19967042

advertisement

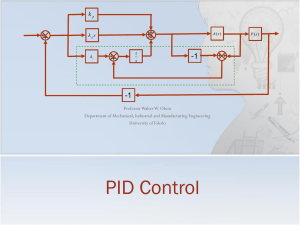

National Taiwan Ocean University Department of Communications, Navigation and Control Engineering A Two Degrees of Freedom PID Control System, its Features and Applications Masanori Yukitomo, Takashi Shigemasa , Yasushi Baba, Fumio Kojima Speaker:林湧傑 ID:19967042 Date:11/17/2010 Outline • Introduction • MD TDOF PID -Block diagram of a Model-Driven TDOF PID control system -A designing approach -Features -Practical industrial field experiments • Conclusions Introduction • PID為PD與PI結合而成的控制器,Gc(s)=Kp+KI/s+KDS。 優點:構造簡單,提供不錯的穩態誤差及相對穩定度 缺點:PID控制器的參數設計通常很困難, • MD PID:Model-Driven Control ,為了使參數調整簡單化而 設計,ex:IMC(Internal Model Control) and DMC(Dynamic Matrix Control)。 特色:構造簡單、增加穩定性及強健性、參數容易調整。 • MD TDOF PID :Model-Driven Two Degrees Of Freedom PID 目的 : 減少因為干擾造成的誤差,在不穩定的狀態中依然 可以使用 Block diagram of a Model-Driven TDOF PID control system (a)Set-point filter (b)Main controller: Gain . Q filter(second order) . Delay model with dead time(first order) (c) PD feedback compensator Designing Approach • Step 1:PD feedback compensator 功能: (a) stabilize even unstable processes P(s) (b) compensate the transfer function from v to y 設計方法: 找出P(s)的轉移函數,接著調整F(s) 讓G(s)近似於 Designing Approach • Step 2: Main Controller (a)KC = K :Gain (b)TC = T :Time constant (c)LC = L :Dead time • Step 3: Set-point filter 6 Features • Widely applicable process controller 透過PD feedback內各種參數的調整,可以將各種不同的程序 轉變成一階的延遲系統,因此這種PID對於各類系統的泛用性很 高。 • Two degrees of freedom characteristics 調整F 達到good tracking property without overshooting 調整Q 達到quick disturbance regulating property Practical industrial field experiments • Boiler test plant (a) 傳統PID(IMC) MD TDOF PID 以IAE(絕對誤差積分準則)及settling time(安定時間)來比較,MD TDOF PID 皆優於傳 統的PID Practical industrial field experiments • Boiler test plant (b) 傳統PID(IMC) MD TDOF PID 很明顯的,MD TDOF PID對於干擾的靈敏度以及矯正的能力皆優於傳統的PID 控制器 Practical industrial field experiments • Paper manufacturing plant Conclusions • The MD TDOF PID control system has strong capability to stabilize by using the PD feedback. • Various types of PID control systems can be realized from the MD TDOF PID control system smoothly by setting control parameters. • Through practical industrial field experiments, practical effectiveness for the MD TDOF PID Control system such as the quick responses for both set-point tracking and disturbance regulating response are shown. References • • • • • • • • [1] Araki Mitsuhiko, 2-degrees of freedom controller part I,Trans. Japan Associ. of Control Engineers,29, 649, 1985. [2] Astrom K.J. and T. Hagglund, PID Control Theory, Design and tuning, ISA, 1995. [3] Astrom K.J.,T.Hagglund, Benchmark systems for PID Control, Priprint of IFAC PID2000 Workshop, Terrassa, Spain, 2000. [4] Brosilow C., B. Joseph, Techniques of Model-Based Control, Prentice Hall publishes, 2002. [5] Control Technology Survey Report in Japan, Society of Instrument Control Engineers Japan,1996. (In Japanese) [6] Desborough L.,Randy Miller, Increasing Customer Value of Industrial Control Performance Monitoring , Preprints of Chemical Process control-6,153/186,Tucson, 2001. [7] Hiroi K. and Y. Terauchi, Two Degrees of Freedom Algorithm, Proceedings of the ISA , Houston, 1986. [8] Iino Y, T. Shigemasa, Practical Modeling and Control System Design Methods for CAE system,TP10-5:15,pp.1748-1753,The proceedings of the American Control Conference, Pittsburgh, 1989. References • • • • • • • [9] Kimura H, Is the Model a Good Controller? – Perspectives on Brain Motor Control,39 the IEEE Conference on Decision and Control, , Sydney, 2000. [10] Kitamori Toshiyuki, A design method for control systems based upon partial knowledge about controlled processes, Trans. of Society of Instrument and Control Engineers,15-4,549555, 1979. (In Japanese) [11] Kitamori Toshiyuki, Partial Model Matching Method conformable to Physical and Engineering Actualities,Preprints of 1st IFAC Symposium on System Structure and Control, 2001. [12] Morari M. and E. Zafiriou, Robust Process Control.,Prentice-Hall, Inc.Englewood Cliffs, N.J., 1989. [13] Rivera,D.E.,M.Morari,and S.Skogestad, “Internal Model Control 4.PID Controller Design, ”Ind.Eng. Chem. Process Des. Dev.25 ,252, 1986 [14] Shigemasa T., Y. Iino and M. Kanda, Two Degrees of Freedom PID Auto-tuning Controller, 87-1191, Proceedings of the ISA, Anaheim, 1987. [15] Shigemasa T., M. Yukitomo, R. Kuwata, T. Hattori and Y.Baba, A Model-Driven PID Controller, Proceedings of INTERMAC 2001, Tokyo, 2001. References • • • • • • [16] Shigemasa T., M. Yukitomo, R. Kuwata, A Model-Driven PID Control System and its Case Studies, PP.571/576, Proceedings of the 2002 IEEE International Conference on Control Applications Glasgow, 2002. [17] Shinskey F.G, PID-DEADTIME CONTROL OF DISTRIBUTED PROCESS, Preprint of the IFAC PID2000 Workshop, Terrassa, Spain, 2000. [18] Shinskey F.G, Feedback Controllers for the Process Industries, McGraw-Hill, 1994. [19] Starr J., Realization of truncated impulse responses with prescribed uncertainty, IFAC’81 world Congress, Kyoto, Japan, 1981. [20] Suda N., PID Control, Asakura Publishing Company, 1992.(In Japanese) [21] Takatsu H., T. Itou, Future Needs for Control Theory in Industry-- Report of the Control Technology Survey in Japanese Industry, IEEE Trans. on Control Systems Technology, 07-03, pp.298-305, 1999