Presentation - The BioCompactor Company

advertisement

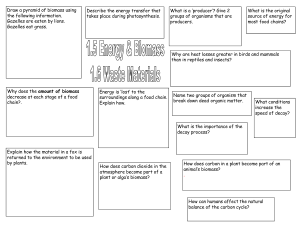

The BioCompactor Technology An Economic Solution to Dry and Densify Ligno-Cellulosic Biomass The BioCompactor Company, LLC Herbaceous Feedstock Logistics BioBriquet® The BioBriquet Production System BioBriquet® BioBriquet One line produces between 12,000 to 15,000 tons per year Works with most types of biomass waste and ag residue Can effectively process biomass residues with up to 65% moisture content Low energy consumption: 150 Kva Low maintenance cost and easy to replace wearable components Automated production system 2 HOW TO TURN AG RESIDUES INTO A VIABLE ENERGY COMMODITY: Reduce Handling Costs Reduce Shipping Costs Reduce Drying & Densifications Costs Attractive to Producer to Participate 3 CORN FIELDS CORN STOVER or other crops BioBriquet Factory INDUSTRIAL PLANT BioBriquet® BioBriquets (43 lbs/ft3) Burn alone or with coal Turn into cellulosic ethanol Ideal for gasification for CHP 4 ECONOMIC CONSIDERATIONS Feedstock Area Trucking Costs BioBriquet Plant Feedstock Requirements Feedstock area within 10-15 mile radius of plant to keep trucking costs low (at $0.25 p/T p/mile trucking cost= $67.50 on max load of 27T p/10 miles = $2.50 p/T 5 FEEDSTOCK REQUIREMENTS 1 BioBriquet plant produces between 12,000 to 15,000 MT of BioBriquets yearly (higher rates with dryer material - higher the MC the more material is required ) FEEDSTOCK AREA 100% Dedicated area = Approximately 50 Circles or 6,000 acres. (Realistic Estimate around 150 to 200 Circles with an estimated 20% farmer participation) Area production will depend on possible crop mixes. (Crop rotation with different harvest times), and also on regional factors for different crops & outputs. TRUCKING COSTS Keep within a 10–15 mile radius of the plant to keep costs low 6 Biomass requirements This is a function of the amount of water in the biomass. To compact correctly the biomass must have at least 8-10% MC Biomass with a MC of 15% or lower can be fed directly into the compactor without going through the dryer. Biomass above 65% MC can be processed but will slow production down considerably. As a rule of thumb approximately 8-12% of the fines of the feedstock input will be burned up running the dryer. The BioBriquets that are produced have between 8-14% MC 7 Volume comparison: Moist Stover vs. BioBriquets Moist Stover Calorific comparison / m³: Moist Stover vs. BioBriquets Moist Stover 50% moisture content 2,500 BTUs per lb BioBriquets 10% moisture content 7,500 BTUs per lb BioBriquets 8 9 BioBriquets Corn cobs/Stover dried and compacted for storage and transportation 10 ADVANTAGES OF THE BIOCOMPACTOR PRODUCTION SYSTEM OVER PELLETIZING Much more energy efficient BioBriquet energy production cost @ U$4 to U$6 per ton Pellet energy production cost @ U$9 to U$11 per ton One production line operates on less than 150Kva-average around 120Kva x 0.6 power factor= 72Kw p/hr Unique drying system uses just the biomass fines as fuel Eliminates a lot of dirt and rocks from the biomass before compacting when going through the dryer In pelletization biomass with dirt and rocks goes directly to the hammermill, then to the pellet mill, and this excess silica leads to equipment wear and tear Cost for BioBriquet equipment spare parts is around U$5 per ton 11 REPLACEMENT PARTS 1 - Supplies. Consumables: should be changed periodically, with an estimated lifetime of: Screw Injection ....................= ± 3000 tons Injection Pipe Thread ...........= ± 3000 tons Tool Chamber ......................= ± 3000 tons Piston Compressor …............= ± 1,500 tons Piston Tip …...........................= ± 250 tons Nut ….....................................= ± 125 tons Cone …..................................= ± 166 tons Tube Wear ….........................= ± 500 tons Note: The amount of tons produced before the spare parts wear out will vary depending on the abrasiveness of biomass. 12 One Stop Shop Turnkey Operation Easy to ship – One complete equipment line fits into one 40ft container + one 40ft flat-rack. Easy to assemble – plant is operational within 14 days. Modular and scaleable. Automated production system. 13 BioBriquet Dryer Exposed Dryer Dryer enclosed in insulated encasing 14 The BioCompactor 15 Control Panel Registers all the processes. Built-in safety features to avoid human error. 16 Touch Screen Control Panel 17 200 ton BioBriquet bags 200 ton BioBriquet bags Plant layout 18 Two line layout 200 ton BioBriquet bags 19 Labor requirements Labor required for 1 production line: 3 operators. With an additional operator can run two lines set together. 20 Equipment Cost One complete line with one year spare parts US$ 1,500,000 Personnel training and equipment assembly included 21 CONTINENTAL TECHNOLOGIES & BIOENERGY INVESTMENTS Continental Technologies specializes in developing cost effective, safe and optimized production processes and equipment. BioEnergy Investments brought the initial biomass densification technology to the USA. The two companies formed The BioCompactor Company in 2011 to produce and sell this innovative equipment. 22