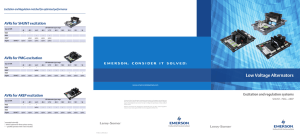

PMG Excitation

advertisement

EXCITATION SYSTEM SHUNT Excitation AVR power supply & reference voltages. shunted on the alternator output terminals. AVR generates and regulates the excitation current as a function of the alternator output voltage. Extremely simple design and ideal for basic applications. Cannot tolerate high overloads. Does not offer a short-circuit capability. PMG Excitation Alternator same design as SHUNT. AVR powered by a permanent magnet generator (PMG). PMG delivers constant voltage independent of the main winding. The voltage reference is shunted on the alternator output terminals. Suitable for demanding applications. PMG system has a high overload capacity Improved performance over SHUNT system. AREP Excitation The AVR power supply voltage comes from 2 independent auxiliary windings. AVR power supply is independent of the voltage sensing measured on the alternator output. Excitation current to the alternator exciter is independent of voltage distortions (harmonics) due to the load. AREP system gives high overload capacity & short-circuit capability. Particularly suitable for demanding applications EXCITATION SYSTEMS PMG ADVANTAGES DISADVANTAGES AREP SE High starting capacity High starting capacity Short-circuit capability Short-circuit capability Self protected against short circuit Intrinsic build-up No extra length No extra length Extra length Specific winding No short- circuit capability High number of components Small added cost Low starting capacity Added cost Sensitive to distorting loads if thyristor controlled VOLTAGE (V) SE CHARACTERISTIC ( or auxiliary winding H1/ AREP) AREP/ PMG CHARACTERISTIC AREP SERIES ( Auxiliary winding H3/ AREP) SUSTAINED VOLTAGE DIP LOAD % 100% LOW OVERLOAD 200% 300% HIGH OVERLOAD - SHORT CIRCUIT 3-Phase PMG Excited, 3-Phase Sensing 3-Phase Self Excited, 3-Phase Sensing 3-Phase AREP Excited, 3-Phase Sensing EFFECT OF DRILLING RIG LOAD ON ALTERNATOR DESIGN DRILLING RIG: A drilling rig creates a borehole, or well, where oil and natural gas can be extracted for the production of fuels and other petroleum-based products. Drilling rigs may be described as mechanical or electric. These terms refer to the method in which power is supplied to the larger equipment on the rig. On mechanical rigs, power from the engines drives the rig equipment either directly, through a clutch or through a torque converter. Electric rigs use engine power to drive one or more generators. The generated electricity is then used to operate motors for the larger equipment on the rig. There are three types of electric rigs: DC (Direct Current) SCR (Silicon Control Rectifier) VFD (Variable frequency Drive) ELECTRIC RIG: Electric motors power the draw works, rotary table, pumps and other systems with electricity from the generator. These applications are called electric drilling rigs or electric rigs. The electric motors used for hoisting, drilling and pumping require high torque at zero rpm and variable speed characteristics for efficient operation. These characteristics are possible using the following methods: Direct Current (DC) Generators Alternating Current (AC) Generators with Silicon Controlled Rectifiers (SCR) AC Generators with Variable Frequency Drive (VFD) Motors GENERATOR SIZING A rig operating with the power limiter light on does not mean the engines are being efficiently operated. Larger kVA generators (or other remedial action) may be needed because generators may be at kVA limit and engines at only 30 to 50% load. A difficulty in efficiently sizing and operating an SCR or DC rig is the common assumption that “x” amperes represents “y” power; this is not true. If power factor is 1.0, then “x” amperes represents “y” power. At power factors below 1.0, power is less than the amperes indicate. A power factor from 0.3 to 0.9 on an SCR rig, under steady-state conditions, is evidence that generator sizing is important. During hoisting, power factor varies from 0.0 to 0.95. There may be cases where the minimum number of engines cannot be operated because of a high generator kVA requirement. Before examining these variables, it is first necessary to review some characteristics of DC motors DC Motor Characteristics The rpm of DC motors is primarily controlled by the voltage to the motor (recognizing that motor type series, shunt and control system field weakening, etc. is related factors). Ampere draw of the motor controls torque output of the motor. This leads to the realization that a DC motor can work hard at low rpm (draw high amperage and produce high torque) and not load the engine (but load the generator) when operating at low DC voltage/low rpm. A method to calculate AC generator power factor due to current draw of a DC motor powered through an SCR system. Mentioned graph the effect of motor rpm (or DC voltage) on the power factor of the driving AC generators. For a constant rpm (DC voltage), power factor is the same from no load to full load. The best way to improve system power factor is to ensure that DC motors are run at as high an rpm as possible. Every DC ampere presents a 0.85 kVA load on the generator, regardless of DC power. Operating a DC motor at high rpm reduces ampere load, therefore kVA