Knitting Science 2, Production Calculation

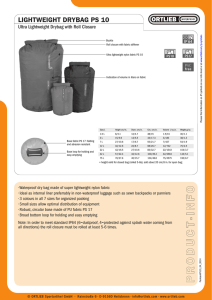

advertisement

Knitting Science (2) Jimmy Lam Institute of Textiles & Clothing Learning Objectives Tightness factor and fabric properties Maximum cover factor Application of fabric geometry Tightness factor and fabric properties Physical properties of the fabric that related to cover factor or tightness factor: – – – – – transparency and air permeability; shrinkage of a fabric pilling and snagging effect flexural rigidity and extension tightly or slackly of fabric Transparency and air permeability Since the value of tightness factor can show the openness of the fabric, ie the higher the tightness factor, the lower the openness of the fabric Also the openness of the fabric is directly related to transparency and air permeability. Therefore, the higher the value of tightness factor, the lower of the transparency and air permeability character or vice versa. Shrinkage of fabric If the same type of yarn is used, the tighter the fabric (or higher the tightness factor), the lower the shrinkage of the fabric. It is because the tightly knitted fabrics simply cannot shrink as much as before adjacent loops jam against each other. Pilling an snagging effect Since the tightly knitted fabric, the movement of fabric or yarn is more difficult than snack fabric, therefore the pilling or snagging is more difficult to occur in the tightly knitted fabric. It is because the effect of pilling and snagging is determined by the movement of fiber or yarn. Flexural rigidity and extension The higher the tightness factor of the fabric shows the higher the flexural rigidity and lower the extension properties of the fabric Tightly or slackly fabric They are related to the handle of the fabric. As said previously, the higher the tightness factor, the tighter the fabric or vice versa. Also if the fabric is tightly knitted, the hand feels of the fabric is not so soft. However, a tightly knitted fabric gives a better fabric dimensional stability. Maximum Cover Factor Maximum Cover For a maximum cover, an equilateral triangle is constructed. CD2 = BC2 - BD2 = 1-(1/2)2 CD=Sqrt(3/4) = 0.866 Since AB is wale width and CD is course depth; the max cover is – wale width : course depth = 1: 0.866 Max Cover (2) As wales per unit length and courses per unit length are equal to the reciprocals of wales width and course depth, therefore wales/unit length : courses/unit length = 0.866:1 That is, 86 wales to 100 courses in the plain fabric is the condition to have maximum cover in a plain knitted fabric Application of fabric geometry Fabric weight per unit area Fabric weight per unit area (g/m2) – let S is stitches per cm2; – l is loop length in mm; and – T is yarn count in Tex No. of stitches in 1 m2 = S x104; Fabric weight = S x 104 X l/1000 X T/1000 – As S=Ks/l2; – g/m2= Ks/l2 X 104 X l/1000 X T/1000 g/m2=Ks T/(100l) Fabric weight per running meter Running meter is one meter length of fabric measured along the direction of production irrespective of width. Number of courses in one meter = cpcm X 100 If n is no. of needles, total stitches = n X cpcm X 100 g/m = n X cpcm X 100 X l/1000 X T/1000 – Since cpcm= Kc/l – g/m = n X Kc/l X 100 X l/1000 X T/1000 g/m = nKcT/10000 Fabric Width Width = number of needles in knitting / W = n/ W where W is wales per unit width (wpcm) Since W=Kw/l Width = nl/Kw Fabric length Fabric length = number of feeders X rpm /C – where C is course per unit length Since C=Kc/l fabric length = Feeder X rpm X time taken (min) X l / Kc