Pneumatic facts

advertisement

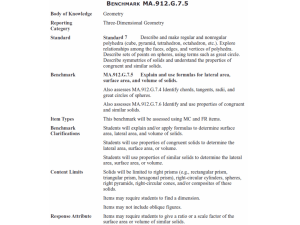

Facts and Theory of Air For industrial pneumatics Contents Composition of air Atmospheric pressure Industrial compressed air Pressure Pressure units Pressure and force The gas laws Constant temperature Constant pressure Constant volume General gas law Adiabatic compression Water in compressed air Low temperature drying Flow of compressed air Air quality Click the section to advance directly to it Composition of air The air we breathe is springy, squashy and fluid in substance We take it for granted that wherever there is space it will be filled with air Air is composed mainly of nitrogen and oxygen Composition by Volume Nitrogen 78.09% N2 Oxygen 20.95% O2 Argon 0.93% Ar Others 0.03% Atmospheric pressure The atmospheric pressure is caused by the weight of air above us It gets less as we climb a mountain, more as we descend into a mine The pressure value is also influenced by changing weather conditions Standard Atmosphere A standard atmosphere is defined by The International Civil Aviation Organisation. The pressure and temperature at sea level is 1013.25 milli bar absolute and 288 K (15OC) 1013.25 m bar ISO Atmospheres ISO Recommendation R 554 Standard Atmospheres for conditioning and/or testing of material, components or equipment 20OC, 65% RH, 860 to 1060 mbar 27OC, 65% RH, 860 to 1060 mbar 23OC, 50% RH, 860 to 1060 mbar Tolerances ± 2OC ± 5%RH Reduced tolerances ± 1OC ± 2%RH Standard Reference Atmosphere to which tests made at other atmospheres can be corrected O 20 C, 65% RH, 1013 mbar No qualifying altitude is given as it is concerned only with the effect of temperature, humidity and pressure Atmospheric pressure We see values of atmospheric pressure on a weather map The lines called isobars show contours of pressure in millibar These help predict the wind direction and force 1015 mb 1012 mb 1008 mb 1000 mb 996 mb LOW Mercury barometer Atmospheric pressure can be measured as the height of a liquid column in a vacuum 760 mm Hg = 1013.9 millibar approximately A water barometer tube would be over 10 metres long. Hg = 13.6 times the density of H2O For vacuum measurement 1 mm Hg = 1 Torr 760 Torr = nil vacuum 0 Torr = full vacuum 760 mm Hg Atmosphere and vacuum The power of atmospheric pressure is apparent in industry where pick and place suction cups and vacuum forming machines are used Air is removed from one side allowing atmospheric pressure on the other to do the work Pressures are in “bar g” gauge pressure ( the value above atmosphere) Zero gauge pressure is atmospheric pressure Absolute pressures are used for calculations Pa = Pg + atmosphere For quick calculations assume 1 atmosphere is 1000 mbar For standard calculations 1 atmosphere is 1013 mbar 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Gauge pressure bar g Absolute pressure bar a Industrial compressed air 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Extended Industrial range Typical Industrial range Low range Atmosphere Full vacuum Pressure 1 bar = 100000 N/m2 (Newtons per square metre) 1 bar = 10 N/cm2 For measuring lower pressures the millibar (mbar) is used 1000 mbar = 1 bar For measurements in pounds per square inch (psi) 1 psi = 68.95mbar 14.5 psi = 1bar Pressure units There are many units of pressure measurement. Some of these and their equivalents are listed below. 1 bar = 100000 N/m2 1 bar = 100 kPa 1 bar = 14.50 psi 1 bar = 10197 kgf/m2 1 mm Hg = 1.334 mbar approx. 1 mm H2O = 0.0979 mbar approx. 1 Torr = 1mmHg abs (for vacuum) More units of pressure Pressure and force Pressure and force Compressed air exerts a force of constant value to every internal contact surface of the pressure containing equipment. Liquid in a vessel will be pressurised and transmit this force For every bar of gauge pressure, 10 Newtons are exerted uniformly over each square centimetre. Pressure and force D mm The thrust developed by a piston due to air pressure is the effective area multiplied by the pressure D2 P p Thrust = Newtons 40 Where D = The bore of a cylinder in mm P = The pressure in bar. We require an answer in Newtons 1bar = 100000 N/m2 D2 is therefore divided by 1000000 to bring it to m2 and P is multiplied by 100000 to bring it to N/m2. The result is a division by 10 shown in the product 40 above P bar Pressure and force The force contained by a cylinder barrel is the projected area multiplied by the pressure l D Force = D . l . P Newtons 10 Where D = the cylinder bore mm l = length of pressurised chamber mm P = the pressure in bar Pressure and force If both ports of a double acting cylinder are connected to the same pressure source, the cylinder will move out due to the difference in areas either side of the piston If a through rod cylinder is applied in this way it will be in balance and not move in either direction Pressure and force In a balanced spool valve the pressure acting at any port will not cause the spool to move because the areas to the left and right are equal and will produce equal and opposite forces P1 and P2 are the supply and exhaust pressures P1 P2 Pressure and force In a balanced spool valve the pressure acting at any port will not cause the spool to move because the areas to the left and right are equal and will produce equal and opposite forces P1 and P2 are the supply and exhaust pressures P2 P1 Pressure and force In a balanced spool valve the pressure acting at any port will not cause the spool to move because the areas to the left and right are equal and will produce equal and opposite forces P1 and P2 are the supply and exhaust pressures P1 P2 The gas laws The gas laws For any given mass of air the variable properties are pressure, volume and temperature. By assuming one of the three variables to be held at a constant value, we will look at the relationship between the other two for each case Constant temperature Constant pressure P.V = constant V = constant T Constant volume P T = constant Constant Temperature Constant temperature Boyle’s law states: the product of absolute pressure and volume of a given mass of gas remains constant if the temperature of the gas remains constant. This process is called isothermal (constant temperature). It must be slow enough for heat to flow out of and in to the air as it is compressed and expanded. Pressure P bar absolute 16 14 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 Volume V P1.V1 = P2.V2 = constant Constant temperature Boyle’s law states: the product of absolute pressure and volume of a given mass of gas remains constant if the temperature of the gas remains constant. This process is called isothermal (constant temperature). It must be slow enough for heat to flow out of and in to the air as it is compressed and expanded. Pressure P bar absolute 16 14 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 Volume V P1.V1 = P2.V2 = constant Constant temperature Boyle’s law states: the product of absolute pressure and volume of a given mass of gas remains constant if the temperature of the gas remains constant. This process is called isothermal (constant temperature). It must be slow enough for heat to flow out of and in to the air as it is compressed and expanded. Pressure P bar absolute 16 14 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 Volume V P1.V1 = P2.V2 = constant Constant temperature Boyle’s law states: the product of absolute pressure and volume of a given mass of gas remains constant if the temperature of the gas remains constant. This process is called isothermal (constant temperature). It must be slow enough for heat to flow out of and in to the air as it is compressed and expanded. Pressure P bar absolute 16 14 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 Volume V P1.V1 = P2.V2 = constant Constant temperature Boyle’s law states: the product of absolute pressure and volume of a given mass of gas remains constant if the temperature of the gas remains constant. This process is called isothermal (constant temperature). It must be slow enough for heat to flow out of and in to the air as it is compressed and expanded. Pressure P bar absolute 16 14 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 Volume V P1.V1 = P2.V2 = constant Constant Pressure Constant pressure Charles’ law states: for a given mass of gas at constant pressure the volume is proportional to the absolute temperature. Assuming no friction a volume will change to maintain constant pressure. From an ambient of 20oC a change of 73.25oC will produce a 25% change of volume. 0o Celsius = 273K Temperature Celsius 100 80 60 40 293K 20 0 -20 -40 -60 0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 Volume V1 V2 = =c T1(K) T2(K) Constant pressure Charles’ law states: for a given mass of gas at constant pressure the volume is proportional to the absolute temperature. Assuming no friction a volume will change to maintain constant pressure. From an ambient of 20oC a change of 73.25oC will produce a 25% change of volume. 0o Celsius = 273K Temperature Celsius 100 366.25K 80 60 40 20 0 -20 -40 -60 0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 Volume V1 V2 = =c T1(K) T2(K) Constant pressure Charles’ law states: for a given mass of gas at constant pressure the volume is proportional to the absolute temperature. Assuming no friction a volume will change to maintain constant pressure. From an ambient of 20oC a change of 73.25oC will produce a 25% change of volume. 0o Celsius = 273K Temperature Celsius 100 80 60 40 20 0 -20 -40 -60 219.75K 0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 Volume V1 V2 = =c T1(K) T2(K) Constant pressure Charles’ law states: for a given mass of gas at constant pressure the volume is proportional to the absolute temperature. Assuming no friction a volume will change to maintain constant pressure. From an ambient of 20oC a change of 73.25oC will produce a 25% change of volume. 0o Celsius = 273K Temperature Celsius 100 366.25K 80 60 40 293K 20 0 -20 -40 -60 219.75K 0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 Volume V1 V2 = =c T1(K) T2(K) Constant volume Constant volume From Boyle’s law and Charles’ law we can also see that if the volume of a given mass of air were to be kept at a constant value, the pressure will be proportional to the absolute temperature K. For a volume at 20oC and 10 bar absolute a change in temperature of 60oC will produce a change in pressure of 2.05 bar 0oC = 273K Temperature Celsius 100 80 60 40 20 8 6 0 -20 4 12 2 14 0 -40 -60 10 bar 16 bar absolute 0 5 10 15 20 P1 P2 = =c T1(K) T2(K) Constant volume From Boyle’s law and Charles’ law we can also see that if the volume of a given mass of air were to be kept at a constant value, the pressure will be proportional to the absolute temperature K. For a volume at 20oC and 10 bar absolute a change in temperature of 60oC will produce a change in pressure of 2.05 bar 0oC = 273K Temperature Celsius 100 80 60 40 20 8 6 0 -20 4 12 2 14 0 -40 -60 10 bar 16 bar absolute 0 5 10 15 20 P1 P2 = =c T1(K) T2(K) Constant volume From Boyle’s law and Charles’ law we can also see that if the volume of a given mass of air were to be kept at a constant value, the pressure will be proportional to the absolute temperature K. For a volume at 20oC and 10 bar absolute a change in temperature of 60oC will produce a change in pressure of 2.05 bar 0oC = 273K Temperature Celsius 100 80 60 40 20 8 6 0 -20 4 12 2 14 0 -40 -60 10 bar 16 bar absolute 0 5 10 15 20 P1 P2 = =c T1(K) T2(K) Constant volume From Boyle’s law and Charles’ law we can also see that if the volume of a given mass of air were to be kept at a constant value, the pressure will be proportional to the absolute temperature K. For a volume at 20oC and 10 bar absolute a change in temperature of 60oC will produce a change in pressure of 2.05 bar 0oC = 273K Temperature Celsius 100 80 60 40 20 8 6 0 -20 4 12 2 14 0 -40 -60 10 bar 16 bar absolute 0 5 10 15 P1 P2 = =c T1(K) T2(K) The general gas law The general gas law is a combination of Boyle’s law and Charles’ law where pressure, volume and temperature may all vary between states of a given mass of gas but their relationship result in a constant value. P1 .V1 P2 .V2 = = constant T1 T2 Adiabatic and polytropic compression For compressed air Adiabatic compression bar a In theory, when a volume of air is compressed instantly, the process is adiabatic (there is no time to dissipate heat through the walls of the cylinder) 16 PV 1. 4 = c 14 adiabatic 12 PV 1. 2 = c 10 polytropic 8 PV = c 6 isothermal 4 2 0 0 2 4 6 8 10 12 14 16 Volume For adiabatic compression and expansion P V n= c for air n = 1.4 In the cylinder of an air compressor the process is fast but some heat will be lost through the cylinder walls therefore the value of n will be less 1.3 approximately for a high speed compressor Polytropic compression In practice such as in a shock absorbing application there will be some heat loss during compression The compression characteristic will be somewhere between adiabatic and isothermal The value of n will be less than 1.4 dependent on the rate of compression. Typically PV 1.2 = c can be used but is applicable only during the process Water in compressed air Water in compressed air fully saturated air Condensate Drain When large quantities of air are compressed, noticeable amounts of water are formed The natural moisture vapour contained in the atmosphere is squeezed out like wringing out a damp sponge The air will still be fully saturated (100% RH) within the receiver Water in compressed air The amount of water vapour contained in a sample of the atmosphere is measured as relative humidity %RH. This percentage is the proportion of the maximum amount that can be held at the prevailing temperature. Temperature Celsius 25% RH 50% RH 100% RH 40 At 20o Celsius 100% RH = 17.4 g/m3 50% RH = 8.7 g/m3 25% RH = 4.35 g/m3 20 0 -20 -40 0 10 20 30 40 50 60 70 80 Grams of water vapour / cubic metre of air g/m3 Water in compressed air The illustration shows four cubes each representing 1 cubic metre of atmospheric air at 20oC. Each of these volumes are at a relative humidity of 50% (50%RH). This means that they actually contain 8.7 grams of water vapour, half of the maximum possible 17.4 grams Water in compressed air When the compressor squashes these four cubic metres to form one cubic metre there will be 4 times 8.7 grams, but only two of them can be held as a vapour in the new 1 cubic metre space. The other two have to condense out as water droplets Water in compressed air When the compressor squashes these four cubic metres to form one cubic metre there will be 4 times 8.7 grams, but only two of them can be held as a vapour in the new 1 cubic metre space. The other two have to condense out as water droplets Water in compressed air When the compressor squashes these four cubic metres to form one cubic metre there will be 4 times 8.7 grams, but only two of them can be held as a vapour in the new 1 cubic metre space. The other two have to condense out as water droplets Water in compressed air When the compressor squashes these four cubic metres to form one cubic metre there will be 4 times 8.7 grams, but only two of them can be held as a vapour in the new 1 cubic metre space. The other two have to condense out as water droplets Water in compressed air When the compressor squashes these four cubic metres to form one cubic metre there will be 4 times 8.7 grams, but only two of them can be held as a vapour in the new 1 cubic metre space. The other two have to condense out as water droplets Water in compressed air 4 cubic metres at 50%RH and 1000 mbar atmospheric pressure contained in the space of 1 cubic metre produce a pressure of 3 bar gauge 17.4 grams of water remain as a vapour producing 100% RH (relative humidity) and 17.4 grams condense to liquid water This is a continuous process, so once the gauge pressure is over 1 bar, every time a cubic metre of air is compressed, and added to the contained 1 cubic metre, a further 8.7 grams of water are condensed Low temperature drying Low temperature drier Humid air enters the first heat exchanger where it is cooled by the dry air going out The air enters the second heat exchanger where it is refrigerated The condensate is collected and drained away As the dry refrigerated air leaves it is warmed by the incoming humid air Humid air in Dry air out M Refrigeration plant Drain Low temperature drying If 1 cubic metre of fully saturated compressed air ( 100 % RH ) is cooled to just above freezing point, approximately 75% of the vapour content will be condensed out. When it is warmed back to 20OC it will be dried to nearly 25% RH Temperature Celsius 25% RH 50% RH 100% RH 40 20 0 -20 -40 0 10 20 30 40 50 60 70 80 Grams of water vapour / cubic metre of air g/m3 Low temperature drying If 1 cubic metre of fully saturated compressed air ( 100 % RH ) is cooled to just above freezing point, approximately 75% of the vapour content will be condensed out. When it is warmed back to 20OC it will be dried to nearly 25% RH Temperature Celsius 25% RH 50% RH 100% RH 40 20 0 -20 -40 0 10 20 30 40 50 60 70 80 Grams of water vapour / cubic metre of air g/m3 Low temperature drying If 1 cubic metre of fully saturated compressed air ( 100 % RH ) is cooled to just above freezing point, approximately 75% of the vapour content will be condensed out. When it is warmed back to 20OC it will be dried to nearly 25% RH Temperature Celsius 25% RH 50% RH 100% RH 40 20 0 -20 -40 0 10 20 30 40 50 60 70 80 Grams of water vapour / cubic metre of air g/m3 Flow of compressed air Flow units Flow is measured as a volume of free air per unit of time Popular units are : 1 m3/m = 35.31 scfm 1 dm3/s = 2.1 scfm 1 scfm = 0.472 l/s 1 scfm = 0.0283 m3/min 1 litre or cubic decimetre Litres or cubic decimetres per second l/s or dm3/s Cubic metres per minute m3/m Standard cubic feet per minute (same as cubic feet of free air) scfm 1 cubic foot 1 cubic metre or 1000 dm3 Free air flow The space between the bars represents the actual volume in the pipe occupied by 1 litre of free air at the respective absolute pressures. Flow takes place as the result of a pressure differential, at 1bar absolute (0 bar gauge) there will be flow only to a vacuum pressure If the velocity were the same each case will flow twice the one above Actual volume of 1 litre of free air at pressure 0 1 litre 1bar a 1/ 2bar a 1/ 4bar a 1/ 8 8bar a 1/ 16bar a 16 4 2 Sonic flow The limiting speed at which air can flow is the speed of sound For sonic flow to exist, P1 must be approx. 2 times P2 or more 1.894 When exhausting air from a reservoir at high pressure to atmosphere the flow will be constant until P1 is less than 2 P2 When charging a reservoir the flow will be constant until P2 is 1/2 P1 9 8 7 6 5 P1 bar 4 absolute 3 2 1 0 0 9 8 7 6 P2 bar absolute 5 4 3 2 1 0 0 P1 is 9 bar a reservoir to atmosphere 2P2 atm 5 10 time 15 20 1/ P 2 1 P1 is 9 bar a source to reservoir atm 5 10 15 20 Flow through valves Valve flow performance is usually indicated by a flow factor of some kind, such as “C”, “b”, “Cv”, “Kv” and others. The most accurate way of determining the performance of a pneumatic valve is through its values of “C” (conductance) and “b” (critical pressure ratio). These figures are determined by testing the valve to ISO 6358 For a range of steady source pressures P1 the pressure P1 P2 P2 is plotted against the flow through the valve until it reaches a maximum The result is a set of curves showing the flow characteristics of the valve Flow through valves From these curves the critical pressure ratio “b” can be found. “b” represents the ratio of P2 to P1 at which the flow velocity goes sonic. Also the conductance“C”at this point which represents the flow “dm³/ second / bar absolute” 0.5 Critical pressure ratio b = 0.15 Conductance C= 0.062 dm/s/bar a For the horizontal part of the curve only Flow 0.4 dm3/s free 0.3 air 0.2 P1 is the zero flow point for each curve 0.1 0 0 1 2 3 4 5 Downstream Pressure P2 bar gauge 6 7 Flow through valves If a set of curves are not available but the conductance and critical pressure ratio are known the value of flow for any pressure drop can be calculated using this formulae P2 Q = C P1 1- Where : P1 = upstream pressure bar P2 = downstream pressure bar C = conductance dm3/s/bar a b = critical pressure ratio Q = flow dm3/s P1 2 -b 1-b Air Quality Air filtration quality ISO 8573-1 Compressed air for general use Part 1 Contaminants and quality classes Allowable levels of contamination are given a quality class number Specified according to the levels of these contaminants: solid particles water oil An air quality class is stated as three air quality numbers e.g. 1.7.1 solids 0.1 µm max and 0.1 mg/m 3 max water not specified 0.01 mg/m3 max This is the filtration class resulting from a Norgren Ultraire Filter To obtain pressure dew points that are low, also use an air drier Compressed air quality ISO 8573-1 Class 1 2 3 4 5 6 7 Solids Water Oil particle concentration size max maximum µm mg/m3 Max Pressure Dew point OC concentration mg/m3 – 70 – 40 – 20 0.01 0.1 1 5 25 - 0.1 1 5 15 40 - 0.1 1 5 8 10 - +3 +7 + 10 Not Specified Pressure dew point is the temperature to which compressed air must be cooled before water vapour in the air starts to condense into water particles End Pressure units Standard Atmosphere = 1.01325 bar abs Technical Atmosphere = 0.98100 bar abs 1 mm Hg = 1.334mbar approx. 1 mm H2O = 0.0979 mbar approx. 1 kPa = 10.0 mbar 1 MPa = 10 bar 1 kgf/cm2 = 981 mbar 1 N/m2 = 0.01 mbar 1 Torr = 1mmHg abs (for vacuum) Pressure units 1 bar = 100000 N/m2 1 bar = 1000000 dyn/cm2 1 bar = 10197 kgf/m2 1 bar = 100 kPa 1 bar = 14.50 psi 1 bar = 0.98690 standard atmospheres Pressure units 1 dyn/cm2 = 0.001mbar 1 psi = 68.95mbar Standard atmosphere = 14.7 psi approx. Standard atmosphere = 760 Torr approx. 1 inch Hg = 33.8 mbar approx. 1 inch H2O = 2.49mbar approx. 100 mbar is about as hard as the average person can blow Temperature conversion 393 373 240 220 120 100 200 353 180 80 160 333 140 60 120 313 100 40 80 293 273 60 40 20 253 0 20 OK -40 OF 0 -20 -20 233 -40 OC The absolute temperature scale is measured in degrees Kelvin OK On the Celsius scale 0OC and 100OC are the freezing and boiling points for water OK = OC + 273.15 The Fahrenheit and Celsius scales coincide at - 40O OF = OC. 9/ + 32 5 Click the arrow to return