Subpart L Scaffolds

advertisement

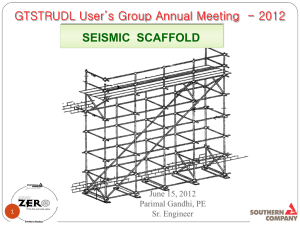

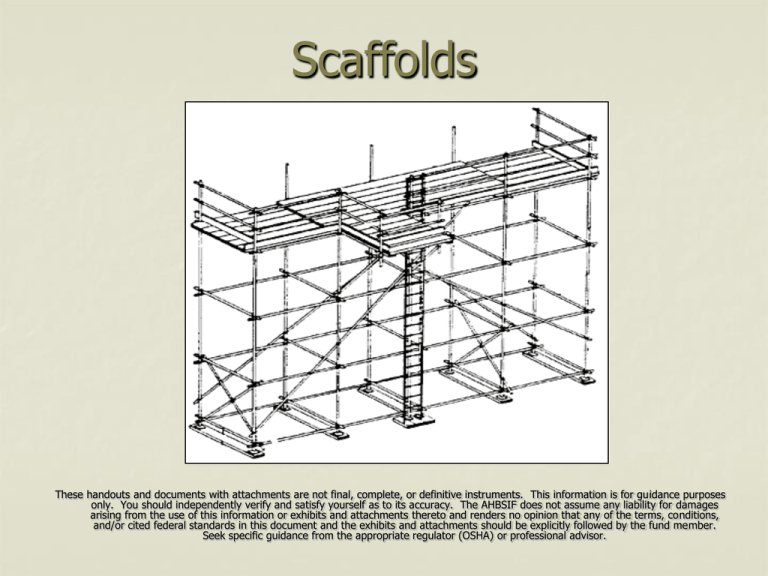

Scaffolds These handouts and documents with attachments are not final, complete, or definitive instruments. This information is for guidance purposes only. You should independently verify and satisfy yourself as to its accuracy. The AHBSIF does not assume any liability for damages arising from the use of this information or exhibits and attachments thereto and renders no opinion that any of the terms, conditions, and/or cited federal standards in this document and the exhibits and attachments should be explicitly followed by the fund member. Seek specific guidance from the appropriate regulator (OSHA) or professional advisor. Introduction to Scaffolds OSHA revised the scaffold standard in 1997 due to the following; A quarter of the workers responsible for installing work platforms and inspecting, and assembling them had no formal training. Only 1/3 of scaffolds were equipped with handrails. Defining a Competent Person One who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to eliminate them. Scaffolds shall be constructed, altered, or dismantled under the supervision of a competent person. General Requirements All scaffolds must be inspected prior to use. 10’ is the point at which some means of fall protection must be used. Top handrails should be around 42”, with the mid-rail about half way at 21”. Toe boards or other adequate means of falling object protection must be installed if there is a possibility of anything falling and striking someone below. General Requirements All scaffolds must support their own weight and 4x the maximum intended load. Vertical tie-in or outrigger support is not necessary on a free-standing scaffold until the height exceeds the minimum dimension of the base by four times. General Requirements Ladder use on a scaffold is prohibited. Platforms must be kept clear of debris. Do not load side brackets. Most are rated at 25 lbs/ft² maximum. Decks And Planking All platforms must be fully decked or planked. Each abutted end of a plank shall rest on a separate support surface. Overlap platforms not less than 12” only over supports, unless restrained to prevent movement, i.e. ”Cleating”. The working deck should never be more than 14” away from the working surface. Decks And Planking A scaffold grade plank will be stamped or marked as such Plank must be laminated or solid drawn A lumber yard 2 x 10 can be used if it is free of knots or other defects Rough Sawn, Full Dimension Lumber Nominal Thickness Lumber Working Load in lbs/ft² 25 50 75 25 50 75 Permissible Span in Feet 10 8 6 8 6 6 Overhead Power Lines The clearance between scaffolds and power lines is as follows: Insulated Lines Minimum Distance < 300 V 3’ 300 to 50 kV 10’ > 50 kV 10’ + 1/2” for every additional kV Uninsulated Lines Minimum Distance < 50 kV 10’ > 50 kV 10’ + 1/2” for every additional kV Frame Scaffolds Systems should use only original parts. Components from different systems should not be mixed. All frame scaffolds must use a manufactured base pad. Vertical tubes should never sit directly on the ground or makeshift mud sill. X-braces may serve as a toprail or mid-rail, but not both. If aluminum walking decks are used, be sure that end hooks are in place and that the dimensions match the scaffold. Frame Scaffolds - Access OK for Climbing Must have External Access Ladder Frame Walk-Through Frame Scaffolds - Access Erectors can climb either type, but provisions for safe access should be established as soon as possible. Bottom rung cannot be more than two feet high. Options for access are manufactured bolt-on ladder system, stair system, or extension ladder secured and sloped properly. X-braces are not intended for use as access. “Stick-Built” Pole Scaffold 2” x 4” poles free of knots, splits or other defects. 1” x 4” cross-bracing for each section. 2” x 6” or 2” x 8” block under pole if soft ground. Walk board a minimum 2” x 10” free of knots or other defects. Walk boards must hang over bearer a minimum of 6”.Walk boards must overlap each other a minimum of 12”. 2” x 4” top rail, mid rail, and toe board Stick Built Scaffolds Proper overlap on deck planking Top rail and mid rail established after deck height reaches ten feet Adequate support between stanchions Proper mud sills under poles Is this scaffold complete? Pump Jack Scaffolds Pump Jack brackets, braces, and accessories must be fabricated from metal. Each pump jack bracket must have two positive gripping mechanisms. Poles should be secured to the structure with triangular bracing. Work benches should not be used as a working deck. If 2x4’s are spliced to make a pole, mending plates must be installed to maintain strength. Ladder Jack Scaffolds Platforms must not exceed 20’ in height. Job made ladders cannot be used to support ladder jack scaffolds. Ladders that support ladder jacks must be placed, fastened, or equipped with devices to prevent slipping. Scaffold platforms must not be bridged to one another. Werner and Louisville produce handrail systems for ladder jack working decks. Trestle Ladder Scaffold Scaffold platforms must be placed no higher than the second-highest rung of the ladder A conventional step ladder is not to be used for this scaffold configuration Work platforms must be secure All general scaffold and ladder standards apply Carpenters Bracket Scaffold Typically constructed of wood Each piece must be properly fitted and securely joined Brackets must be no more than 8 ft. apart The platform can be no less than two 2’ x 10’ size planks Attachment must occur in one of following ways: Hook over a well secured and strong supporting member A bolt of no less than 5/8” diameter extended through the inside of the building wall Unit attaches via metal stud or welding if possible Hanging Scaffold System The Wall Walker Device meets OSHA standards It can be hung on the inside or outside of the wall Fall protection attachments are available The horizontal beam positional is adjustable The Wall Walker General Framing, exterior face hanging on top plate Handrail System in place Setting pre-fab trusses Aluminum walk deck locked into place The Wall Walker Cutting tails on rafters Using inside wall position from top plate Easy stow and carry Unit folds down, handrail post stores inside vertical support Wall Walker Hardware Mid Wall Bracket Hand Rail Brackets Stabilizer Bar Manually Propelled Mobile Scaffolds Also known as a “Perry” or “Baker” scaffold. The casters and wheels must be locked to prevent movement while the scaffold is stationary. An employee may ride this scaffold under the following conditions: The floor is level and free of all obstructions The minimum dimension of the scaffold base is at least half the height The wheels are equipped with rubber or some other resilient material All tools and materials are secured or removed prior to movement Because the wheels and castors must be locked once the scaffold is set, this prohibits movement from being a one-man operation. Rustgo Manual Work Platform All-terrain motorless work platform with rear steering capabilities Can be towed to jobsite location on a standard hitch Winch system on each upright raises and lowers work platform Front handrail system is completely removable Employees cannot stay on work platform during movement All general scaffold standards apply Horse Scaffolds Members Horizontal Bearer Legs Dimensions 3 x 4” 11/4” x 41/2” Braces between Legs 1 x 6” Gusset Brace at top of Legs 1 x 8” Half Diagonal Braces 11/4 x 41/2” Horses must be spaced not more than 5 ft. for medium duty, not more than 8 ft. for light duty For stacking applications, must not exceed two tiers or ten feet in height Horses must be inspected for defects prior to use All general scaffold standards apply Adjustable Scaffolds Use is more common to commercial projects Pre-shift inspection of all components is critical Hoist Motors Outriggers All Fastening Points All general scaffold standards apply Crawling Boards / Chicken Ladders Crawling board must be at least 10” wide and 1” thick Cleats Must be at least 1” x 11/2” Must be as long as the board is wide Must be spaced equally at no more than 2’ apart If the crawling board presents a fall exposure, fall protection must be used i.e. handrails-harness Scissor Lifts Scissor lifts are not addressed by the aerial lift provisions of Subpart L. There are no OSHA provisions that address scissor lifts, however, employers must comply with the applicable provisions of Subpart L, both general and specific. Example: Scissor lifts are mobile, the specific requirements for mobile scaffolds standard (§1926.452 (w) - mobile scaffolds) shall be used. Scissor lifts do not require a personal fall arrest system for occupants. Aerial Lifts Occupants of an aerial lift must use a personal fall arrest system. Occupants are required to stay on the floor of the basket at all times. Pre-shift inspection is critical to insure safe operation. The lift may not be field modified without the manufacturers consent. Scaffold Checklist Stability of the ground or work surface, proper mud sills when needed All components from the same manufacturer Adjustable screw jacks with base pads in every post External ladder access for steel scaffold bucks not designed for climbing Erection, dismantle, alteration done under supervision of a competent person Complete decking from front to back on all working levels Fall protection in place once work deck reaches or exceeds 10 ft. for conventional scaffolds Daily inspection performed by a competent person before and during the shift Scaffold must be designed to hold four times the intended working load (safety factor of “4”) Tie-ins set once the height of the scaffold exceeds four times the minimum base dimension Scaffold grade planking or better for all work surfaces Planks overlapped over horizontal support no less than 12” Overhead protection for other trades or personnel below Pre-shift inspection of all motorized components, proper PPE in use