MicroProp MIG2

advertisement

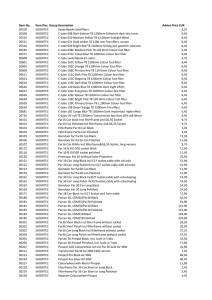

MICROPROP DC2 - EDUCATION Microprop AB AGENDA 140312 9.00-10.00 10.15 -12.00 12-13 13.00 -16.00 16.00 -17.00 Presentation Microprop DC2 Assembly and calibration Lunch Fault finding Conclusion and CE-marking PRESENTATION - Basic functions of a tiltrotator and assembling SS10. Principle function of the system Microconf DC2 Machine safety Equipment options Calibration of the system Remote support CE-documentation MICROPROP DC2 – PREREQUISITES SS10 - Servo assisted line (hammer line) (i.e. not an mechanical link) - That line must work at the digging movement. MICROPROP DC2 – HYDRAULIC PREREQUSITES -The pressure should be about 225 bar -The flow should be about: EC: 02 05A/B 10 15 20 30 l/min 40 40/50 70 90 120 130 TILTROTATOR SS10 SS10 OR SS9 Benefits of SS10 vs SS9 - Simultaneous operation of tilt, rotation and extra. - Smoother operation with SS10 - Works on older machines MICROPROP DC2 – WHAT IS IT? - Powerful and simple. - Tiltrotator control - Track control - Wheel steering - Extra hydraulic functions - Remote support via Microconf and smart phone (Android) - Use of smart phone as display. - Machine adaptations - Conforms to the machine directive MICROPROP DC2 – THE SYSTEM MICROPROP DC2 – CABIN MODULE Analog inputs - 6 rollers Digital inputs - 6 switches for joysticks Outputs - 6 analog outputs - 2 extra onoff for versatlie functions. MICROPROP DC2 – TILTROTATOR MODULE In cables: - 4 double analog outputs (A/B) - 1 digital output for quick hitch MACHINE SAFETY MACHINE SAFETY– THE SYSTEM FULLFILS EN 13849-1 1. A single fault must never cause a dangerous situation. 2. When controllers are released the machine must stop. This means: - A ON/OFF function that is control with a switch requires switching function of the switch (Note: shift function may be used without the double signals.) MACHINE SAFETY – MONITORING OF DIGITAL FUNCTIONS 24V DI MACHINE SAFETY – MONITORING OF DIGITAL FUNCTIONS 24V DI MACHINE SAFETY – MONITORING OF DIGITAL FUNCTIONS 24V DI DI MACHINE SAFETY– THE SYSTEM FULLFILS EN 13849-1 1. A single fault must never cause a dangerous situation. 2. When controllers are released the machine must stop. This means: - A ON/OFF function that is control with a switch requires switching function of the switch (Note: shift function may be used without the double signals.) - A analog function requires crossed signals MACHINE SAFETY – MONITORING OF ANALOG FUNCTIONS 5V GND AI1 MACHINE SAFETY – MONITORING OF ANALOG FUNCTIONS 5V GND AI1 AI2 MACHINE SAFETY– THE SYSTEM FULLFILS EN 13849-1 1. A single fault must never cause a dangerous situation. 2. When controllers are released the machine must stop. This means: - A ON/OFF function that is control with a switch requires switching function of the switch (Note: shift function may be used without the double signals.) - A analog function requires crossed signals - A hydraulic function that may be a risks for the surroundings requires two separate controls of which at least one must be monitored. MACHINE SAFETY – MONITORING OF HYDRAULICS Control system CV CVP HYDRAULICS Safety block Double feeder Track control Single feeder MACHINE SAFETY– MONITORING HYDRAULICS SINGLE FEEDER MACHINE SAFETY– MONITORING PWM SIGNALS Hyttmodul Processor ECU MACHINE SAFETY– MONITORING PWM SIGNALS Hyttmodul Processor ECU MACHINE SAFETY– MONITORING PWM SIGNALS Hyttmodul Processor ECU MICROPROP DC2 – EQUIPMENT OPTIONS The system has 6 analog outputs from the cabin module. - Single feeder - Double feeder - PWM signal feeder - Track control - Wheel steering - Other hydraulic controls MICROPROP DC2 – SINGLE FEEDER OR DOUBLE FEEDER Double feeder is used to be able to use the auxiliary outputs of the machine two-ways. If the machine auxiliary outputs are connected to tank (one-way) this needs to be changed to two-way function. MICROPROP DC2 – SINGLE FEEDER OR DOUBLE FEEDER MICROPROP DC2 – SINGLE FEEDER OR DOUBLE FEEDER Double feeder is used to be able to use the auxiliary outputs of the machine two-ways. If the machine auxiliary outputs are connected to tank (one-way) this needs to be changed to two-way function. - Single feeder should be used when: - the tiltrotator is directly mounted. there is a quick hitch on the machine and the driver accepts using a pedal for auxiliary outputs. - Double feeder should be used if: - There is a quick hitch and the driver wants to use a roller for auxiliary outputs. There is a quick hitch and the original aux control was with rollers in the original joysticks. The tiltrotator is directly mounted but the driver wants to remove the tiltrotator some times and the original aux control was with rollers in the original joysticks. MICROPROP DC2 – JOYSTICK EMULATION Can be used when the machine is equipped with machine original proportional controlled hydraulics. • • • • No hydraulic assembly (under certain prerequisites.) Is connected directly to the machine joystick inputs. The system can “control” one or two original rollers. Simpler and cheaper installation and any tooling program in the machine is still intact. MICROPROP DC2 – JOYSTICK EMULATION Digital (Cat) Analog (Doosan, komatsu…) MICROPROP DC2 – JOYSTICKS Microprop MIG2 Only tiltrotator Minimal - 2 rollers - 5 + 5 free switches Standard - 2 + 1 rollers - 5 + 5 free switches Extra rulle - 4 rollers - 5 + 5 free switches Only tiltrotator with FNR Standard - 2 rollers - FNR (right joystick) - 5 + 4 free switches Extra roller - 2+1 rollers - FNR (right joystick) - 5 + 4 free switches 2 Extra rollers - 4 rollers - FNR (right joystick) - 5 + 4 free switches Microprop MIG1 Standard 8415xx - 2 rollers 3 Extra rollers - 3 + 2 rollers - FNR (right joystick) - 5 + 4 free switches Extra roller 8415xx - 3 rollers MICROPROP MIG1 - Equippable with 2 rollers MICROPROP MIG2 - Equippable with 3 rollers and 7 switches (FNR as an option) - Flexible and ergonomical hand support. - Patented. MICROPROP MIG2 MICROPROP MIG2 – HAND SUPPORT - Fits all sizes of hands - Integrated in handle CALIBRATION AND CHANGES OF THE CONTROL SYSTEM REMOTE SUPPORT All settings in the system are avaliable (some restrictions of program updates apply). From PC to PC - Can be used to help a technician at a work shop or in the field (obs internet needed). - Remote education in the PC-program - There is a Microconf Remote version that only has remote options From PC to mobile phone - To help a customer in the field. MOBILE APP (ANDROID) What can you do? - Change users. - Calibrate joysticks. - Connect to remote support - Create and change tools in tooling program. MENU SYSTEM IN CABIN MODULE What can you do? - Change user. - Calibrate joysticks. - Make backups of settings from tiltmodule or from cabin module. (This is also done automatically) - Change already created tools in tooling program. - Change direction of functions. TOOLING PROGRAM Makes setting of speeds possible for the end user without changing the fitters’ settings. - Up to 20 different tool settings. - Each tool starts from the fitters’ settings and uses a %. - The customer can do changes themselves: • • • With the mobile application (create and change) With PC (microconf lite) (create and change) With the menu in the cabin module (only change) - Factory settings are always selectable: ”NO TOOL”. CALIBRATION WITH MICROCONF - EXCERCISES • • • • • • • Connection with USB , Bluetooth Choose tiltrotator model Calibration of rollers Input mapping. Current settings (tiltrotator, feeder) Wizard Ramps MICROPROP DC2 – DOCUMENTING YOUR DELIVERY HOW ABOUT THE CE MARKING OF THE MACHINE? - The organization/company that puts the machine on the market is responsible to make sure that the machine still is in compliance with the CE-marking. - The goal is to make the machine’s CE-mark as good as it was before the add-on/change. - Microprop/engcon will provide the means to be as good as the manufacturer in terms of user manual and labeling of the machine. - The responsible for the installation is the fitters’ but by following our instructions the fitter should feel comfortable that there is no surprises down the line. HOW TO BE AS GOOD AS THE CE MARK FROM THE MANUFACTURER - Make sure the supplier of the control system (i.e. Microprop) has attached the “Declaration of incorporation” to the assembly instruction. - Follow the attached assembly instruction very strictly. - Attach labels into the machine that shows the machine functions if the joysticks are changed. - Make the same changes to the user manual of the control system. - Make sure the user manual of the machine does not have contradictory information after the change of the machine (i.e. change of joysticks) - Make a functional check of the machine and make sure that the user manuals are now a correct reflection of how it actually works. - Document the installation. Take pictures, note the revision and document number of the assembly instructions, note the machine id and serial number etc. THE MICROPROP DELIVERY – HOW MICROPROP WILL HELP - “Declaration of incorporation” mention the correct standards as interpretation to the machine directive. - Assembly instructions and user manuals with an unique document number and version number. - Labels to stick to the windows of the machine. - Stickers to build your own label. News: - Stickers to add to the machine user manual on the pages/places where the Microprop installation has made the information obsolete. - A machine card where you can note all necessary information about the installation. This should be stored at the fitter. THANK YOU! Fill in the participants