From Ink-Jet Technology to Nano Array Writing Technology

advertisement

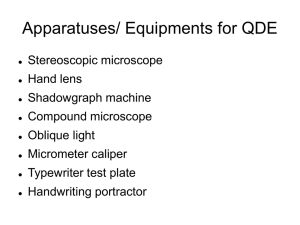

From Ink-Jet Technology to Nano Array Writing Technology By Szu-kang Hsien Ayodeji Coker OVERVIEW Objective. Approach. Our Nano Array Writing Device. Conclusion. Acknowledgements. OBJECTIVE The use of nano-technology and microfabrication techniques for nano array writing. Replacing conventional lithography methods with nano array writing capable of producing 30nm line widths. The independent control of each AFM tip used in the nano-array writing technology using comb-drive actuators. APPROACH Using the concept employed in Dip Pen Nanolithography (DPN) for nano array writing. Using ink-jet technology as a mode of delivering ink to an AFM tip capable of writing line widths on the order of nano-meters. Motion control in the x-y-z plane is done using comb-drive and electrostatic actuators. INK JET TECHNOLOGY Drop On Demand (DOD) ink-jet printing is to be utilized in our device. A high voltage is to be applied to a PZT crystal causing it to bend. This effect in turn applies a pressure on the ink reservoir. As a result of the applied pressure, the reservoir jets out ink on demand, in our case to coat the AFM tip. Schematic of Ink delivery structure Ink Reservoir piezoelectric material Drive circuit Ink writing substrate AFM tip INK JET TECHNOLOGY A change in voltage gives rise to a corresponding change in force and the resulting dimensional change in length. V=dijFjx/(orA) F will be 0.11 N using PZT film dimension 100m*100m, r=3000, d11=370 pC/N, d31=110 pC/N, V=10V and x = 2m. The displacement of the crystal, L= LV/(td31), will be around 0.2m. So we can stack around 5 PZT crystals together in order to have 1m pressing into the ink DIP-PEN NANOLITHOGRAPHY (DPN) Old technique of dip pen writing. In place of the nib used in the regular dip-pen, an AFM tip is employed. Using ink-jet technology, “ink” is transported to the AFM tip, which it coats. The ink is delivered to the substrate, by choosing an “ink” and substrate that have an affinity for one another e.g ODT and Au. AFM Tip Writting Direction Molecular Transport Water Meniscus Au Substrate ATOMIC FORCE MICROSCOPE (AFM) AFM relies on a scanning technique to to produce very high resolution 3-D images of sample surfaces. There are three methods used in AFM applications. They are the contact mode, the intermittent contact mode and the non contact imaging. The method employed NAWT is the intermittent contact mode method. Force vs. distance curve showing tip sample Separation of different AFM operating modes. Schematic of AFM x z Sample y Deflection Sensor Tip xyz Translator Lever Constant F COMB DRIVE AND ELECTROSTATIC ACTUATORS A large number of fine interdigiated fingers are actuated by applying a voltage between them. This will provide the x-y motion for our device. The z-motion is achieved by electrostatically actuating the cantilever on which the AFM is attached. Comb Drive Actuators Our Nano Array Writing Device Ink Jet Structure. Scream Process for the fabrication of the comb drive actuators. AFM tip fabrication. 3-D image of our nano array writing device. Ink Jet Fabrication (a) p++ Si PZT Al Inte r co nne ct (d) Ink Si (b) (e ) Flow Chann e l Ink Ink Inle t Or ifice (c) LPCV D SiO2 PZT Ink Noz z le Ink Inle t Or ifice Persepective view Scream Process p h o to r e s is t ( a) (e ) SiO2 Si Ph o to lit h o g r ap h y Re m o ve f lo o r Oxid e (f) (b) Si Se co n d Silico n e t ch Pat t e r n T r an s f e r ( c) (g) De e p Si e t ch SF6 Re le as e (d) PECV D SiO 2 Sid e w all Oxid e d e p o s it io n ( PECV D) (h) M e t alliz at io n b y s p u tt e r in g AFM tip Fabrication (c) (a) Saw Cut Glas s M as k ing m ate r ial (SiO 2) Cr Si Bonding (b) (d) s aw cut Si3N4 Si3N4 Gl ass an d C r r emoved 100 m (e ) m e tal fr e e cantile ve r tip 3-D Structure Of Our Device Comb Drive Cantilever beam AFM Tip Ink channel Electrode to control Z Drive Circuit piezoelectric material Ink Reservoir Conclusion Technology is feasible. NAWT is a faster way of doing lithography. Comb drive in Collaboration with electrostatic cantilever deflection is a good method of control in all 3 dimentions. Acknowledgements. Prof. Horacio Espinosa for his guidance and advice. Prof. Chad Mirkin for taking time to provide us with all the necessary information on DPN. Zhu the TA for all the literature and help he gave us.