Q = U 0 A 0 Δt m

advertisement

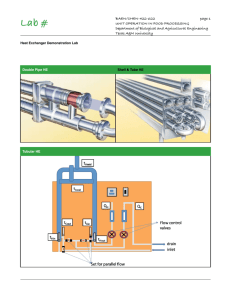

Objectives • Continue with heat exchangers (ch.11) Coil Extended Surfaces Compact Heat Exchangers • Fins added to refrigerant tubes • Important parameters for heat exchange? Overall Heat Transfer Q = U0A0Δtm Overall Heat Transfer Coefficient Mean temperature difference Heat Exchangers • Parallel flow • Counterflow • Crossflow Ref: Incropera & Dewitt (2002) Heat Exchanger Analysis - Δtm Heat Exchanger Analysis - Δtm Counterflow t m or t m t h ,o tc ,i t h ,i tc ,o t h ,o tc ,i ln t t h ,i c , o t B t A t B ln t A For parallel flow is the same t m t B t A t B ln t A Counterflow Heat Exchangers th,o tc,i th,i tc,o tc,o tc,i R 1 tm t ln th,o tc,i th,i tc,o m 1 P ln 1 RP Important parameters: t h , i t h, o R tc,o tc,i tc, o tc ,i P th,i tc,i Q = U0A0Δtm Heat exchanger effectiveness • Generally for all exchanger • Losses to surrounding 0 • Then: Q cold fluid = Q hot fluid • mccp_c(tc,o-tc,i)=mhcp_h(th,i-th,o) • Effectiveness = Q exchanged / Q maximum = Q cold or hot fluid / Q maximum Heat Exchanger Effectiveness (ε) (notation in the book) C=mcp Mass flow rate Specific capacity of fluid THin TCout THout TCin Location B Location A Heat exchangers Air-liquid Tube heat exchanger Air-air Plate heat exchanger Example Assume that the residential heat recovery system is counterflow heat exchanger with ε=0.5. Calculate Δtm for the residential heat recovery system if : mcp,hot= 0.8· mc p,cold Outdoor Air 32ºF mc p,cold 72ºF mcp,hot= 0.8· mc p,cold 72ºF Combustion products Exhaust Furnace Fresh Air th,i=72 ºF, tc,i=32 ºF For ε = 0.5 → th,o=52 ºF, tc,o=48 ºF Δtm,cf=(20-16)/ln(20/16)=17.9 ºF 0.2· mc p,cold What about crossflow heat exchangers? Δtm= F·Δtm,cf Correction factor Δt for counterflow Derivation of F is in the text book: ……… Overall Heat Transfer Q = U0A0Δtm Need to find this AF AP,o 1 1 U0 Ro RInternal Rcond Pipe RExternal Resistance model Q = U0A0Δtm From eq. 1, 2, and 3: U0 1 Ao AP ,i hi R Internal Ao x p AP ,m k p R cond-Pipe 1 AP ,o hc ,o A F hc1,o R External • We can often neglect conduction through pipe walls • Sometime more important to add fouling coefficients Example The air to air heat exchanger in the heat recovery system from previous example has flow rate of fresh air of 200 cfm. With given: h Internal 10 Btu/hsfF, R cond 0.002sfF/Btu/h , h External 10 Btu/hsfF Calculate the needed area of heat exchanger A0=? Solution: Q = mcp,cold Δtcold = mcp,hot Δthot = U0A0Δtm From heat exchanger side: Q = U0A0Δtm → A0 = Q/ U0Δtm U0 = 1/(RInternal+RCond+RFin+RExternal) = (1/10+0.002+0+1/10) = 4.95 Btu/hsfF Δtm = 16.5 F From air side: Q = mcp,cold Δtcold = = 200cfm·60min/h·0.075lb/cf·0.24Btu/lbF·16 = 3456 Btu/h Then: A0 = 3456 / (4.95·16.5) = 42 sf For Air-Liquid Heat Exchanger we need Fin Efficiency • Assume entire fin is at fin base temperature • Maximum possible heat transfer • Perfect fin • Efficiency is ratio of actual heat transfer to perfect case (tF , m t ) /(tF , B t ) • Non-dimensional parameter tF,m Fin Theory k – conductivity of material hc,o – convection coefficient pL=L(hc,o /ky)0.5 Fin Efficiency • Assume entire fin is at fin base temperature • Maximum possible heat transfer • Perfect fin • Efficiency is ratio of actual heat transfer to perfect case • Non-dimensional parameter