PID Controllers - University of Toledo

advertisement

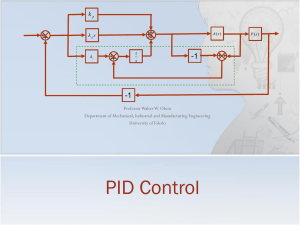

Professor Walter W. Olson Department of Mechanical, Industrial and Manufacturing Engineering University of Toledo PID Control Outline of Today’s Lecture Review Margins from Nyquist Plots Margins from Bode Plot Non Minimum Phase Systems Ideal PID Controller Proportional Control Proportional-Integral Control Proportional-Integral Derivative Control Ziegler Nichols Tuning Margins Margins are the range from the current system design to the edge of instability. We will determine Gain Margin How much can gain be increased? Formally: the smallest multiple amount the gain can be increased before the closed loop response is unstable. If the gain margin is expressed in dB, then the multiple gain is G 100.05gm Phase Margin How much further can the phase be shifted? Formally: the smallest amount the phase can be increased before the closed loop response is unstable. Stability Margin How far is the the system from the critical point? Gain and Phase Margin Definition Nyquist Plot 1 gm -1 m Magnitude, dB Gain and Phase Margin Definition Bode Plots 0 Positive Gain Margin Phase, deg w -180 Phase Margin w Phase Crossover Frequency Stability Margin It is possible for a system to have relatively large gain and phase margins, yet be relatively unstable. Stability margin, sm Non-Minimum Phase Systems Non minimum phase systems are those systems which have poles on the right hand side of the plane: they have positive real parts. This terminology comes from a phase shift with sinusoidal inputs s 1 s 1 G ( s ) and G 2 Consider the transfer functions 1 s s 2 s( s 2) The magnitude plots of a Bode diagram are exactly the same but the phase has a major difference: Another Non Minimum Phase System A Delay Delays are modeled by the function which multiplies the T.F. y (t ) x (t T ) G( s) eTs Proportional-Integral-Derivative Controller Based on a survey of over eleven thousand controllers in the refining, chemicals and pulp and paper industries, 97% of regulatory controllers utilize PID feedback. L. Desborough and R. Miller, 2002 [DM02]. PID Control, originally developed in 1890’s in the form of motor governors, which were manually adjusted The first theory of PID Control was published by a Russian (Minorsky) who was working for the US Navy in 1922 The first papers regarding tuning appeared in the early 1940’s Today. there are several hundred different rules for tuning PID controllers (See Dwyer, 2003, who has cataloged the major methods) While most of the discussion is about the “ideal” PID controller, there are many forms of the PID controller PID Control Advantages Process independent The best controller where the specifics of the process can not be modeled Leads to a “reasonable” solution when tuned for most situations Inexpensive: Most of the modern controllers are PID Can be tuned without a great amount of experience required Disadvantages Not optimal for the problems Can be unstable unless tuned properly Not dependent on the process Hunting (oscillation about an operating point) Derivative noise amplification The Ideal PID Controller The input/output realtionship for the PID Controller is the Integral-Differential Equation dy 1 u(t ) k p y (t ) kt y ( )d kd k p y (t ) 0 dt Ti The ideal PID controller has the transfer function t 0 t y ( )d Td ki 1 CPID ( s) k p kd s k p 1 Td s s Ti s Structurally it would look like CPID ( s) ++ kp ki s ++ + kd s -1 P( s) dy dt The Ideal PID Controller The system transfer function is G( s) CPID ( s) R(s) ++ Y ( s) C ( s ) P( s ) R( s ) 1 C ( s ) P( s ) kp ki s ++ + kd s -1 Y(s) P( s) Proportional Control Y ( s) k P( s ) d R( s ) 1 k d P ( s ) CPID ( s) kp Y(s) R(s) ++ ki s ++ + kd s -1 P( s) Proportional Control Monahemi, 1992, reports that the angel of attack, , to the elevator angle, , for an F-16 is 0.0072 s 23 s 0.05s 0.04 ( s) P( s ) ( s) s 0.7 s 1.7 s 2 0.08s 0.04 2 This system is unstable. Can it be stabilized with a proportional controller? Proportional Controller 0.0072 s 23 s 0.05s 0.04 ( s) P( s ) ( s ) s 0.7 s 1.7 s 2 0.08s 0.04 2 0.0072 s 23 s 2 0.05s 0.04 k p k p P( s ) Y ( s) G( s) R( s ) 1 k p P( s ) s 0.7 s 1.7 s 2 0.08s 0.04 0.0072 s 23 s 2 0.05s 0.04 k p kp=7.2 Proportional Controller With kp=7.2, } Error Also: the response time is poor We could reduce the error with a prefilter: CPID ( s) R(s) 0.139 ++ kp ki s ++ + kd s -1 Y(s)=(s) P( s) Proportional – Integral Controller Most controllers using this technology are of this form: ki k p P( s ) k p s ki P ( s ) Y ( s) s k R( s ) 1 k p s ki P ( s ) 1 k p i P( s ) s CPID ( s) kp Y(s) R(s) ++ ki s ++ + P( s) kd s -1 This reacts to the system error and reduces it Proportion-Integral Control Applying PI control to the F-16 Elevator, 0.0072 s 23 s 2 0.05s 0.04 k k p s ki 2 k p i P( s) s 0.7 s 1.7 s 0.08 s 0.04 Y ( s) s 2 k R( s) 0.0072 s 23 s 0.05s 0.04 1 k p i P( s) 1 k p s ki s 0.7 s 1.7 s 2 0.08s 0.04 s k p s s 0.7 s 1.7 s 2 0.08s 0.04 ki 0.0072 s 23 s 2 0.05s 0.04 Y ( s) R ( s ) 1 k p s s 0.7 s 1.7 s 2 0.08s 0.04 ki 0.0072 s 23 s 2 0.05s 0.04 with C ( s ) 100 k p 100 ki 50 50 s Response time improved with no error Proportional- Integral-Derivative Control The derivative component is rarely used. Reduces overshoot May slows the response time depending on the system Sensitive to noise For the F-16 Elevator with C ( s ) 250 650 25s s PID Tuning Tuning is the choosing of the parameters kd, ki, and kp, for a PID Controller The oldest and most used method of tuning are the ZieglerNichols (ZN) methods developed in the 1940’s. The first method is based on the assumption that the process without its feedback loop performs with a 1st order transfer function, perhaps with a transport delay The second method assumes that a higher order system has dominant poles which can be excited by gain to the point of steady oscillation In order to establish the constants for computing the parameters simple tests are performed of the process Ziegler-Nichols PID Tuning Method 1 for First Order Systems A system with a transfer function of the form P( s ) has the time response to a unit step input: K st0 e sa This response might also be generated from a higher order system that is has high damping. Ziegler-Nichols PID Tuning Method 1 for First Order Systems The advice given is to draw a line tangent to the response curve through the inflection point of the curve. However, a mathematical first order response doesn’t have a point of inflection as it is of the form y(t ) e at(at no place does the 2nd derivative change sign.) My advice: place the line tangent to the initial curve slope You also have to adjust for the gain K of the system by multiplying compensator by 1/K Rise Time T Lag L Type P PI PID kp T L 0.9T L 1.2T L Ti Td 3.33L 2L 0.5L Ziegler-Nichols PID Tuning Method 1 for First Order Systems For this example, Rise Time T Lag L L 0.1 T 0.2 1 CPI ( s ) k p 1 Ti s 0.9 2 1 CPI ( s ) 1 0.1 3.33Ls 1 CPI ( s ) 1.8(1 ) 0.333s Type P PI PID kp Ti 0.9T L 1.2T L 3.33L T L 2L Td 0.5L Ziegler-Nichols PID Tuning Method 2 for Unknown Oscillatory System The form of the transfer function unknown but the system can be put in steady oscillation by increasing the gain: Increase gain,K, on closed loop system until the gain at steady oscillation, Kcr, is found Then measure the critical period, Pcr Apply table for controller constants and multiply by system gain 1/K Type kp Ti Pcr P 0.5Kcr 1 Cycle PI 0.45Kcr Pcr 1.2 PID 0.6Kcr 0.5Pcr Td 0.125Pcr Ziegler-Nichols PID Tuning Method 2 Example k=1000 k=1500 k=2000 17.8 1.0 Pcr 2.8 sec 6 Type 1 Cycle Kcr=1875 1.0 17.8 kp Ti Td 0.5Kcr P Pcr k=1750 PI 0.45Kcr Pcr 1.2 PID 0.6Kcr 0.5Pcr 0.125Pcr 1.2 CPI ( s) 0.45*1875 1 2.8s 0.4286 CPI ( s) 843.75 1 s Ziegler-Nichols PID Tuning Method 2 Example 1.2 CPI ( s) 0.45*1875 1 2.8s 0.4286 CPI ( s) 843.75 1 s Pcr 1 Cycle Kcr=1875 1.0 17.8 Summary Ideal PID Controller Proportional Control Proportional-Integral Control Proportional-Integral Derivative Control Ziegler-Nichols Tuning Next Class: PID Controls Continued