Lecture 8 * Viscoelasticity and Deformation

advertisement

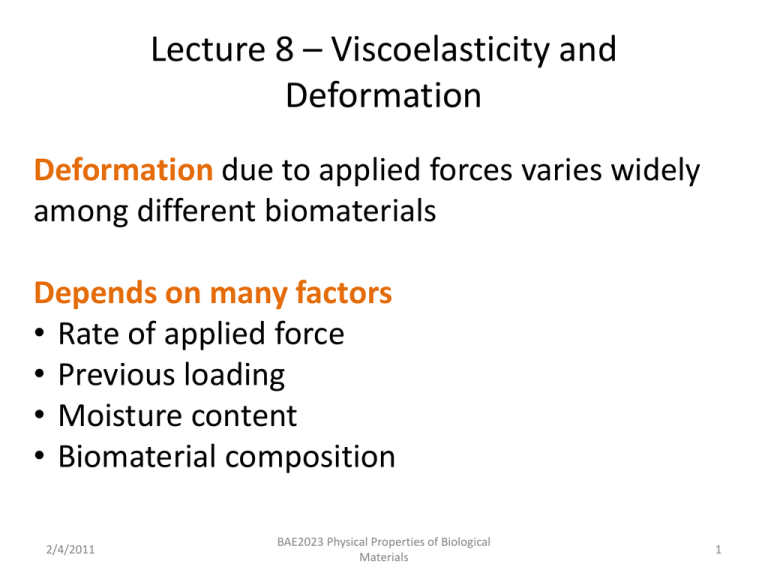

Lecture 8 – Viscoelasticity and Deformation Deformation due to applied forces varies widely among different biomaterials Depends on many factors • Rate of applied force • Previous loading • Moisture content • Biomaterial composition 2/4/2011 BAE2023 Physical Properties of Biological Materials 1 Lecture 8 – Viscoelasticity and Deformation Normal stress: Force per unit area applied perpendicular to the plane Normal strain: Change in length per unit of length in the direction of the applied normal stress 2/4/2011 BAE2023 Physical Properties of Biological Materials 2 Lecture 8 – Viscoelasticity and Deformation Modulus of elasticity Linear region of stress strain curve E = σ/ε For biomaterials: apparent E = σ/ε at any given point (secant method) Tangent method: slope of stress/strain curve at any point 2/4/2011 BAE2023 Physical Properties of Biological Materials 3 Lecture 8 – Viscoelasticity and Deformation Poisson’s Ratio, μ • When a material is compressed in one direction, it usually tends to expand in the other two directions perpendicular to the direction of compression • The Poisson ratio is the ratio of the fraction (or percent) of expansion divided by the fraction (or percent) of compression, for small values of these changes. 2/4/2011 BAE2023 Physical Properties of Biological Materials 4 Poisson’s Ratio • Ratio of the strain in the direction perpendicular to the applied force to the strain in the direction of the applied force. • For uniaxial compression in Z direction: εz = σz/E εy = -μ·εz εx = -μ·εz 2/4/2011 BAE2023 Physical Properties of Biological Materials 5 Poisson’s Ratio Multi-axial Compression See equations in 4.2 page 117 Maximum Poisson’s = 0.5 for incompressible materials to 0.0 for easily compressed materials Examples: • Gelatin gel – 0.50 • Soft rubber – 0.49 • Cork – 0.0 • Potato flesh – 0.45 – 0.49 • Apple flesh - 0.21 – 0.29 • Wood – 0.3 to 0.5 More porous means smaller Poisson’s Ratio 2/4/2011 BAE2023 Physical Properties of Biological Materials 6 Lecture 8 – Viscoelasticity and Deformation Shearing Stresses Shear Stress: Force per unit area acting in the direction parallel to the surface of the plane, τ Shear Strain: Change in the angle formed between two planes that are orthogonal prior to deformation that results from application of sheer stress, γ 2/4/2011 BAE2023 Physical Properties of Biological Materials 7 Lecture 8 – Viscoelasticity and Deformation Shear Modulus: Ratio of shear stress to shear strain G = τ/γ Measured with parallel plate shear test (pg. 119) 2/4/2011 BAE2023 Physical Properties of Biological Materials 8 Lecture 8 – Viscoelasticity and Deformation Example Problem The bottom surface (8 cm x 12 cm) of a rectangular block of cheese (8 cm wide, 12 cm long, 3 cm thick) is clamped in a cheese grater. • The grating mechanism moving across the top surface of the cheese applies a lateral force of 20N. • The shear modulus, G, of the cheese is 3.7kPa. • Assuming the grater applies the force uniformly to the upper surface, estimate the lateral movement of the upper surface w/respect to the lower surface 2/4/2011 BAE2023 Physical Properties of Biological Materials 9 Lecture 8 – Viscoelasticity and Deformation Stresses and Strains: Described as Deviatoric or Dilitational Dilitational: Causes change in volume Deviatoric: Causes change in shape but negligible changes in volume Bulk Modulus, K: describes response of solid to dilitational stresses 2/4/2011 BAE2023 Physical Properties of Biological Materials 10 Lecture 8 – Viscoelasticity and Deformation Dilatation: (Vf – V0)/V0 Δ V = Vf – V 0 K = ΔP/(Δ V / V0) ΔP = Average normal stress, uniform hydrostatic gauge pressure K = average normal stress/dilatation V is negative, so K is negative •Example of importance: K (Soybean oil) > K (diesel) •Will effect the timing in an engine burning biodiesel 2/4/2011 BAE2023 Physical Properties of Biological Materials 11 Lecture 8 – Viscoelasticity and Deformation Apples compress easier than potatoes so they have a smaller bulk modulus, K (pg. 120) but larger bulk compressibility -1 K =bulk compressibility Strain Energy Density: Area under the loading curve of stress-strain diagram • Sharp drop in curve = failure 2/4/2011 BAE2023 Physical Properties of Biological Materials 12 Stress strain curve for uniaxial compression of cylindrical sample of food product 2/4/2011 BAE2023 Physical Properties of Biological Materials 13 Lecture 8 – Viscoelasticity and Deformation Stress-Strain Diagram, pg. 122 Toughness: Area under curve until it fails Bio yield point: Failure point Resilience: Area under the unloading curve • Resilient materials “spring back”…all energy is recovered upon unloading Hysteresis: strain density – resilience Figure 4.6, page 124 Figure 4.7, page 125 2/4/2011 BAE2023 Physical Properties of Biological Materials 14 Lecture 8 – Viscoelasticity and Deformation Factors Affecting Force-Deformation Behavior • Moisture Content, Fig. 4.6b • Water Potential, Fig. 4.8 • Strain Rate: More stress required for higher strain rate, Fig. 4.8 • Repeated Loading, Fig. 4.9 2/4/2011 BAE2023 Physical Properties of Biological Materials 15 Effect of water potential and strain rate on stressstrain curve of cylindrical Ida Red apple tissue 2/4/2011 BAE2023 Physical Properties of Biological Materials 16 Lecture 8 – Viscoelasticity and Deformation Stress Relaxation: Figure 4.10 pg 129 Material is deformed to a fixed strain and strain is held constant…stress required to hold strain constant decreases with time. 2/4/2011 BAE2023 Physical Properties of Biological Materials 17 Lecture 8 – Viscoelasticity and Deformation Creep: Figure 4.11 pg. 130 A continual increase in deformation (strain) with time with constant load 2/4/2011 BAE2023 Physical Properties of Biological Materials 18 Lecture 8 – Viscoelasticity and Deformation Tensile Testing • Not as common as compression testing • Harder to do See figure 4.12 page 132 2/4/2011 BAE2023 Physical Properties of Biological Materials 19 Lecture 8 – Viscoelasticity and Deformation Bending E=modulus of elasticity D=deflection F=force I = moment of inertia E=L3(48DI)-1 I=bh3/12 2/4/2011 BAE2023 Physical Properties of Biological Materials 20 Lecture 8 – Viscoelasticity and Deformation Bending • Can be used for testing critical tensile stress at failure • Max tensile stress occurs at bottom surface of beam σmax=3FL/(2bh2) 2/4/2011 BAE2023 Physical Properties of Biological Materials 21 Lecture 8 – Viscoelasticity and Deformation Contact Stresses (handout from Mohsenin book) Hertz Problem of Contact Stresses Importance: “In ag. products the Hertz method can be used to determine the contact forces and displacements of individual units” 2/4/2011 BAE2023 Physical Properties of Biological Materials 22 Lecture 8 – Viscoelasticity and Deformation Contact Stresses Assumptions: • Material is homogeneous • Loads applied are static • Hooke’s law holds • Contacting stresses vanish at the opposite ends • Radii of curvature of contacting solid are very large • compared to radius of contact surface • Contact surface is smooth 2/4/2011 BAE2023 Physical Properties of Biological Materials 23 Lecture 8 – Viscoelasticity and Deformation Contact Stresses 𝑆𝑚𝑎𝑥 = 3 𝐹 2 Π𝑎𝑏 Maximum contact stress occurs at the center of the surface of contact a and b are the major and minor semi axes the elliptic contact area For ag. Products, consider bottom 2 figures in Figure 6.1 2/4/2011 BAE2023 Physical Properties of Biological Materials 24 Lecture 8 – Viscoelasticity and Deformation 2/4/2011 BAE2023 Physical Properties of Biological Materials 25 Lecture 8 – Viscoelasticity and Deformation 2/4/2011 BAE2023 Physical Properties of Biological Materials 26 Lecture 8 – Viscoelasticity and Deformation 2/4/2011 BAE2023 Physical Properties of Biological Materials 27 HW Assignment Due 2/11 Problem 1: An apple is cut in a cylindrical shape 28.7 mm in diameter and 22.3 mm in height. Using an Instron Universal Testing Machine, the apple cylinder is compressed. The travel distance of the compression head of the Instron is 3.9 mm. The load cell records a force of 425.5 N. Calculate the stress εz , and strain σz on the apple cylinder. 2/4/2011 BAE2023 Physical Properties of Biological Materials 28 HW Assignment Due 2/11 Problem 2: A sample of freshly harvested miscanthus is shaped into a beam with a square cross section of 6.1 mm by 6.1 mm. Two supports placed 0.7 mm apart support the miscanthus sample and a load is applied halfway between the support points in order to test the Force required to fracture the sample. If ultimate tensile strength is 890 MPa, what would be the force F (newtons) required to cause this sample to fail? 2/4/2011 BAE2023 Physical Properties of Biological Materials 29 HW Assignment Due 2/11 Problem 3: Ham is to be sliced for a deli tray. A prepared block of the ham has a bottom surface of 10 cm x 7 cm. The block is held securely in a meat slicing machine. A slicing blade moves across the top surface of the ham with a uniform lateral force of 27 N and slices a thin portion of meat from the block. The shear modulus, G, of the ham is 32.3 kPa. Estimate the deflection of the top surface with respect to the bottom surface of the block during slicing. 2/4/2011 BAE2023 Physical Properties of Biological Materials 30 HW Assignment Due 2/11 Problem 4: •Sam, the strawberry producer, has had complaints from the produce company that his strawberries are damaged during transit. Sam would like to know the force required to damage the strawberries if they are stacked three deep in their container. •The damage occurs on the bottom layer at the interface with the parallel surface of the container and also at the point of contact between the layers of strawberries. •An hydrostatic bulk compression test on a sample of Sam’s strawberries indicates an average bulk modulus of 225 psi. Testing of specimens from Sam’s strawberry crop shows a compression modulus E of 200 psi. The average strawberry diameter is 1.25 inches and the axial deformation due to the damage in transit averages 0.23 inches. The modulus of elasticity for Sam’s variety of strawberries is reported to be 130 psi. •Estimate the force Sam’s strawberries may be encountering during transit. (Hertz method) 2/4/2011 BAE2023 Physical Properties of Biological Materials 31