20140225163517001

advertisement

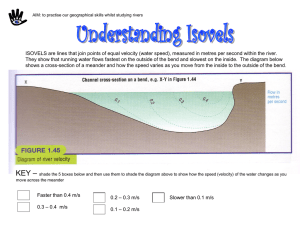

Surface viscous effect on surfactant transport onto a foam lamella Denny Vitasari, Paul Grassia, Peter Martin Foam and Minimal Surface, 24 – 28 February 2014 1 Background – Foam fractionation • Foam fractionation: Separation of surface active material using rising column of foam. Transport of surfactant onto the film interface determines the efficiency of a foam fractionation column. • Foam fractionation column with reflux: Some of the top product is returned to the column 2 Foam structure – Dry foam Lamella: thin film separating the air bubbles within foam. Plateau border: three lamellae meet at 120 to form an edge 3 2D illustration of a foam lamella • Due to reflux, the surface tension at the Plateau border is lower than that at the lamella transport of surfactant from the surface of Plateau border to the surface of film Marangoni effect. • Pressure in the Plateau border is lower due to curvature (Young-Laplace law) suction of liquid to the Plateau border film drainage. • Surface viscous effect takes place and opposes surface motion. 4 Aim Modelling the surface velocity profile and the surfactant transport onto a foam lamella in the presence of surface viscous stress. 5 Surface velocity profile Surface velocity film drainage Marangoni effect surface viscous effect Case without film drainage Simplification as benchmark for the real system Dimensionless surface velocity: Marangoni effect surface viscous effect 7 Illustration of a lamella and Plateau border 𝐿′ + 𝐿′ 𝑃𝑏 = 1 + 𝑎′ 𝜋 6 Boundary condition: 8 Parameters for simulation Foam film made from solution of Bovine serum albumin (BSA) with cosurfactant propylene glycol alginate (PGA) (Durand and Stone, 2006) Parameter Symbol Value Unit Characteristic `Marangoni’ time scale L2/(G0) 3.12510-2 s Initial half lamella thickness 0 2010-6 m Half lamella length L 510-3 m Liquid viscosity 710-3 Pa s Surface viscosity (31±12)10-3 Pa m s Curvature radius of the Plateau border s a 510-4 m Surfactant surface concentration at PB Pb 210-6 mol m-2 Initial surface concentration at film F0 110-6 mol m-2 9 Key parameters • 𝛿0′ 𝜇𝑠 (dimensionless surface viscosity parameter) is a • key parameter to determine the effect of surface viscosity upon the system. 𝑎′ (dimensionless radius of curvature of Plateau border relative to film length) determines magnitude of surface velocity near the Plateau border, hence the rate of surfactant transport onto the film. Parameter Range of values 𝛿0′ 𝜇𝑠 𝑎′ 2.7 × 10−4 − 5.4 × 10−2 0.1 − 0.3 10 Surface velocity: very small ′ δ0 𝜇 s Effect of surface viscosity only at the boundary layer near Plateau border Special case where 𝜕lnΓ′ 𝜕𝑥 ′ = 𝛽𝑥′ δ0𝜇s Surface movement slows down due to surface viscosity. 11 Surface velocity: very small δ′0 𝜇s Jump of Γ ′ = Γ0′ at 𝑥 ′ ≤ 𝑥0′ to Γ ′ = 1 at 𝑥 ′ ≥ 𝑥0′ With very small δ0𝜇s the surface velocity profile represents a Dirac delta function at 𝑥 ′ = 𝑥0′ Solution using Green’s function: 𝑥0′ = 0.5 • Largest magnitude of surface velocity at the jump point. • Surface viscous effect reduces peak surface velocity. • Flux near Plateau border in the absence of local Marangoni force there. 12 Surface velocity: ′ very small δ0 𝜇s Jump of Γ ′ = Γ0′ at 𝑥 ′ ≤ 𝑥0′ to Γ ′ = 1 at 𝑥 ′ ≥ 𝑥0′ Value of 𝑎′ relative to 𝑎′𝑐𝑟𝑖𝑡 determines the perturbation of surface velocity near Plateau border: • 𝑎′ < 𝑎′𝑐𝑟𝑖𝑡 upward perturbation from 𝑎′ = 𝑎′𝑐𝑟𝑖𝑡 • 𝑎′ > 𝑎′𝑐𝑟𝑖𝑡 downward perturbation from 𝑎′ = 𝑎′𝑐𝑟𝑖𝑡 13 Surface velocity: very small δ′0 𝜇s Jump of Γ ′ = Γ0′ at 𝑥 ′ ≤ 𝑥0′ to Γ ′ = 1 at 𝑥 ′ ≥ 𝑥0′ 𝑥0′ is shifted along the lamella length. The location of the largest magnitude of surface velocity shifts as the jump point shifts. 14 Surface velocity: ′ very small δ0 𝜇s Jump of Γ ′ = Γ0′ at 𝑥 ′ ≤ 1 to Γ ′ = 1 at 𝑥 ′ ≥ 1 Value of 𝑎′ relative to 𝑎′𝑐𝑟𝑖𝑡 determines the perturbation of surface velocity near Plateau border: • 𝑎′ < 𝑎′𝑐𝑟𝑖𝑡 upward perturbation from 𝑎′ = 𝑎′𝑐𝑟𝑖𝑡 • 𝑎′ > 𝑎′𝑐𝑟𝑖𝑡 downward perturbation from 𝑎′ = 𝑎′𝑐𝑟𝑖𝑡 15 General solution for arbitrary 𝜕lnΓ′ 𝜕𝑥′ Differential equation Integration of the Green’s function The Green’s function is easier to obtain when δ′0 𝜇𝑠 is small but more complicated to obtain when δ′0 𝜇𝑠 is larger. Finite difference approximation Applicable for arbitrary δ′0 𝜇s 16 Surface velocity profile • The turn around of surface velocity is less sharp at a later time due to surfactant surface concentration gradients being spread over larger distances, implying also a weaker Marangoni effect. • Weaker Marangoni effect results in lower surface velocity. 17 Surfactant transport via material point method • Surface velocity (𝑢𝑠 ) applies on every material point. • Surface excess () averaged between two material points. • Plot vs position 𝑥 • Surfactant is conserved between material points rectangle area preserved. 18 Evolution of surfactant surface concentration With surface viscosity δ′0 𝜇𝑠 = 0.0266 Without surface viscosity 19 Conclusions In the absence of film drainage, surface viscous effect balances the Marangoni force and slows down the surface movement. Jump of surfactant surface concentration: • Largest magnitude of surface velocity at the jump point. • Surface movement delocalized away from Marangoni surface tension gradients due to surface viscous effect (delocalisation distance ~ δ′0 𝜇𝑠 ) Critical radius of curvature of Plateau border: • 𝑎′ ≪ 𝑎′𝑐𝑟𝑖𝑡 ~ δ′0 𝜇𝑠 : magnitude of surface velocity greatly reduced by requirement to satisfy symmetry condition on midpoint of Plateau border face. In the presence of surface viscosity, the surface concentration of surfactant at a given time is lower than that without surface viscosity. 20 21