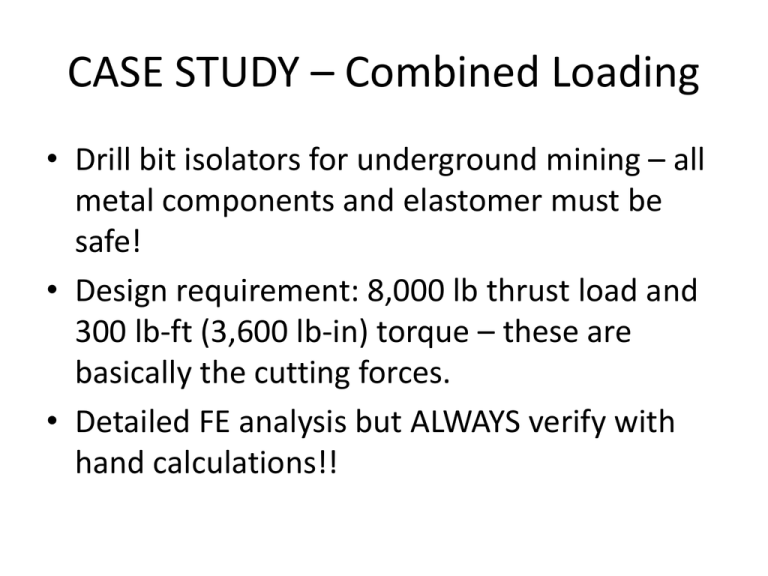

CASE STUDY – Combined Loading

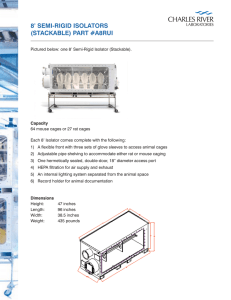

advertisement

CASE STUDY – Combined Loading • Drill bit isolators for underground mining – all metal components and elastomer must be safe! • Design requirement: 8,000 lb thrust load and 300 lb-ft (3,600 lb-in) torque – these are basically the cutting forces. • Detailed FE analysis but ALWAYS verify with hand calculations!! Bit Isolator Drill Depth up to 48” Chuck Isolator 2010 SME Annual Meeting & Exhibit Phoenix, Arizona 35 mm (1 3/8 in) Isolator Load Requirements: Drill Bit Drill Bit Isolator ( Thrust Load = 8,000 to 10,000 lb Bending Load= 125 lbs)= K*d Drill Rod Torsion Load= 300 lb-ft Chuck Isolator HOT SPOT! 2010 SME Annual Meeting & Exhibit Phoenix, Arizona Results showed that in combination, the bit isolator and the drill chuck isolator provided a 7 dB(A) reduction in sound pressure level at the operator position. 2010 SME Annual Meeting & Exhibit Phoenix, Arizona A-weighted Sound Level Spectrum 110 108.9 dB(A) Baseline: T2 - 45 NR BISO, 45 NR CISO: 104.4 dB(A) 105 A-weighted Sound Level (dB) T5 - 55 NR BISO, 55 NR CISO: 102.7 dB(A) 100 T7 - 70 NR BISO, 70 NR CISO: 104.4 dB(A) 95 90 85 80 75 70 65 Overall Phoenix, Arizona 10000 2010 SME Annual Meeting & Exhibit 8000 1/3-Octave-Band Center Frequency (Hz) 6300 5000 4000 3150 2500 2000 1600 1250 1000 800 630 500 400 315 250 60 1 3/8” Drill Bit Isolator – Design Review: Drill Bit isolator: Chuck isolator: 2010 SME Annual Meeting & Exhibit Phoenix, Arizona 1 3/8" DBI, R. Michael, PE 6 Critical Area!! Look at metal components: Where would you expect max stress to occur? 4/13/2015 1 3/8" DBI, R. Michael, PE 7 Critical component – inner member, thin wall, stress concentration! Results: FE Analysis 1 3/8” DBI All cases, thurst load = 8,000 lb, torque = 300 lb-ft (3,600 lb-in) HOT SPOT! 4/13/2015 1 3/8" DBI, R. Michael, PE 9 Max Principal, s1 Min Principal, s1 Max shear stress, tmax VERIFY FEA RESULTS WITH HAND CALCS!!!! Verify Principal Stresses with Hand Calculations or Mohr’s Circle!! Thrust Load = 8,000 to 10,000 lb Torsion Load= 300 lb-ft HOT SPOT! y x HAND CALCS: sy t xy P 8,000lbs 23,895 psi A (0.88in) 2 (0.59in) 2 4 From Axial Load (Compression) Tc 3,600lbin(0.44in) 33,720 psi J [(0.44in) 4 (0.295in) 4 ] 2 From Torque s y 23,895 psi s x 0 psi t xy 33,720 psi HAND CALCS Cont’d: Principal Stresses: s 1, 2 s x s y 2 s x s y t xy2 / 2 2 =-11.95 +/- 35.8 ksi 0 23.895 0 23.895 2 / 33.720 2 2 2 s1 23.85ksi s x s y t xy2 35.8 ksi t max 2 2 s 2 47.75ksi How do these values compare with FEA results? Next: use Mohr’s circle to resolve