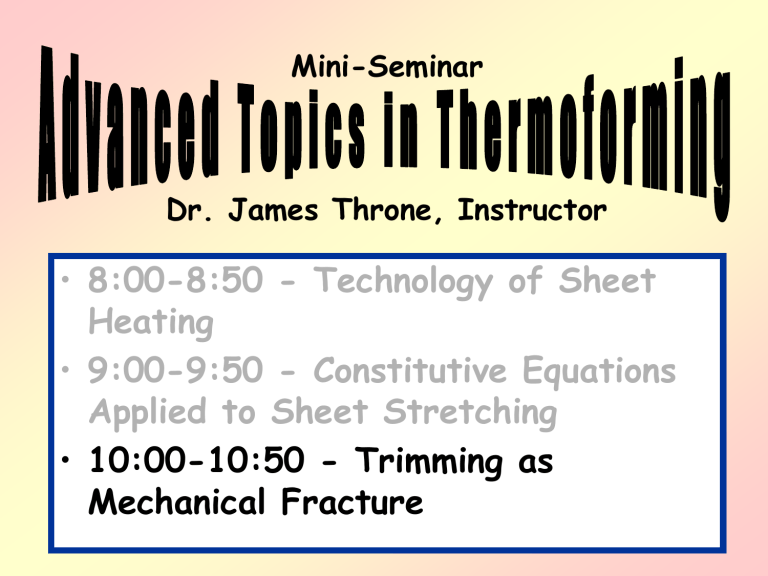

Mini-Seminar Advanced Topics in Thermoforming

Mini-Seminar

Dr. James Throne, Instructor

• 8:00-8:50 - Technology of Sheet

Heating

• 9:00-9:50 - Constitutive Equations

Applied to Sheet Stretching

• 10:00-10:50 - Trimming as

Mechanical Fracture

Mini-Seminar

Advanced Topics in Thermoforming

Part 3: 10:00-10:50

Trimming as Mechanical

Fracture

Let’s begin!

Mini-Seminar

Advanced Topics in Thermoforming

• All materials contained herein are the intellectual property of Sherwood Technologies, Inc., copyright

1999-2006

• No material may be copied or referred to in any manner without express written consent of the copyright holder

• All materials, written or oral, are the opinions of

Sherwood Technologies, Inc., and James L. Throne,

PhD

• Neither Sherwood Technologies, Inc. nor James L.

Throne, PhD are compensated in any way by companies cited in materials presented herein

• Neither Sherwood Technologies, Inc., nor James L.

Throne, PhD are to be held responsible for any misuse of these materials that result in injury or damage to persons or property

Mini-Seminar

Advanced Topics in Thermoforming

• This mini-seminar requires you to have a working engineering knowledge of heat transfer and stress-strain mechanics

• Don’t attend if you can’t handle theory and equations

• Each mini-seminar will last 50 minutes, followed by a 10-minute “bio” break

• Please turn off cell phones

• PowerPoint presentations are available at the end of this seminar for downloading to your memory stick

Mini-Seminar

Advanced Topics in Thermoforming

• For those concerned about hearing the plenary speaker at 1100 hours, please be assured that this miniseminar will end promptly at 1050 hours…

• And, if for some strange reason, it doesn’t, please feel free to leave…

• THERE WILL BE NO FINAL!

• You can download all PPTs at the end of this section

Part 3: Trimming as Mechanical Fracture

Outline

• Fundamentals

• Fracture mechanics

• The mechanics of trimming

• Trimming accuracy

• Thin-gauge trimming

• Heavy-gauge trimming

Part 3: Trimming as Mechanical Fracture

What is Trimming?

• Trimming is semi-controlled mechanical breaking

• The objective is to separate the formed part from the web, skeleton, unformed plastic around it

• The methods of trimming are strongly dependent on sheet thickness

• Trimming can be manual or robotic, it can take place on the mold surface or in a remote fixture

Part 3: Trimming as Mechanical Fracture

Traditional trimming methods

• Manual - knives, serrated for foam

• Routers - hand-held, table-mounted fixed- position, multi-axis

• Band saws

• Circular saws - stationary, hand-held small- diameter, toothless saws for foam

• Abrasive wheels

Part 3: Trimming as Mechanical Fracture

Traditional trimming methods, cont.

• Sharp-edged compression blades or dies - steel-rule, ground forged, machined

• Linear shear guillotines - one-sided, two-sided

• Flames

• Lasers

• Water jets

Part 3: Trimming as

Mechanical Fracture

Traditional

Trimming

Methods

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

Three general fracture modes

• Mode I - tensile mode, fracture surfaces spread apart by stress

• Mode II - shear mode, fracture surfaces slide perpendicular to advancing crack

• Mode III - tearing mode, fracture surfaces spread by stress parallel to crack

Part 3: Trimming as Mechanical Fracture

Mechanics of

Fracture

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

• Mode III is a shearing action. Guillotine cutting of heavy gauge sheet and punch-and-die cutting of thin gauge sheet are Mode III

• Mode I is a compressing action. In-place trimming of thin-gauge sheet is Mode I

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

Force needed to initiate a crack is substantially less than theoretical cohesive strength of polymer

Cracks initiate at flaws or defects

Consider a polymer having a small crack a in length under plane stress (Griffith crack theory)

EG *

a

K

C

a where E is Young’s modulus and ...

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

EG *

a

K

C

a

G* is the fracture energy, given as G* = 2(P+ g ) where P is the plastic work done during yielding, g is the surface energy of the polymer,

K c is the fracture toughness or stress intensity factor

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

EG *

a

K

C

a

Polymers with low P/ g ratios are brittle

(PMMA~5)

Polymers with very high P/ g ratios are ductile

(vulcanized rubber ~ 500)

It is nearly always the case that the energy to initiate a fracture is far greater than that needed to sustain crack propagation

Part 3: Trimming as Mechanical Fracture

K c

Mechanics of Fracture is the fracture toughness or stress intensity factor. It is written as K c

= f( ,a ) or

K c

C

a

C depends on crack geometry and surface being fractured

Polymer

PS

HIPS

PE

K c

(1000 lb/in 3/2 )

19.8

104

31.2

PMMA 19.8

Part 3: Trimming as Mechanical Fracture

Mechanics of Fracture

An aside

• Nanoparticles have initial sizes substantially below the Griffith crack criterion

• As a result, theoretically, fracture is unlikely to initiate on a nanoparticle

• Meaning that, theoretically, nano-filled polymers should have impact strengths equal to those of the polymers themselves

• The functional word here is “theoretically”

Part 3: Trimming as Mechanical Fracture

Mechanics of Trimming

Five general mechanisms

1. Mode I

In-plane unaxial compression

(die-cutting)

Part 3: Trimming as Mechanical Fracture

Mechanics of Trimming

Five general mechanisms

2. Mode III antiplane pure shear

(nibbling, shear cutting, punch and die)

Part 3: Trimming as Mechanical Fracture

Mechanics of Trimming

Five general mechanisms

3. Abrasion or abrasive cutting (grinding, filing,buffing, water jet cutting)

Part 3: Trimming as Mechanical Fracture

Mechanics of Trimming

Five general mechanisms

4. Brittle tensile fracture (routing, drilling, sawing)

Part 3: Trimming as Mechanical Fracture

Mechanics of Trimming

Five general mechanisms

5. Thermal

(hot knife, hot wire, laser cutting)

Part 3: Trimming as Mechanical Fracture

Trim Tolerance Limitation

• Local polymer shrinkage

• Polymer morphology

• Time-dependent part shrinkage after trimming

• Ductility of polymer

• Fixture/part rigidity

• Part temperature variation at trim line

• Registry accuracy

Part 3: Trimming as Mechanical Fracture

Trim Tolerance Limitation, cont.

• Trim die temperature variation

• Part thickness, thickness variation

• Allowable wall thickness variation at trim line

• Die gap setting temperature v. trim die temperature

• Clamp frame stiffness

• Die flexing during trimming

Part 3: Trimming as Mechanical Fracture

•

•

•

•

•

•

•

Factors in Selecting a Trimming Technique

Sheet gauge

Part size

Number of parts

Overall draw ratio

Nonplanar nature of trim line

Cut surface roughness tolerance

Dimensional tolerance

Part 3: Trimming as Mechanical Fracture

•

•

•

•

•

•

Factors in Selecting a Trimming Technique, continued

Required speed of trimming

Extent of fixturing

Number of secondary operations [drilling, machining]

Skill of operator/pressman

Availability of desired trim equipment

Availability of resharpening methods

Part 3: Trimming as Mechanical Fracture

•

•

The mechanics of trimming depends on the sheet gauge

Thin-gauge trimming

Heavy-gauge trimming

Part 3: Trimming as Mechanical Fracture

Thin Gauge

Steel rule die cutting

1. In place, on the mold, in-situ

2. In machine, separate station

3. In line, separate machine

Part 3: Trimming as Mechanical Fracture

1. In-place trimming with steel-rule die

Part 3: Trimming as

Mechanical Fracture

Thermoforming –

1. Form and inplace trimming

[GN]

Part 3: Trimming as Mechanical Fracture

2. In-machine, usually with stacker

Part 3: Trimming as Mechanical Fracture

3. In-line trimming with canopy punch and die

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Primary methods

1. In-plane uniaxial compression or die-cutting

Cutting stress, = E e , where E is elastic tensile modulus and e is extent of strain

Solid compressibility is reciprocal of bulk modulus,

B which is related to the elastic tensile modulus:

E = 3B(1-2 n ) where n is Poisson’s ratio, 0.3 < n <

0.4

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Primary methods

2. Mode III antiplane pure shear or punch-anddie cutting

Shearing stress, under shear force

= G e s

, where G is the modulus of rigidity or shear modulus and e s is strain

Shear modulus is related to tensile modulus:

G = E/2(1+ n ) where n is Poisson’s ratio, 0.3 < n <

0.4

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Primary methods – Compared

PA

HDPE n

Values for Poisson’s ratio

=0.33

n =0.35

PMMA

LDPE

Average n =0.35

n n

=0.33

=0.38

For average, E/G = 2.7, E/B = 0.9

Shear cutting force about 40% of that of compression cutting force (on average)

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Polymer response to compression cutting

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Polymer response to compression cutting of brittle polymers

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

•

•

•

Compression cutting required force is function of

Trim length

Polymer type

Polymer temperature

•

• Trim die temperature

Sharpness of die

General equation:

F (force/unit length of trim) = a + b (polymer thickness)

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming

Various steel rule die designs

Curve D is for dulled version of cutter B

RPVC

PS

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming- 1

Steel rule die cutting force as function of cutter temperature, F = a + b(tk)

Polymer

(

Cutter

Temp o C) a

(lb f

/in) b

(lb f

/in 2 )

Force @

40 mils

(lb f

/in)

Pct

Reduction

_______________________________________________________________

HIPS 20 7.2 1231 56.4 -

HIPS 80 14.1 539 35.7 37

ABS

ABS

RPVC

RPVC

20

80

20

80

13.4

12.4

21.5

16.5

943

647

1078

746

51.1

38.3

64.6

46.3

-

25

-

28

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming- 2

Steel rule die cutting force as function of cutter temperature, F = a + b(tk)

Polymer

(

Cutter

Temp o C) a

(lb f

/in) b

(lb f

/in 2 )

Force @

40 mils

(lb f

/in)

Pct

Reduction

_______________________________________________________________

HDPE 20 19.5 917 56.2 -

HDPE

HoPP

80

20

80

25.1

23.7

26.0

486

934

503

44.5

61.6

46.1

21

-

24 HoPP

PET

PET

20

80

35.6

37.0

1258

989

85.9

76.6

-

11

PC

PC

20

80

39.0

32.9

970

835

77.8

66.3

-

15

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming- 1

Steel rule die cutting force as function of sheet thickness, cutter temp = 20 o C, F = a + b(tk)

Polymer a

(lb f

/in) b

(lb f

/in 2 )

Force @

20 mils

Force @

40 mils

Force @

60 mils

(lb f

/in) (lb f

/in) (lb f

/in)

_______________________________________________________________

HIPS 7.2 1231 31.8 56.4 81.1

ABS

RPVC

PC

13.4

21.5

39.0

943

970

1078

32.3

43.1

58.4

51.1

64.6

77.8

70.0

86.2

97.2

PET 35.6 1258 60.8 85.9 111.1

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming- 2

Steel rule die cutting force as function of sheet thickness, cutter temp = 20 o C, F = a + b(tk) competitive packaging polymers

Polymer a

(lb f

/in) b

(lb f

/in 2 )

Force @

20 mils

(lb f

/in)

Force @

40 mils

(lb f

/in)

Force @

60 mils

(lb f

/in)

_______________________________________________________________

HIPS 7.2 1231 31.8 56.4 81.1

HoPP

RPVC

PET

23.7

21.5

35.6

934

1078

1258

42.4

43.1

60.8

61.6

64.6

85.9

79.7

86.2

111.1

Part 3: Trimming as Mechanical Fracture

Force required to compression-trim thin-gauge packaging plastics

Plastic

HIPS ABS RPVC PC PET hoPP

120

100

80

60

40

20

20 40 60

Based on experimental data, plotted as Force/inch =a + b(thickness)

Part 3: Trimming as Mechanical Fracture

Thin-gauge trimming -Example

Calculate the force required to die-cut 10-in x

10-in trays, 9-up from 40 mil sheet of a)

HIPS, b) PET

Trim length- 4 x 10 x 9 = 360 inches a) HIPS - 56.4 lb f tons

/in x 360 = 20,304 lb f b) PET - 85.9 lb tons f

/in x 360 = 30,924 lb f

= 10

= 15.5

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

• Hand-trimming using saws, routers

• Automated, programmable multiaxial routers that include saws, drills

Part 3: Trimming as

Mechanical Fracture

Heavy-gauge trimming

• Within the past decade, CNC-driven multi-axis routers, borrowed from the woodworking industry, have become standard fare for high quality part production in heavy-gauge forming.

• 5-axis router - Quintax

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

• “Three-Dimensional Trimming & Machining - The

Five Axis CNC Router”, K.J. Susnajara,

Thermwood Corporation, 1999

• Contents

– Machine Basics

– CNC Router Design

– Holding the Part

– Tooling

– Programming

– Accuracy

– Economics

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• First Layer

– Single v. multiple axis repeatability

– Absolute positioning accuracy - Single v. multiple axis

– Loaded v. unloaded repeatability, accuracy

– Machine considerations

• Lead screw backlash

• Rotary resolution of servomotor

• Encoder resolution and stepping interval

• Rail linearity

• Machine alignment [square and perpendicular]

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• First Layer

– Machine Design

• Lead screw backlash

• Rotary resolution of servomotor

• Encoder resolution and stepping interval

• Rail linearity

• Machine alignment [square and perpendicular]

• Head alignment - effect of crashes

• Head worm spur gear tooth accuracy, backlash

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• Second Layer

– Servo System Tracking

– Inertia during acceleration, deceleration

– Vibration, push-off, flexing

– Speed

– Tool length accuracy

– Tool-to-collet tightening

– CAD/CAM interpretation of curves [splines]

– Trimming of part v. computer trim path

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• Third Layer

– Overall part size variability

• Molding temperature

• Raw material formulation

• Cooling characteristics

– Polymer flexing under trim load

– Bridge flexing during carriage movement

– Dynamic flexing and bending v. speed

– Polymer reaction to push-off

– Bending, flexing of tool under load

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• Third Layer

– Thermal exansion, contraction

• Different materials in router

• Polymers being trimmed

• Tool dimensional change during trimming

– Polymer warping, distortion during trimming

– Trim direction v. “grain” in polymer

Part 3: Trimming as Mechanical Fracture

Accuracy

Heavy-gauge trimming

• Conclusion - Repeating an accurate

position in space is far easier than achieving that accurate position in space.

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

The mechanics of chip-breaking

[Saws, drills, routers, mills]

Chip

Cutter

Work

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Factors Affecting Cutting Characteristics of Plastics

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Multiple Edged Tool Cutting

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Multiple Edged Tool Cutting

Tooth depth of cut, g is: g = V p sin f /U

V is the feed rate, p is the tooth spacing, U is the peripheral blade speed, U=pDN, D is the diameter of the cutting blade, N is the blade speed (RPM).

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Multiple Edged Tool Cutting

The angle f is given as f = cos -1 [(h-b/2)/R] where h is the cut-off height or distance between the saw centerline and the bottom of the plastic sheet, b is the sheet thickness, R is the saw radius, R = D/2

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Multiple Edged Tool Cutting

Feed rate, V, proportional to blade speed, N, and diameter, D

Feed rate, V, inversely proportional to tooth spacing, p

[Arithmetic holds for multiple-edge routers as well]

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Drilling

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Drilling

Depth of cut per drill tooth, d: d = (s/n) sin q /2 = (V/nN) sin q /2 n is number of teeth on drill (one or two), N is the drill speed, V is the axial feed rate, s is drill feed speed, s = V/N, and q is the point tooth angle

Part 3: Trimming as Mechanical Fracture

Heavy-gauge trimming

Effect of Drill Geometry on Drilling Conditions

Drill Parameter Drill Condition

Point angle

Rake angle

Rotational drill speed

Drill feeding speed

Relief angle

Helix angle

Shape of flutes

Work temperature

Cooling provisions

Nature of the hole

Part 3: Trimming as Mechanical Fracture

End of

Part 3

Trimming as

Mechanical Fracture

Part 3: Trimming as Mechanical Fracture

End of

Mini-Seminar

Mini-Seminar

Advanced Topics in

Thermoforming