MREA_2BPDR_9-1.0 - University of Michigan

advertisement

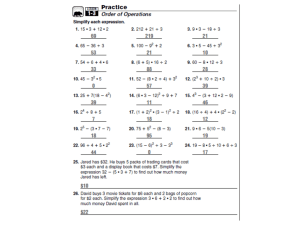

Preliminary Design Review (PDR) The University Of Michigan 2011 1 Vehicle: i. 2 Vehicle: ii. Nose Main Chute Separation Bay Main Chute Separation 3 Vehicle: iii. Main Chute Seperation Aviation Bay Aviation Bay Access Cut Apogee Separation Bay Apogee Separation 4 Vehicle: iv. Apogee Separation Apogee Separation Bay Motor 5 Vehicle Dimensions Body Tube ◦ 5.5 in dia. Can ◦ 2.0 in dia. 6 Launch Vehicle Verification Vehicle/Payload design justification Static stability analysis Materials/system justification (discussed in further detail in proceeding slides) 7 Vehicle Design Justification Different ideas for reducing drag Requirements ◦ ◦ ◦ ◦ ◦ Stable Fast Precise Consistent Highly variable 8 Vehicle Materials Nosecone Body Cans Fins Polystyrene Plastic Blue Tube (Apogee Comp.) Blue Tube (Apogee Comp.) G10 fiberglass 9 Material Justifications Phenolic Tubing ◦ Cured paper fibers ◦ Cheapest, strong, brittle Blue Tube 2.0 ◦ High-density paper ◦ More expensive, durable, dense Carbon Fiber ◦ Strands of woven carbon ◦ Most expensive, strongest, labor-intensive 10 Static Stability Margin 1.5 in neutral configuration pre-launch 2.4 after engine burnout ◦ Drag mechanism actuated RockSim estimated CP/CG locations On the unstable side Add mass to nose of rocket 11 Recovery Scheme Two Separations ◦ Apogee Drogueless ◦ 500 Feet Main Parachute Double Redundancy ◦ Flight computer ◦ Altimeter 500 Feet Apogee 12 Vehicle Safety Verification Plan This matrix shows detrimental failures in red, recoverable failures in yellow, and failures with a minimal effect in green 13 Testing Plans Ground test proper body tube separation during E-Charge ignition Use a multimeter to measure the current the Flight Computer sends to each ECharge during ground simulations Servo selection through torque testing on flap from collected simulation/wind tunnel data 14 Motor Selection Motor Manufacturer: Loki Motor Designation:L1482-SM Total Impulse: 868.7 lb-s Mass pre/post burn: Pre:7.8 lb Post:3.8 lb 15 Thrust-To-Weight Ratio 16 Rail Exit Velocity Rail Exit Velocity: 85.1 ft/s Rail Length: 10 ft 17 Recovery Avionics Raven Flight Computer Competition Altimeter 4 Total E-Charges 2 from Flight Computer 2 from Altimeter 1 ◦ 1 1 ◦ 1 Main Apogee Charge @ 5280 feet Backup Main Chute Charge @ 400 feet Backup Apogee TB 9V Batteries AvBay Flight Computer Competition Altimeter Positive TB Main Chute TB 18 Aerodynamics-Linear Flaps: i. Flap Geometry 0% closed corresponds to the position where the flap is not exposed to air flow 100% closed corresponds to where the flap is fully extended into the flow Flap Max % Closed A 100 Flap End Geometry Semi-Circle Can Inner Dia [in] 1.504 Flap Width [in] B 100 Semi-Circle 2.551 2.551 C 65 Rectangular 2.551 2.551 D 75 Rectangular 2.551 2.051 1.504 19 Aerodynamics-Linear Flaps: ii. Flap A Flap B 20 Aerodynamics-Linear Flaps: iii. Flap C Flap D 21 Aerodynamics-Linear Flaps: iv. Drag data from cases run at 300 m/s Flap A B C D Maximum Drag [N] 81.7235 240.396 204.086 197.838 *NOTE: All flap data is for one flap and all rocket data is for half-body 22 Aerodynamics-Rotating Flaps: i. Moment Concerns with the y component of the force generated by the flap at various angles Analyzed at the most extreme case (largest can and flap size at 45 ̊) Force in the y direction caused by the flap angle deflection is negated by the force it creates on the wall of the can Component Rocket Force in y-direction [N] -199.8 Flap 199.61 *NOTE: All data is from a simulated wind speed of 300 m/s 23 Aerodynamics-Rotating Flaps: ii. ANSYS Fluent CFD mesh sizes were refined in areas of interest such as the flap and the interior wall for optimal results. 24 Structures-Can Analysis Analyzed the worst case scenario (flaps 100% closed) Pressure forces in front of the valve are not a concern Low pressure pockets behind the valve are not a concern 25 Controls: i. Proportional Integral Derivative (PID) controller that will induce pressure drag as a means of regulating vehicle altitude Drag is calculated dynamically during flight Controller should respond to physical system changes in no more than 50 milliseconds and recover within 2% of the goal altitude 26 Controls-System Model: ii. Dynamic Apogee-Rectifying Targeting (DART) Control System Dynamic Target: Used to aid in assuring the mean energy path solution is followed Restrained Controller: Proportional Integral Derivative (PID) derived controller with physical limits Physics Plant: Simulation of vehicle-environment interaction given controller commands Instrument Uncertainty: Propagation of instrument uncertainty into system values Alt. Projection: Projection of rocket apogee altitude with same physics plant model for consistency 27 Controls – Dynamic Target Controls – Restrained Controller Controls - Physics Controls –Instrument Uncertainty Controls – Apogee Calculation Flight Avionics Drag Servo Competition Altimeter Drag Computer Drag Servo 9V Batteries Drag Computer Competition Altimeter 33 Propulsion Select a motor such that it will allow our rocket to exceed one mile in our minimum drag configuration 34 Payload Design Drag Control System Actuating flaps located within side cans to control drag Control system will activate under specific altitude and/or velocity conditions 35 Payload Test Plan i. Flap Drag Testing Simulations/flow characterization using compressible flow in ANSYS Fluent CFD over a range of Mach numbers Test drag flap mechanism in various configurations to confirm results from simulated model Produce a function for control system relative to drag, flow speed and flap deflection 36 Payload Test Plan ii. Drag Flap Control System Testing 4 constants to vary (Kp, Ki, Kd, Dt) N^4 simulations for N possible different constants Parallel processing in Matlab to tackle Monte Carlo simulation NYX / FLUX supercomputers from UM Center for Advance Computing used to tune constants for best performance 37