bernoulli`s equation - EngineeringDuniya.com

advertisement

BERNOULLI’S EQUATION

• Bernoulli’s equation states that the sum of

all forms of energy in a fluid flowing along

an enclosed path is the same at any two

points in that path.

• Assumptions:

– Flow is steady

– Density is constant (incompressible)

– Friction losses are negligible

BERNOULLI’S EQUATION

• By conservation of energy,

(Energy)1 = (Energy)2

Σ(Energy) = 0

{D (Press. forces) + D (Kinetic Energy) +

D (Potential Energy)} = 0

•

•

•

•

Pressure forces = F S

Kinetic Energy = ½ m v2

Potential energy = m g h

Pressure forces @ 1 are given by,

F1 S1 p1 A1v1Dt

A1v1 p1 Dt

m

p1 Dt

m

p1 Dt

Dt

F1 S1

m p1

• Sub. all the values in the energy balance

equation:

1

1

2

2

F1 S1 mv1 mgh1 F2 S 2 mv 2 mgh 2

2

2

p1

p2 1 2

1 2

m m v1 m gh1 m

m v2 m gh2

2

2

p1

p2 1 2

1 2

v1 gh1

v2 gh2

2

2

p

2

v

OR

gh constant

2

Applications of B.Eqn:

• B.E often combined with continuity

equation to find velocities & pressures in

the flow connected by a streamline

• Orifice meter; venturi meter

• Flow in pumps etc.,

Fluid friction……

• Fluid friction is defined as any conversion of

mechanical energy into heat in a flowing stream

• Denoted by the letter hf (J/kg)

• hf represents all the friction generated per unit

mass of fluid bet (1) & (2)

• B.E becomes……..

p1

p2 1 2

1 2

v1 gh1

v2 gh2 h f

2

2

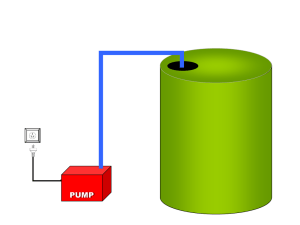

Pump work…….

• If a pump is used during flow, then the term “work

done by the pump” should be added to B.E

p1

p2 1 2

1 2

v1 gh1 W p

v2 gh2

2

2

Prob 1

• A fluid of density 960 kg/m3 is flowing

steadily thro a tube as shown in the fig:

The sections diameters are d1=100mm &

d2=80mm. The press p1 =200kN/m2;

u1=5m/s. The tube is horizontal. What is

the pressure at section(2)?

• By continuity equation:

m 1v1 A1 2 v 2 A2

• v2 = 7.8125 m/s

• From B.E….

p1

p2 1 2

1 2

v1 gh1

v2 gh2

2

2

• p2 = 182.703 x 103 N/m2

Prob 2

• Gasoline(680 kg/m3) flows from a 0.3m dia

pipe in which the pressure is 300kPa into

a 0.15m dia pipe in which the press is

120kPa. If the pipes are horizontal &

viscous effects are negligible, determine

the flow rate:

• By continuity equation:

m 1v1 A1 2 v 2 A2

• v2 = 4 v 1

• From B.E….

• v1= 5.94 m/s

• Flow rate, Q = A1v1 = 0.4199 m3/s

Prob 3

• Water flows steadily thro’ the pipe shown

in fig. such that the press @ sections 1 & 2

are 300kPa & 100kPa respectively.

Determine the dia of pipe @ section 2, if

the velocity at section 1 is 20m/s and

viscous effects are negligible:

• From B.E….

• v2= 42.2 m / s

• By continuity equation:

m 1v1 A1 2 v 2 A2

• D2 = 0.0688m

Prob 4

Water with a density of 998 kg/m3 is flowing at a steady

mass flow rate through a uniform-diameter pipe. The

entrance pressure of the fluid is 68.9 kN/m2 in the pipe,

which connects to a pump which actually supplies 155.4

J/kg of fluid flowing in the pipe. The exit pipe from the

pump is the same diameter as the inlet pipe. The exit

section of the pipe is 3.05 m higher than the entrance, and

the exit pressure is 137.8 kN/m2. The Reynolds number in

the pipe is above 4000 in the system. Calculate the

frictional loss hf in the pipe system.

• From B.Eqn:

p1

p2 1 2

1 2

v1 gh1 W p

v2 gh2 h f

2

2

• Since dia of pipe is same…….v1 = v2

• hf = 56.44 J/kg

Prob 5

• A pump draws 69.1 gal/mm of a liquid solution

having a density of 114.8 lbm/ft3 from an open

storage feed tank of large cross-sectional area

through a 3.068”ID suction line. The pump

discharges its flow through a 2.067”ID line to an

open overhead tank. The end of the discharge

line is 50 ft above the level of the liquid in the

feed tank. The friction losses in the piping

system are 10.0 ft-lbf /lbm. What is the

horsepower of the pump if its efficiency is 65%?

What pressure must the pump develop?

• = 114.8 lbm/ft3

• =114.8 (0.454) / (0.3048)3

• Therefore, = 1840.6 kg/m3

• hf = 10 ft-lbf / lbm

• =10(0.3048m)(4.4482N) / (0.454)

• Therefore, hf = 29.864 J/kg

• Apply B.Eqn bet (1) & (2)

p1

p2 1 2

1 2

v1 gh1 W p

v2 gh2 h f

2

2

•

•

•

•

Since p1 = p2 (open to atmosphere)

h1 – h2 = 50’ = 15.24m

v2 = 2.0315 m/s (for 2.067”)

Since tank dia is very high…..v1<<v2 { v1/v2 =

A1/A2}

• v1 = 0

• Sub all values in B.Eqn….Wp = 2239.057 J/s

• Or Wp = 3.005 HP {1HP = 745 W}

• The press. developed in the pump (ie bet 3 & 4)

p3

p4 1 2

1 2

v3 gh3 W p

v4 gh4 h f

2

2

• Since hf is only for piping system…..here for

pump…..hf = 0

• h3 = h4 and v4 = v2 = 2.035 m/s

• v3 = 0.91395 m/s (for 3.068”)

• Sub all the values in the B.Eqn….

• (p3 – p4) = 330.833 kPa…..pressure developed

by the pump

Time for emptying a tank

• Consider a steady flow of water from a

tank of height H

• Hi and Hf are initial & final height of water

in the tank

• Applying B.Eqn….

p1

p2 1 2

1 2

v1 gh1

v2 gh2

2

2

v2 2gH

• We know, Q1 = Q2

dH

At

A2 v2

dt

Hf

At

Hi

At

tf

A2

dH

2 gH

1

2g

A2 t f

2 Hi H f

Prob 6

• Draining Cotton Seed Oil from a Tank

A cylindrical tank 1.52 m in dia and 7.62 m high

contains cotton seed oil having a density of 917

kg/m3. The tank is open to the atmosphere. A

discharge nozzle of inside diameter 15.8mm and

cross-sectional area A2 is located near the bottom of

the tank. The surface of the liquid is located at

H = 6.1 m above the center line of the nozzle. The

discharge nozzle is opened, draining the liquid level

from H=6.1 m to H=4.57 m. Calculate the time in

seconds to do this.

• We know,

At

tf

A2

1

2g

• At = CSA of tank = (p/4)D2

• Therefore, t = 1387 sec

2 Hi H f