Forestry 485

advertisement

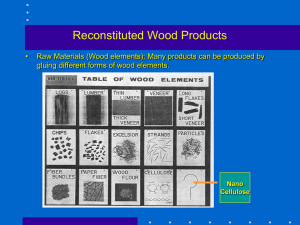

Forestry 485 Lecture 3-2: Resorcinol, melamine, and isocyanate adhesives Important Wood Adhesives We have seen that UF and PF are the primary wood adhesives, with usage of >1.5 and 1.0 x 109 dry pounds annually in the U.S., respectively Related adhesive systems occupy special niches, e.g., resorcinol and melamine A different (chemically speaking) type of adhesive, isocyanate (or MDI) is rapidly growing in importance, particularly for OSB. Resorcinol Formaldehyde (RF) Resorcinol is closely related to phenol in terms of chemical structure Resorcinol has two aromatic OH groups, versus one for phenol This renders resorcinol much more reactive than phenol Resorcinol plus formaldehyde at room temperature reacts quickly to form a gel…this “one stage” system is unsuitable for wood adhesives RF Synthesis Does this structure remind you of anything you’ve seen before? RF Cure High reactivity (10-15x PF) precludes formation of resoles Will cure at room temperature-useful for large gluelam beams Two-part system used for finger jointing lumber RF Characteristics Room temperature cure Short pot life, generally 2-4 hours High bond strength (fully structural) Works well for difficult-to-bond substrates, such as fire retardant or preservativetreated wood (FPL has developed activating systems for these applications) Dark reddish-brown glueline Phenol-resorcinol formaldehyde (PRF) Resorcinol is expensive compared to phenol Since the two are very similar chemically, phenol and resorcinol may be combined to form a hybrid PRF adhesive system Example: RF may be added as a “hardener” to resole PF at the time of use. Melamine Formaldehyde (MF) Like UF, this is an “amine formaldehyde” resin Unlike UF, MF forms fully waterproof bonds MF and UF may be blended to form “fortified UF” or “melamine-urea formaldehyde (MUF)” resins to take advantage of MF adhesive qualities and low cost advantage of UF Melamine formaldehyde synthesis Note that methylolation and polymerization occur in similar fashion to UF. As for UF, an acidic hardener is added to initiate polymerization. MF Characteristics High water resistance, high strength, high cost, colorless Has short storage life in liquid form; usually supplied as powder Used widely for surface coatings and laminates Increased use in recent years for composite flooring. MF content upwards of 30% in these applications Europeans make wide use of MF for exterior products (e.g., hardboard siding) Isocyanate Adhesives Isocyanates are a separate class of thermosetting adhesives Isocyanate R-N=C=O where R is aliphatic or aromatic Aromatic isocyanates are more important as wood adhesives Polyurethanes are also based on the chemistry of these materials Isocyanates: Generated from toluene diamine and phosgene Toluene diisocyanate – volatile; not used for wood adhesives Diphenylmethane diisocyanate – has low volatility, an important wood adhesive Isocyanate=MDI Two isocyanates are important as wood adhesives: 4, 4’ diphenylmethane diisocyanate 4,4’,4’’ triphenylmethane triisocyanate Wood adhesives are a mixture of such polymers and are generally called Polymeric Isocyanates or pMDI(s) or MDI(s) or simply isocyanate(s). Cure Reaction of Isocyanate Adhesives R-N=C=O + HO-R’ R-NHC=O OR’ urethane Isocyanate groups react with hydroxyls to form a urethane bridge. Such reactions theoretically possible with wood hydroxyls; chemical evidence is limited, however. Advantages of MDI Dry strength comparable to other resins MDI water resistance good; >UF, but < PF long-term No water in resin formulation, thus it is possible to use higher MC furnish Low resin application rates (typically <4%) Can bond difficult materials, such as ag particles (e.g., straw particleboard) Disadvantages of MDI High cost Bonds to metal; must use platen release agent or use only as core resin Has low vapor pressure (this is an advantage), but vapors are irritating to skin and eyes Airborne MDI aerosols/blended particulates can cause respiratory problems Sticks in resin blenders…many factories use jackhammers to periodically clean out blenders