Simplex Method for Linear Programming

advertisement

Chapter 4 Simplex Method for

Linear Programming

Shi-Shang Jang

Chemical Engineering Department

National Tsing-Hua University

Example 1: Inspector Problem

Assume that it is desired to hire some inspectors for monitoring

a production line. A total amount of 1800 species of products

are manufactured every day (8 working hours), while two

grades of inspectors can be found. Maximum, 8 grade A

inspector and 10 grade B inspector are available from the job

market. Grade A inspectors can check 25 species/hour, with

an accuracy of 98 percent. Grade B inspectors can check 15

species/hour, with an accuracy of 95 percent. Note that each

error costs $2.00/piece. The wage of a grade A inspector is

$4.00/hour, and the wage of a grade B inspector is $3.00/hour.

What is the optimum policy for hiring the inspectors?

Problem Formulation

Assume that the x1 grade A inspectors x2 grade B inspects

are hired, then

total cost to be minimized

48 x1 +38 x2 +2580.022 x1 +1580.052 x2

=40 x1 +36 x2

manufacturing constraint

258 x1 +158 x2 1,800 200 x1 +120 x2 1,800

no. of inspectors available:

0 x1 8

0 x2 10

The Graphical Solution

15

10

X2=10

B(8,10)

C(3,10)

+3

X1

40

6X

+3

5X 1

=Z

2

40

6X

5

00

=6

+3

X1

=4

X2

5

=5

=2 Z

00

X1=8

0

38

Z=

(8,5/3)

5

10

Theorem

Property: If there exists an optimal solution

to a LP, then at least one of the corner point

of the feasible region will always qualify to be

an optimal solution.

Special Cases

Alternate Solutions (non-unique solutions)

Max x1+2x2

s.t. x1+2x210

x1+ x21

x24

x10, x20

X2

5

4

X2=4

X+

1

2X

2 =1

0

X+

1

X+

1 2

X

2X

=

2

6

2 =2

+X

X1

X1

=2 1

6

10

Special Cases - continued

Unbounded Optima : A system has a feasible

region with open boundaries such that the

optima may appear at the infinity.

Example: For the previous example, in case

the constraint x1+2x210 is not given, then

moving far away from the origin increases

the objective function x1+2x2, and the maxim

Z would be +

Unbounded Optima

5

x2=4

4.5

x1+2x2=15

4

3.5

x2

3

x1+2x2=10

2.5

2

x1+2x2=6

1.5

x1+2x2=2

1

0.5

0

0

x1+x2=1

1

2

3

4

5

x1

6

7

8

9

10

Example 2: Student Fab

The RIT student-run microelectronic

fabrication facility is taking orders for four

indigenously developed ASIC chips that can

be used in (1) touch sensors ($6, s4hr, m1hr,

v30), (2)LCD($10,s9hr, m1hr, v40), (3)

pressure sensors($9, s7hr, m3hr, v20), and

(4) controllers($20, s10hr, m8hr, v10).

Constraints : Student hr≦ 600, machine

hr≦420, space≦800

The LP Problem

max 6 x1 10x2 9 x3 20x4

x

s.t.4 x1 9 x2 7 x3 10x4 600

x1 x2 3 x3 8 x4 420

30x1 40x2 20x3 10x4 800

4-2 The Basic Approach

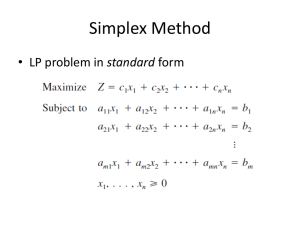

Standard Form of Linear Programming

min y c1 x1 c2 x2 cn xn

x1 , x2 ,, xn

s.t. a11 x1 a12 x 2 a1n xn b1

a 21 x1 a 22 x2 a 2 n xn b2

a m1 x1 a m 2 x 2 a mn xn bm

x1 , x2 ,, xn 0,

b1 , b2 , , bm 0, n m

Handling of in-equality Constraints

Case 1: Slack Variable:

x1+2x2+3 x3 +4x425

–

Modified to

x1+2x2+3x3+4x4+ x5=25

x50 is a slack variable.

Case 2: Surplus Variable:

2 x1+ x2-3 x312

Modified to

2 x1+ x2-3 x3- x4=12

x40 is a surplus variable.

–

Handling of Equality Constraints

If s is unrestricted, i.e., s can be positive or

negative, then we set

s=s+-ssuch that s+0, s- 0.

Example

max z x1 2 x 2 3 x3

s.t. x1 x 2 x3 7

x1 x 2 x3 2

3 x1 x 2 3 x3 5

x1 , x 2 0

Modify to

max z x1 2 x 2 3 x 4 3 x5

s.t. x1 x 2 x 4 x5 x6 7

x1 x 2 x 4 x5 x7 2

3 x1 x 2 3 x 4 3 x5 5

x1 , x 2 , x 4 , x5 , x6 , x7 0

Definitions

Definition: A feasible region, denoted by S is the set of all

feasible solution. Mathematically, . S x Ax b, x 0

Definition: An optimal solution is a vector x*S, s.t. z0=cTx* is

maximum or minimum in where Z is termed by the optimal

value.

Definition: Alternate optimal solution is a set XS, s.t. all xX

has the same objective value z0 and for all xS, and z=cTx, z

z 0.

Definition: If the solution set of LP contains only one element,

it is termed the unique optimum.

Definition: If the optimum value z approaches to infinity, then

the LP is said to have unbounded optimum.

4-3 The Simplex Method

min y c1 x1 c2 x2 c n x n

x1 , x2 ,, xn

s.t. a11 x1 a12 x2 a1n xn b1

a 21 x1 a 22 x2 a 2 n xn b2

a m1 x1 a m 2 x2 a mn xn bm

x1 , x2 ,, xn 0

Gauss Jordan Elimination and

ArtificialVariable Approachfor theconstraints

x1 a1,m1 xm1 a1s x s a1n xn b1

x2 a 2,m1 xm1 a 2 s x s a 2 n xn b2

xm a m,m1 xm1 a ms x s a mn xn bm

CanonicalForm

Definitions

Definition: A pivot operation is sequence of elementary row

operations that reduce the coefficients of a specified variable to

unity in one of the equation and zero elsewhere.

Definition: In the above canonical form, x1,,xm are termed the

basic variables or dependent variables, xm+1, ,xn are called

nonbasic variables or the independent variables.

Definition: The solution obtained from a canonical form is by

setting the nonbasic variable or independent variable to zero is

called a basic solution.

Definition: A basic feasible solution is a basic solution in which

the basic or dependent variables are non-negative.

Property

Remark:

where

n

n!

no.of basic solutions

m m!(n m)!

basic xi bi

Definition:

, i 1,, m, nonbasic xi 0, j m 1,, n

x B x1 ,, xm , c B c1 ,, cm

Property: A feasible basic solution is a simplex of the feasible region.

Note: Given a canonical form and feasible basic solution,

m

then the objective function:

T

z c B b B ci bi

i 1

where xB is a basic variable.

Approach (Simplex Method):

Start with an initial basic feasible solution in

canonical form.

Improve the solution by finding another basic

feasible solution if possible.

When a particular basic feasible solution is found,

and cannot be improved by finding new basic

feasible solution, the optimality is reached.

Definition: An adjacent basic solution differs from a basic

solution is exactly one basic variable.

Question: If one wants to find an adjacent feasible basic

solution from one feasible basic solution (i.e., switch to

another simplex), which adjacent basic solution gives lowest

objective function?

Derivation of Inner Product Rule

x1 a1s x s b1

x 2 a 2 s x s b2

xm a ms x s bm

Supposing, one wants to replace one of the original basic variable with

nonbasic variable xs, we firstly, increase xs from zero to one,

then for all i=1,,m,

xi bi a is

xs 1

and, for all j=m+1, ,n, js. xj=0

Theorem 1 (Inner Product Rule)

z new ci bi ais c s

m

i 1

m

Relative cost,

z z new z c s ci ais (inner product rule)

i 1

More: (1) In a minimization problem, a basic feasible solution is optimal

if the relative costs of its all nonbasic variable are all positive or zero.

(2) One should choose an adjacent basic solution from which the relative

cost is the minimum.

Corollary: The alternate optima exists if z=0.

Theorem 2: (The Minimum Ratio Rule )

Given a nonbasic variable xs is change into

the basic variable set, then one of the basic

variable xr should leave from the basic

variable set, such that:

bi

max x s min ,

ais 0 a

is

i

The above minimum happens at i=r.

Corollary: The above rule fails if there exist unbounded optima.

Example: The LP Problem

max 6 x1 10x2 9 x3 20x4

x

s.t.4 x1 9 x2 7 x3 10x4 600

x1 x2 3 x3 8 x4 420

30x1 40x2 20x3 10x4 800

The Standard Form

max f 6 x1 10x2 9 x3 20x4

s.t.g1 4 x1 9 x2 7 x3 10x4 x5 600

g 2 x1 x2 3 x3 8 x4 x6 420

g 3 30x1 40x2 20x3 10x4 x7 800

Table 1(s=4,r=6,rc=2)

Basic={5 6 7};Nonbasic={1 2 3 4}

6

10

9

20

0

0

0

CB

Basis

x1

x2

x3

x4

x5

x6

x7

constraints

0

x5

4

9

7

10

1

0

0

600 (600/10=60)

0

x6

1

1

3

8

0

1

0

420(420/8=52.5)

0

x7

30

40

20

10

0

0

1

800(800/10=80)

6

10

9

20

-

-

-

Z=0

Z

Table 2(s=2,r=7,rc=3)

Basic={5 4 7};Nonbasic={1 2 3 6}

6

10

9

20

0

0

0

CB

Basis

x1

x2

x3

x4

x5

x6

x7

constraints

0

x5

2.75

7.75

3.25

0

1

-1.25

0

75(75/7.75=

9.6774)

20

x4

0.125

0.125

0.375

1

0

0.125

0

52.5(52.5/0.125=4

20)

0

x7

28.75

38.75

16.25

0

0

-1.25

1

275(275/38.75=

7.0798)

3.5

7.5

1.5

-

-

-2.5

-

Z=1050

Z

Table 3

Basic={5 4 2};Nonbasic={1 7 3 6}

6

10

9

20

0

0

0

CB

Basis

x1

x2

x3

x4

x5

x6

x7

constraints

0

x5

-3

0

0

0

1

-1

-0.2

20

20

x4

0.0323

0

0.3226

1

0

0.129

-0.0032

51.6129

10

x2

0.7419

1

0.4194

0

0

-0.0323

0.0258

7.0968

-2.0645

-

-0.1935

-

-

-1.6452

-2.2581

Z=1103.226

Z

2. The Two Phase Simplex MethodExample

min 3 x1 x2 x3

s.t.x1 2 x2 x3 11

4 x1 x2 3 x3 3

2 x1 x3 1

x1 , x2 , x3 0

The Standard Form

min 3 x1 x2 x3

s.t. x1 2 x2 x3 x4 11

4 x1 x2 2 x3 x5 3

2 x1 x3 1

x1 , x2 , x3 , x4 , x5 0

Two Phase Approach-Phase I

min x6 x7

s.t.x1 2 x2 x3 x4 11

4 x1 x2 2 x3 x5 x6 3

2 x1 x3 x7 1

Two Phase Approach-Phase I

Table 1

0

0

0

0

0

1

1

CB

Basis

x1

x2

x3

x4

x5

x6

x7

constraints

0

x4

1

-2

1

1

0

0

0

11(11/1=11)

1

x6

-4

1

2

0

-1

1

0

3(3/2=1.5)

1

x7

-2

0

1

0

0

0

1

1(1/1=1)

6

-1

-3

-

1

-

-

Z=4

Z

Two Phase Approach-Phase I

Final

0

0

0

0

0

1

1

CB

Basis

x1

x2

x3

x4

x5

x6

x7

constraints

0

x4

3

0

0

1

-2

2

-5

12

0

x2

0

1

0

0

-1

1

-2

1

0

x3

-2

0

1

0

0

0

-1

1

-

-

-

-

-

-

-

Z=0

Z

Two Phase Approach-Phase II

Table 1

-3

1

1

0

0

CB

Basis

x1

x2

x3

x4

x5

constraints

0

x4

3

0

0

1

-2

12(12/3=4)

1

x2

0

1

0

0

-1

1(1/0=)

1

x3

-2

0

1

0

0

1(1/-2<0)

-1

-

-

-

5

Z=2

Z

Two Phase Approach-Phase II

Final

-3

1

1

0

0

CB

Basis

x1

x2

x3

x4

x5

constraints

-3

x1

1

0

0

0.3333

-0.667

4

1

x2

0

1

0

0

-1

1

1

x3

0

0

1

0.6667

-1.333

9

-

-

-

-

-

Z=-2

Z

Example: Multi-Products

Manufacturing

A company manufactures three products: A, B, and

C. Each unit of product A requires 1 hr of

engineering service, 10 hr of direct labor, and 3lb of

material. To produce one unit of product B requires

2hr of engineering, 4hr of direct labor, and 2lb of

material. In case of product C, it requires 1hr of

engineering, 5hr of direct labor, and 1lb of material.

There are 100 hr of engineering, 700 hr of labor, and

400 lb of material available. Since the company

offers discounts for bulk purchases, the profit figures

are as shown in the next slide:

Example- Continued

Product A

Product B

Product C

Sales units

Unit profit

variable

s

Sales units

Unit profit

variables

Sales units

Unit profit

variables

0-40

10

X1

0-50

6

X5

0-100

5

X8

40-100

9

X2

50-100

4

X6

Over 100

4

X9

100-150

8

X3

Over 100

3

X7

Over 150

7

X4

Formulate a linear program to determine the most profitable product mix.

Problem Formulation

Let’s denote the variables as shown in the table, then

we have the following:

max 10X 1 9 X 2 8 X 3 7 X 4 6 X 5 4 X 6 3 X 7 5 X 8 4 X 9

X 1 ,, X 10

s.t.1( X 1 X 2 X 3 X 4 ) 2( X 5 X 6 X 7 ) 1( X 8 X 9 ) 100

10( X 1 X 2 X 3 X 4 ) 4( X 5 X 6 X 7 ) 5( X 8 X 9 ) 700

3( X 1 X 2 X 3 X 4 ) 2( X 5 X 6 X 7 ) 1( X 8 X 9 ) 400

0 X 1 40

0 X 2 60

X9 0

MATLAB PROGRAM

f=[-10 -9 -8 -7 -6 -4 -3 -5 -4]';

A=[1 1 1 1 2 2 2 1 1; 10 10 10 10 4 4 4 5 5;3 3 3 3 2

2 2 1 1];

b=[100;700;400];

Aeq=[];beq=[];

LB=[0 0 0 0 0 0 0 0 0];

UB=[40 60 50 Inf 50 50 Inf 100 Inf];

[X,FVAL,EXITFLAG,OUTPUT,LAMBDA]=LINPROG(

f,A,b,Aeq,beq,LB,UB)

Solution

X’= 40.0000 22.5000

0.0000

FVAL =-715.0000

EXITFLAG =1

OUTPUT =

iterations: 7

cgiterations: 0

algorithm: 'lipsol'

LAMBDA =

ineqlin: [3x1 double]

eqlin: [0x1 double]

upper: [9x1 double]

lower: [9x1 double]

0.0000

0.0000 18.7500

0.0000

0.0000

0.0000

3. Sensitivity Analysis

Shadow Prices: To evaluate net impact in

the maximum profit if additional units of

certain resources can be obtained.

Opportunity Costs: To measure the negative

impact of producing some products that are

zero at the optimum.

The range on the objective function

coefficients and the range on the RHS row.

Example

A factory manufactures three products, which

require three resources – labor, materials

and administration. The unit profits on these

products are $10, $6 and $4 respectively.

There are 100 hr of labor, 600 lb of material,

and 300hr of administration available per day.

In order to determine the optimal product mix,

the following LP model is formulated and

solve:

Basic LP Problem

max Z 10x1 6 x2 4 x3

s.t.x1 x2 x3 100 (labor)

10x1 4 x2 5 x3 600 (mat erial)

2 x1 2 x2 6 x3 300 (administration)

x1 , x2 , x3 0

Optimal Solution and Sensitivity

Analysis

x1=33.33, x2=66.67,x3=0,Z=733.33

Shadow prices for row 1=3.33, row 2=0.67,

row 3=0

Opportunity Costs for x3=2.67

Ranges on the objective function coefficients:

6≦c1(10)≦15, 4≦c2(6)≦10,

-∞≦c3(4)≦6.67

Optimal Solution and Sensitivity

Analysis- Continued

60≦b1(100)≦150, 400≦b2(600)≦1000,

200≦b3(300)≦∞

100% Rules

100% rule for objective function coefficients

c j

c

j

100%

j

100% rule for RHS constants

b j

b

j

j

100%

Examples

Unit profit on product 1 decrease by $1, but increases by $1

for products 2 and 3, will the optimum change?(δc1=-1, Δc1=4, δc2=1, Δc2=4, δc3=1, Δc3=2.67)

1 1

1

0.875 1

4 4 2.67

Simultaneous variation of 10 hr decrease on labor 100 lb

increase in material and 50hr decrease on administration

10 100 50

1

40 400 100