of Polymers and Composites Vol. I & II,

Dekker (1974) New York

A. V. Tobolsky, Properties and Structure of Polymers, Wiley (1960) New York

Many examples by courtesy of Kevin Menard

(University of North Texas, Department of Materials Science

and Perkin Elmer Corp.)