Lecture 10

advertisement

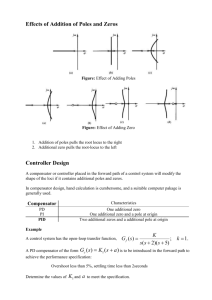

INC341 Design Using Graphical Tool (continue) Lecture 10 INC 341 PT & BP Improving Both Steady-State Error and Transient Response • PI, Lag improve steady-state error • PD, Lead improve transient response • PID, Lead-lag improve both (PID = Proportional plus Intergal plus Derivative controller) INC 341 PT & BP PID Controller K1s K 2 K 3 s 2 K2 Gc ( s) K1 K3s s s INC 341 K 3 (s 2 K1 K s 2) K3 K3 s PT & BP PID controller design 1. Evaluate the performance of the uncompensated system 2. Design PD controller to meet transient response specifications 3. Simulate and Test, redesign if necessary 4. Design PI controller to get required steadystate error 5. Find K constant of PID 6. Simulate and Test, redesign if necessary INC 341 PT & BP Example Design PID controller so that the system can operate with a peak time that is 2/3 of uncompensated system, at 20% OS, and steady-state error of 0 for a step input INC 341 PT & BP Step 1 • %OS = 20% damping ratio = 0.456 Ѳ = 62.87 • Search along ther line to find a point of 180 degree (-5.415±j10.57) • Find a correspoding K=121.51 • Then find the peak time Tp INC 341 0.297sec d 10.57 PT & BP INC 341 PT & BP Step 2 • Decrease peak time by a factor of 2/3 get imaginary point of a compensator pole: d Tp (2 / 3)(0.297) 15.867 • To keep a damping ratio constant, real part of the pole will be at d tan(62.87 ) 8.13 • The compensator poles will be at -8.13±j15.867 INC 341 PT & BP • Sum of the angles from uncompensated poles and zeros to the test point (-8.13±j15.867) is -198.37 • The contribution angle for the compensator zero is then 180-198.371 = 18.37 15.87 tan(18.37 ) zc 8.13 zc 55.92 ดPD controller is (s+55.92) INC 341 PT & BP INC 341 PT & BP Step 3 • Simulate the PD compensated system to see if it reduces peak time and improves ss error INC 341 PT & BP Step 4 • design PI compensator (one pole at origin and a zero near origin; at -0.5 in this example) s 0 .5 GPI ( s ) s • Find a new point along the 0.456 damping ratio line (-7.516±j14.67), with an associate gain of 4.6 INC 341 PT & BP INC 341 PT & BP Step 5 • Evaluate K1, K2, K3 of PID controller K ( s 55.92)( s 0.5) s 4.6( s 55.92)( s 0.5) s G PID ( s ) 4.6( s 2 56.42s 27.96) s • Compare to K1 s K 2 K 3 s 2 Gc ( s ) s K1 = 259.5, K2 = 128.6, K3 = 4.6 INC 341 PT & BP Step 6 INC 341 PT & BP Lead-Lag Compensator Design Same procedures as in designing PID: – Begin with designing lead compensator to get the desired transient response – design lag compensator to improve steadystate error INC 341 PT & BP Example Design lead-lag compensator so that the system can operate with 20% OS, twofold reduction in settling time, and tenfold improvement in steady-state error for a ramp input INC 341 PT & BP Step 1 • %OS = 20% damping ratio = 0.456 Ѳ = 62.87 • Search along ther line to find a point of 180 degree (-1.794±j3.501) • Find a correspoding K=192.1 • Then find the settling time Ts INC 341 4 4 2.230sec 1.794 PT & BP INC 341 PT & BP Step 2 • Decrease settling time by a factor of 2 get a real part of a compensator pole: 4 4 3.588 Ts (1 / 2)(2.230) • To keep a damping ratio constant, imaginary part of the pole will be at d 3.588tan(62.87 ) 7.003 • The compensator poles will be at -3.588±j7.003 INC 341 PT & BP • Select the compensator zero at -6 to coincide with the open-loop pole • Sum of the angles from uncompensated poles and zeros to the test point (-3.588±j7.003) is -164.65 • The contribution angle for the compensator zero is then 180-164.65 = 15.35 7.003 pc 3.588 tan(15.35 ) pc 29.1 Lead compensator is ( s 6) ( s 29.1) INC 341 PT & BP Then find a new K at the design point (K=1977) INC 341 PT & BP Step 3 Simulate the lead compensated system INC 341 PT & BP Step 4 • Originally the uncompensated system has the transfer function: K G (s) , K 192.1 s ( s 6)( s 10) INC 341 192.1 Kv 3.201 6 10 PT & BP • After adding the lead compensator, the system has changed to G LC ( s ) 1977 s ( s 10)( s 29.1) • Static error constant, Kv, is then 6.794 (lead compensator has improved ss error by a factor of 6.794/3.201=2.122) • So the lag compensator must be designed to improve ss error by a factor of 10/2.122=4.713 Glag ( s ) INC 341 (s zc ) zc , 4.713 ( s pc ) pc PT & BP Step 5 • Pick a pole at 0.01, then the associated zero will be at 0.04713 Glag ( s ) ( s 0.04713) ( s 0.01) • Lag-lead compensator Glead lag ( s ) ( s 6)( s 0.04713) ( s 29.101)( s 0.01) • Lag-lead compensatated open loop system G LLC ( s ) INC 341 K ( s 0.04713) s ( s 10)(s 29.101)( s 0.01) PT & BP INC 341 PT & BP INC 341 PT & BP Step 6 INC 341 PT & BP Conclusions INC 341 PT & BP INC 341 PT & BP Feedback Compensation Put a compensator in the feedback path INC 341 PT & BP Tachometer Popular feedback compensator, rate sensor Tachometer generates a voltage output proportional to input rational speed INC 341 PT & BP rate feedback INC 341 PT & BP Example Design a feedback compensator to decrease settling time by a factor of 4 and keep a constant %OS of 20 INC 341 PT & BP Step 1 %OS = 20% damping ratio = 0.456 Ѳ = 62.87 Search along the daping ratio line to get a summation of angle of 180 degrees at -1.809±j3.531 Find the corresponding K from the magnitude rule K 1.8092 3.5312 3.1912 3.5312 13.1912 3.5312 257.841 settling time INC 341 4 4 Ts 2.21 sec 1.809 PT & BP Step 2 Reduce the Settling time by a factor of 4 4 4 7.236 Ts (1 / 4)(2.21) d 7.236tan(62.87 ) 14.123 A new location of poles is at -7.236±j14.123 INC 341 PT & BP At dominant pole -7.236±j14.123, KG(s)H(s) has a net angle of = -277.33 needs an additional angle from zero of 277.33-180 = 97.33 14.123 tan(180 97.33 ) 7.236 zc zc 5.42 Find the corresponding K to the pole at -7.236+j14.123 using the magnitude rule: K ( s 5.42) s( s 5)(s 15) K = 256.819 INC 341 PT & BP K1 K f 256.819 1 5.42 Kf K f 0.185 K1 1388.211 Feedback block is 0.185(s+5.42) INC 341 PT & BP Physical System Realization PI Compensator R2 1 s R C R2 2 C ( s) R1 s C R1 Vi(s) INC 341 Vo(s) PT & BP Lag Compensator R1 Vi(s) Vo(s) R2 C INC 341 1 s R2 R2C Gc ( s ) 1 R1 R2 s ( R1 R2 )C PT & BP PD Compensator R2 C Vi(s) R1 INC 341 Vo(s) 1 Gc ( s) R2C s R C 1 PT & BP Lead Compensator R1 Vi(s) Vo(s) C R2 1 s R1C Gc ( s ) 1 1 s R1C R2C s zc , zc pc s pc INC 341 PT & BP PID Compensator R2 C2 R1 Vi(s) Vo(s) C1 1 R C R C Gc ( s) 2 1 R2C1s 1 2 s R1 C2 INC 341 PT & BP