Stratégies de régularisation et enjeux d`identification

advertisement

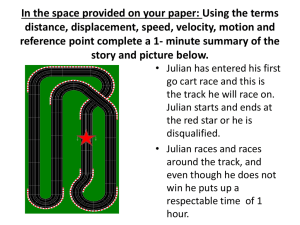

Corrélation d'images numériques: Stratégies de régularisation et enjeux d'identification Stéphane Roux, François Hild LMT, ENS-Cachan Atelier « Problèmes Inverses », Nancy, 7 Juin 2011 • Image 2 Image 1 Relative displacement field ? • Image 1 Image 2 Image # 11 Image # 1 100 100 200 200 300 300 400 400 500 • 500 600 600 700 700 800 800 900 900 1000 1000 200 400 600 800 1000 200 400 600 800 Deformed image Reference image Relative displacement field ? 1000 Image # 11 Image # 1 100 100 200 200 300 300 400 400 500 • 500 600 600 700 700 800 800 Displacement field Uy 900 1000 200 400 600 Reference image 800 900 1000 1000 200 400 600 800 Deformed image 100 200 300 400 500 600 700 800 900 200 400 600 800 1000 Displacement fields are nice, but … Can we get more ? Stress intensity Factor, Crack geometry Uy Image 1 0.25 450 500 0.2 550 0.15 600 0.1 650 700 0.05 750 0 800 -0.05 850 200 300 400 500 600 700 Image 2 Image # 11 Image # 1 100 100 200 200 300 300 400 400 500 500 600 600 700 700 800 900 1000 200 400 600 800 800 Damage field 1000 900 1000 200 400 600 800 Deformed image Reference image 200 -0.5 400 -1 600 -1.5 800 log -2 200 400 600 800 1000 10 (1 D ) 1000 Image # 11 Image # 1 100 100 200 200 300 300 400 400 500 500 600 600 700 700 800 800 Constitutive law 900 1000 200 400 600 800 Reference image 1000 900 1000 200 1 0.8 0.6 0.4 0.2 0 0 600 800 Deformed image 1.2 D 400 1 2 3 4 5 x 10 -3 2 eq 1000 Outline • A brief introduction to “global DIC” • Mechanical identification • Regularization From texture to displacements DIC IN A NUTSHELL Digital Image Correlation • Images (gray levels) indexed by time t f ( x, t) • Texture conservation (passive tracers) f ( x , t 0 ) f ( x u ( x , t1 ) , t1 ) (hypothesis that can be relaxed if needed) Problem to solve • Weak formulation: Minimize wrt u ( x , t ; t0 ) d x d t 2 2 where the residual is ( x , t1 ; t 0 ) f ( x , t 0 ) f ( x u ( x , t1 ) , t1 ) Provides a spatially resolved quality field of the proposed solution Solution • The problem is intrinsically ill-posed and highly non-linear ! • A specific strategy has to be designed for accurate and robust convergence • It impacts on the choice of the kinematic basis Global DIC • Decompose the sought displacement field on a suited basis providing a natural regularization u( x, t) u n Yn ( x , t ) n • Yn: – FEM shape function, X-FEM, … – Elastic solutions, Numerically computed fields, Beam kinematics… The benefit of C0 regularization ZOI size / Element size (pixels) Key parameter = (# pixels)/(# dof) Example: T3-DIC* Pixel size = 67 mm *[Leclerc et al., 2009, LNCS 5496 pp. 161-171] Example: T3-DIC Example: T3-DIC Ux (pixel) 0.46 0.28 0.11 -0.06 -0.23 [H. Leclerc] Example: T3-DIC Uy (pixel) 0.54 0.35 0.15 -0.04 -0.24 Example: T3-DIC Example: T3-DIC Residual 28 21 14 7 0 Mean residual = 3 % dynamic range IDENTIFICATION The real challenge • For solid mechanics application, the actual challenge is – not to get the displacement fields, but rather – to identify the constitutive law (stress/strain relation) • The simplest case is linear elasticity Plane elasticity • A potential formulation can be adopted showing that the displacement field can be written generically in the complex plane as 2 mU k ( z ) z ' ( z ) Y ( z ) where and Y are arbitrary holomorphic functions • m is the shear modulus, • k is a dimensionless elastic constant (related to Poisson’s ratio) Plane elasticity • It suffices to introduce a basis of test functions for (z) and Y(z) and consider that ( z ) and z ' ( z ) Y ( z ) are independent • Direct evaluation of 1/m and k/m Validated examples • Brazilian compression test • Cracks Example 1: Brazilian compression test • Integrated approach: decomposition of the displacement field over 4 fields (rigid body motion + analytical solution) Integrated approach Integrated approach Identified properties for the polycarbonate m 880 MPa n 0.45 In good agreement with literature data Need for coupling to modelling • Elasticity (or incremental non-linear behavior) (1 / 2 )( U U t ) C .. f 0 • FEM KU F div ( C .. U ) f 0 Dialog DIC/FEA modeling • Local elastic identification R. Gras, Comptest 2011 T4-DVC 33 More general framework • Inhomogeneous elastic solid • Non-linear constitutive law – Plasticity – Damage – Non-linear elasticity Image # 11 Image # 12 100 100 200 200 300 300 400 400 500 500 600 600 700 700 800 800 900 900 1000 1000 200 400 600 800 1000 200 400 600 800 1000 REGULARIZATION Mechanical regularization • The displacement field should be such that div( C : U ) 0 or in FEM language K .U 0 for interior nodes. This can be used to help DIC Integrated DIC • Reach smaller scale H. Leclerc et al., Lect. Notes Comp. Sci. 5496, 161-171, (2009) Tikhonov type regularization • Minimization of f ( x U , t1 ) f ( x , t 0 ) 2 A KU 2 • Regularization is neutral with respect to rigid body motion • How should one choose A ? Spectral analysis • For a test displacement field f ( x U , t1 ) f ( x , t 0 ) KU log(||.||2) 2 k V 4 2 U V exp( ik . x ) V 2 A 2 Regularization DIC Cross-over scale log(k) 4 Boundaries • The equilibrium gap functional is operative only for interior nodes or free boundaries • At boundaries, information may be lacking – Introduce an additional regularization term 2 2 (e.g. U ) – Extend elastic behavior outside the DIC analyzed region Regularization at voxel scale • An example in 3D for a modest size 243 voxels Voxel scale DVC 1 voxel 5.1 µm Displacement norm (voxels) Vertical displacement (voxels) H. Leclerc et al., Exp. Mech. (2011) NON-LINEAR IDENTIFICATION Identification • As a post-processing step, a damage law can be identified from the minimization of 2 (1 D )K i i kl Ul elements i where U has been measured and K is known • Many unknowns ! Validation < 5.3 % Constitutive law State potential (isotropic damage) Y (1 / 2 ) ε : E 0 (1 D ) ε σ Y ε State laws Y E 0 (1 D ) ε Y D 1 2 ε : E 0ε Dissipated power Thermodynamic consistency d Y D 0 D 0 and Y 0 Growth law (1 D ) function of ( 2 / E 0 )Y ~ equivalent scalar strain Use of a homogeneous constitutive law • Postulating a homogeneous law, damage is no longer a two dimensional field of unknowns, but a (non-linear) function of the maximum strain experienced by an element of volume. Damage growth law • Identified form D 1 n 0.8 truncation D n 1 Y an E 1.2 or D 0.6 0.4 n 1 a n (1 exp( Y / y n ) ) 0.2 0 0 1 2 Y 3 5 4 x 10 -3 Identified damage image 10 Identified log10(1-D) image 10 -0.5 200 400 -1 600 -1.5 800 -2 200 400 600 800 1000 Identified damage image 11 Identified log10(1-D) image 11 log10(1-D) 200 -0.5 400 -1 600 -1.5 800 -2 200 400 600 800 1000 Identified damage image 11 Identified log10(1-D) image 11 Image # 11 Image # 12 100 100 200 200 -0.5 300 300 400 400 -1 500 600 -1.5 800 -2 200 400 600 800 1000 500 700 800 800 900 400 600 600 700 1000 200 200 400 600 800 1000 900 1000 200 400 600 800 1000 Validation image 10 Identified Ux Measured Ux 4 200 400 600 800 2 0 -2 500 1000 200 400 600 800 -4 0 -2 1000 0 -2 1000 -4 Identified Uy 2 500 2 500 Measured Uy 200 400 600 800 4 -4 2 200 400 600 800 0 -2 -4 500 1000 Validation image 11 Identified Ux Measured Ux 5 200 400 600 800 0 500 1000 -5 200 400 600 800 0 -2 -4 1000 -5 1000 Identified Uy 2 500 0 500 Measured Uy 200 400 600 800 5 2 200 400 600 800 0 -2 -4 500 1000 CONCLUSIONS Conclusions • DIC and regularization can be coupled to make the best out of difficult measurements • A small scale regularization is too poorly sensitive to elastic phase constrast to allow for identification • Yet, post-treatment may provide the sought constitutive law description • Fusion of DIC and non-linear identification is the most promising route