File

advertisement

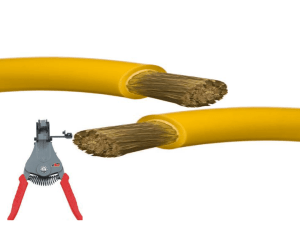

E4 Electrical Installation #2 Wire Sizing and Materials AMP AMPACITY ACITY • Ampacity is: The AMPerage handling capACITY of wire, fuse, or CB • It is the amperage draw PLUS a 25% safety factor Or, the amperage load x 1.25 = Ampacity • Example: Name plate amperage is 12 amps 12 amps load x 1.25 = 15 amps ampacity • Ampacity is the value used to determine the correct size of wires, fuses, and circuit breakers for inductive (motor) loads © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 2 Wire Insulation • The insulation on a wire is a factor in its rated ampacity • Examples of wire insulation descriptions: • TW – Thermoplastic, Wet (and dry) locations • THHN – Thermoplastic, High-Heat resistant, Nylon © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 3 Wire sizing • Wire is rated in AWG (American Wire Gauge) • The lower the number, the thicker the wire • The lower the number, the higher the amperage capacity © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 4 Ampacity and Wire Insulation Wire size AWG Ampacity for Ampacity for Type TW & UF Type THHN Maximum Amp Ratings* # 14 20 25 15* # 12 25 30 20* # 10 30 40 30* *According to the electrical code, the overcurrent protection shall not exceed 15A for #14, 20A for #12, or 30A for #10 (However, insulation is a factor in locations above 86 F) © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 5 Wire Marking • Marking on the cable usually indicates wire type, insulation, conductor size, and application. Following are some examples: – NM: Non Metallic casing enclosing the wire – MC: Metal Clad casing enclosing the wire – UF: Underground Feeder – SEC: Service Entrance Cable – #12 AWG: Size 12 American Wire Gauge © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 6 Some Examples of Common Indoor Wiring Materials • Non Metallic cable (NM, Romex®) • Armored cable (AC, MC, BX) • Rigid Metallic Conduit (EMT, “Thinwall”) © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 7 “Romex” Type TW insulation Two #12 wires with a bare ground wire Non-metallic cable © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 8 MC (Metal Clad) or Armored Cable (AC) Insulating Bushing © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 9 Electric Metallic Tubing (EMT) Coupling © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 Connector 10 Outdoor Wiring • For outdoor condensing units, the wiring materials must be flexible, liquid tight, and damage resistant • Following is one example of the wiring used © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 11 Flexible Liquid Tight Conduit Coiled metal for flexible strength 90 ° Connector Plastic sheathing to make it “liquid tight” © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 12 Unit Ratings • The unit data plate contains important electrical information • Based on the information on the following slide, wire and circuit breaker sizes can be determined © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 13 Sample A/C Electrical Data Unit Rating 7 ½ Tons Compressor Compressor RLA LRA 208/230-3-60 19.0 142 Voltage OFM FLA 1.9 MCA MOCP 25.6 35 What is the wire size and circuit size for the above unit? A unit with 25.6 ampacity (MCA) requires: a minimum 30 amp circuit # 10 wire The circuit may be fused at a maximum of 35 amps (MOCP) Note: For ampacity calculations of a multi-motor assembly, 25% is added only to the largest motor. Example: 19.0 x 1.25 = 23.75 + 1.9 for OFM = 25.6 MCA RLA – Rated Load Amps LRA – Lock Rotor Amps OFM – Outside Fan Motor LEGEND FLA – Full Load Amps MCA – Minimum Circuit Amps MOCP – Max.*Overcurrent Protection *Note: The overcurrent protection device must be a fuse or HACR breaker. © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 14 Common HVACR Ratings • The following table is a useful guideline for determining the wire and circuit breaker sizes for the most common motor amperages © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 15 Wire and Circuit Breaker Sizing for Motor Loads Total Unit Amps Circuit Breaker Amps Wire Size 0 – 12 15 # 14 13 – 16 20 # 12 17 – 24 30 # 10 25 - 32 40 #8 33 - 48 60 #6 © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 16 © 2005 Refrigeration Training Services - E4#2 Wire Sizing and Materials v1.2 17