strains and stresses

advertisement

Element Loads

Strain and Stress

2D Analyses

Structural Mechanics

Displacement-based Formulations

Computational Procedure

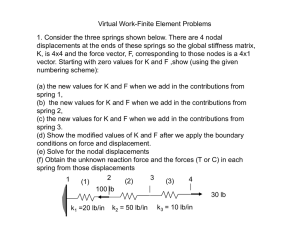

• Element Matrices:

– Generate characteristic matrices that describe element behavior

• Assembly:

– Generate the structure matrix by connecting elements together

• Boundary Conditions:

– Impose support conditions, nodes with known displacements

– Impose loading conditions, nodes with known forces

• Solution:

– Solve system of equations to determine unknown nodal displacements

• Gradients:

– Determine strains and stresses from the nodal displacements

Example B.C.’s

• Displacements are handled by moving the reaction influences to the right

hand side and creation of equations that directly reflect the condition

• Forces are simply added into the right hand side

No b.c.’s

N3

32426694.11 -7680008.00 -26666666.67

0.00

-7680008.00 10239972.56

0.00

0.00

-26666666.67

0.00 26666666.67

0.00

0.00

0.00

0.00 20000000.00

-5760027.44

7680008.00

0.00

0.00

7680008.00 -10239972.56

0.00 -20000000.00

32426694.11

-7680008.00

-7680008.00 10239972.56

0.00

0.00

0.00

0.00

0.00

0.00

7680008.00 -10239972.56

E2

E1

0.00

0.00

1.00

0.00

0.00

0.00

-5760027.44

7680008.00

7680008.00 -10239972.56

0.00

0.00

0.00 -20000000.00

5760027.44 -7680008.00

-7680008.00 30239972.56

0.00

0.00

0.00

1.00

0.00

0.00

u1

v1

u2

v2

u3

v3

0.00

7680008.00

0.00 -10239972.56

0.00

0.00

0.00

0.00

1.00

0.00

0.00 30239972.56

u1

v1

u2

v2

u3

v3

=

=

- or -

N2

N1

E3

32426694.11

-7680008.00

7680008.00

-7680008.00

10239972.56

-10239972.56

7680008.00

-10239972.56

30239972.56

u1

v1

v3

=

0

-1000

0

1000

This is it! Solve for the nodal displacements …

F1x

F1y

F2x

F2y

F3x

F3y

0.00

-1000

0.00

0.00

0.00

0.00

Other Loading Conditions

• Consider the assembled equation system [K] {D} = {F}

• The only things we can manipulate are:

– Terms of the stiffness matrix (element stiffness, connectivity)

– The unknown or specified nodal displacement components

– The applied nodal force components

• How do we manage “element” loads?

– Self-weight, structural systems where gravity loads are significant

– Distributed applied loads, axial, torsional, bending, pressure, etc.

Conversion to Nodal Loads

• All loads must be converted to nodal loads

• This is more difficult than it appears

• It is a place where FEA can go wrong and give you

bad results

• It has consequences for strain and stress calculation

q (N/m)

L

F=?

F=?

• You might guess F = qL/2, but why?

ddist

L

0

dconc

P (x)dx

1 L

qL2

qxdx

EA

EA 0

2EA

PL FL

EA EA

• Setting dconc = ddist:

F

qL

2

Consistent Nodal Loads

• Consistent nodal loading:

– Utilizes the same shape (interpolation) functions (more

later) as displacement shape functions for the element

– The bar (truss) shape functions specify linear displacement

variation between the nodes

– We choose a concentrated nodal force that results in an

equivalent nodal displacement to the distributed force

• Question: Are element strain and stress equivalent?

No

sx

x

sx

x

Strain and Stress Calculation

• For bar/truss elements with just nodal boundary conditions:

– Find axial elongation DL from differences in node displacements

– Find axial strain e from the normal strain definition

– Find axial stress sfrom the stress-strain relationship

• Even when models become more complicated (higher order

displacement/strain relationship, complex constitutive model)

this is the general approach

DL from nodal displacements

DL

e

L

s Ee

Adjusting Strain and Stress

• Add analytically-derived fixed-displacement strain and stress

• This must be done for thermally-induced distributed loading

sx

x

sx

+

Note the added

constraint …

x

Mesh Refinement

• What if we model a bar (truss) or beam element not

as a single element, but as many elements?

• No gain is made in displacement prediction

– Holds true for node and element loading

• Strain and stress prediction improve

– Results converge toward the analytical solution even

without inclusion of “fixed-displacement analytical stress”

Piece-wise Interpolation

• If you remember nothing else about FEA, remember this …

sx

x

sx

These are not always flat …

2D/3D elements extend this

behavior dimensionally …

x

To Refine, or Not To Refine …

• It depends on the purpose of the analysis, the types

of elements involved, and what your FEA code does

• For bar (truss) and beam elements:

–

–

–

–

Am I after displacements, or strain/stress?

Does my FEA code include analytical strain/stress?

What results does my FEA code produce?

Can I just do my own post-processing?

• Always refine other element types