3 - WordPress.com

advertisement

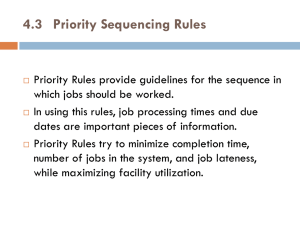

SHCEDULLING (PART II) GROUP MEMBERS: HAMIZAH BINTI HAMZAH B050910232 NORAINA BINTI MOHD YUSOF B050910140 NUR ADILA BINTI RAMLI B050810 SEQUENCING THEORY FOR SINGLE MACHINE 1. 2. 3. 4. 5. FCFS SPT EDD CR ALGORITHM - Moore 1968 - Lawler’s Example:FCFS FCFS (first come-first served) Jobs are processed in the sequence in which they entered the shop The simplest and nature way of sequencing as in queuing of a bank Example. 1 A machine center in a job shop for a local fabrication company has five unprocessed jobs remaining at a particular point in time. The jobs are labeled 1, 2, 3, 4, and 5 in the order that they entered the shop. The respective processing times and due dates are given in the table below. Sequence the 5 jobs by above 4 rules and compare results based on mean flow time, average tardiness, and number of tardy jobs Mean Flow time=268/5=53.6 Average tardiness=121/5=24.2 No. of tardy jobs=3 Example:SPT SPT (shortest processing time) Jobs are sequenced in increasing order of their processing time The job with shortest processing time is first, the one with the next shortest processing time is second, and so on Mean Flow time=135/5=27.0 Average tardiness=43/5=8.6 No. of tardy jobs=1 Example: EDD EDD (earliest due date) Jobs are sequenced in increasing order of their due dates The job with earliest due date is first, the one with the next earliest due date is second, and so on Mean Flow time=235/5=47.0 Average tardiness=33/5=6.6 No. of tardy jobs=4 Example: Scheduling CR CR (Critical ratio) Critical ratio is the remaining time until due date divided by processing time; Scheduling the job with the smallest CR next; Current time: t=0 Job number Processing Time 1 11 2 29 3 31 4 1 5 2 Due Date 61 45 31 33 32 Critical Ratio 61/11(5.545) 45/29(1.552) 31/31(1.000) 33/1 (33.00) 32/2 (16.00) Current time should be reset after scheduling one job Current time: t=31 Job number Processing Time 1 2 4 5 11 29 1 2 Current time=60 (31+29) Job number Processing Time 1 4 5 11 1 2 Due Date-Current Time Critical Ratio 30 14 2 1 Due DateCurrent Time 1 -27 -28 30/11(2.727) 14/29(0.483) 2/1 (2.000) 1/2 (0.500) Critical Ratio 1/11(0.0909) -27/1<0 -28/2<0 Both Jobs 4 and 5 are later, however Job 4 has shorter processing time and thus is scheduled first; Finally, job 1 is scheduled last. Job number 3 2 4 5 1 Totals Processing Time 31 29 1 2 11 Mean Flow time=289/5=57.8 Average tardiness=87/5=17.4 No. of tardy jobs=4. Completion Time 31 60 61 63 74 289 Tardiness 0 15 28 31 13 87 Sequencing Rules Summary Rule Mean Flow Time Average Tardiness Number of Tardy Jobs FCFS SPT EDD CR 53.6 27.0 47.0 57.8 24.2 8.6 6.6 17.4 3 1 4 4 Discussions SPT results in smallest mean flow time; EDD yields the minimum maximum tardiness (42, 43, 18, and 31 for the 4 different rules); Always true? Yes! Sequencing Theory for A Single Machine AN ALGORITHM (Moore 1968) Minimizing the number of Tardy Jobs that minimizes the number of tardy jobs for the single machine problem. Step1. Sequence the jobs according to the earliest due date to obtain the initial solution. That is d[1] d[2],…, d[n]; Step2. Find the first tardy job in the current sequence, say job [i]. If none exists go to step 4. Step3. Consider jobs [1], [2], …, [i]. Reject the job with the largest processing time. Return to step2. (Why ?) Reason: It has the largest effect on the tardiness of the Job[i]. Step4. Form an optimal sequence by taking the current sequence and appending to it the rejected jobs. (Can be appended in any order?) Yes, because we only consider the number of tardiness jobs rather than tardiness. Sequencing Theory for A Single Machine Example Job 1 2 3 4 5 6 Due date 15 6 9 23 20 30 Processing time 10 3 4 8 10 6 Longest processing time Solution Job 2 3 1 5 4 6 Due date 6 9 15 20 23 30 Processing time 3 4 10 10 8 6 Completion 3 7 17 27 35 41 time Sequencing Theory for A Single Machine Example :Solution (Cont.) Longest processing time Job 2 3 5 4 6 Due date 6 9 20 23 30 Processing time 3 4 10 8 6 Completion time 3 7 17 25 31 Job 2 3 4 6 Due date 6 9 23 30 Processing time 3 4 8 6 Completion time 3 7 15 21 The optimal sequence: 2, 3, 4, 6, 5, 1 or 2, 3, 4, 6, 1, 5. In each case the number of tardy jobs is exactly 2. Sequencing Theory for A Single Machines Precedence constraints: Lawler’s Algorithm Example Job 1 2 3 4 5 6 Processing time 2 3 4 3 2 1 Due date 3 6 9 7 11 7 Example Step1: find the job scheduled last (sixth) Not predecessor Job 1 2 3 4 5 6 Processing time 2 3 4 3 2 1 Due date 3 6 9 7 11 7 τ =2+3+4+3+2+1=15 Tardiness 3 5 6 15-9=6 15-11=4 15-7=8 Step2: find the job scheduled fifth Not predecessor Job 1 2 3 4 6 Processing time 2 3 4 3 1 Due date 3 6 9 7 7 τ =15-2=13 Tardiness 3 6 13-9=4 13-7=6 Example Not predecessor Step3: find the job scheduled fourth Job 1 2 4 6 Processing time 2 3 3 1 Due date 3 6 7 7 τ =13-4=9 Tardiness Because job3 is no longer on the list, Job 2 now because a candidate. 2 6 9-6=3 9-7=2 Step4: find the job scheduled third Not predecessor Job 1 2 4 Processing time 2 3 3 Due date 3 6 7 τ =9-1=8 Tardiness Because job6 has been scheduled, Job 4 now because a candidate along with Job 2. 2 4 8-6=2 8-7=1 Example 3 Step5: find the job scheduled second Job 1 2 4 6 3 5 Job 1 2 Processing time 2 3 Due date 3 6 Not predecessor The optimal sequence: 1-2-4-6-3-5 Processing time Flow time Due date Tardiness 2 3 3 1 4 2 2 5 8 9 13 15 3 6 7 7 9 11 0 0 1 2 4 4 Maximum tardiness SEQUENCING THEORY FOR MULTIPLE MACHINE Sequencing Theory for Multiple Machines 1. n jobs are to be process through m machine Assume that n jobs are to be processed through m machines. The number of possible schedules is astonishing, even for moderate values of both n and m. For each machine, there is n! different ordering of the jobs; if the jobs may be processed on the machines in any order, there are totally (n!)m possible schedules. (n=5, m=5, 25 billion possible schedules) Let’s consider a case when each job must be processed in the following order First on machine 1, then machine 2…. Sequencing Theory for Multiple Machines Suppose that two jobs,Y and Z, are to be scheduled on two machines, 1 and 2, the processing times are Machine 1 Machine 2 Job Y Job Y Job Y Job Z Job Z Job Z Assume that both jobs must be processed first on machine A and then on machine B. There are four possible schedules. Sequencing Theory for Multiple Machines Schedule Total flow time Mean flow time Mean idle time 1 11 (6+11)/2=8.5 (5+5)/2=5 2 7 6.5 1 3 12 9.5 6 4 12 11.5 6 Deterministic Scheduling with Multiple Machines: Johnson’s Rule Name Machine 1 = A, Machine 2 = B, then ai = processing time for job i on A and bi = processing time for job i on B Johnson’s Rule says that job i precedes job j in the optimal sequence if min ai , b j min a j , bi Algorithm: Step 1: Record the values of ai and bj in two columns Step 2: Find the smallest remaining value in two columns. If this value in column a, schedule this job in the first open position in the sequence; if this value in column b, schedule this job in the last open position in the sequence; Step 3: Cross off each job as it is scheduled Sequencing Theory for Multiple Machines Job Example 1: Machine A 1 2 3 4 5 job A B 1 5 2 2 1 6 3 9 7 4 3 8 5 10 4 Machine B 5 1 9 3 10 2 6 7 8 4 Johnson’s schedule: 2 –> x –> x –> x –> x 2 –> x –> x –> x –> 1 2 –> x –> x –> 5 –> 1 2 –> 4 –> x –> 5 –> 1 2 –> 4 –> 3 –> 5 –> 1 Optimal sequence : 2 4 3 5 1 job A B 1 5 2 2 1 6 3 9 7 4 3 8 5 10 4 Optimal sequence : 2 4 3 5 1 Sequencing Theory for Multiple Machines 2. Extension to Three Machines The three-machine problem can be reduced to a two-machine problem if the following condition is satisfied min Aimax Bi or min Cimax Bi It is only necessary that either one of these conditions be satisfied. If that is the case, then the problem is reduced to a two-machine problem Define Ai’=Ai+Bi, Bi’=Bi+Ci Solve the problem using the rules described above for two-machines, treating Ai’ and Bi’ as the processing times. The resulting permutation schedule will be optimal for the three-machine problem. If the condition are not satisfied, this method will usually give reasonable, but possibly sub-optimal results. Sequencing Theory for Multiple Machines 3. The Two-Job Flow Shop Problem: assume that two jobs are to be processed through m machines. Each job must be processed by the machines in a particular order, but the sequences for the two jobs need not be the same. Graphical procedure developed by Akers (1956): Draw a Cartesian coordinate system with the processing times corresponding to the first job on the horizontal axis and the processing times corresponding to the second job on the vertical axis. Block out areas corresponding to each machine at the intersection of the intervals marked for that machine on the two axes. Determine a path from the origin to the end of the final block that does not intersect any of the blocks and that minimizes the vertical movement. Movement is allowed only in three directions: horizontal, vertical, and 45-degree diagonal. The path with minimum vertical distance corresponds to the optimal solution. Sequencing Theory for Multiple Machines Example 2: A regional manufacturing firm produces a variety of household products. One is a wooden desk lamp. Prior to packing, the lamps must be sanded, lacquered, and polished. Each operation requires a different machine. There are currently shipments of two models awaiting processing. The times required for the three operations for each of the two shipments are Job 1 Job2 Operation Time Operation Time Sanding (A) 3 A 2 Lacquering (B) 4 B 5 Polishing( C ) 5 C 3 Minimizing the flow time is the same as maximizing the time that both jobs are being processed. That is equivalent to finding the path from the origin to the end of block C that maximizes the diagonal movement and therefore minimizes either the horizontal or the vertical movement. or 10+6=16 or 10+(3+2)=15 15 14+2+2=18 14 C 13 C 12 Example 3: F 11 10 B 14+4=18 B 9 Job 1 8 7 6 D 5 D 4 3 2 A A 1 0 0 1 2 B J1 B J2 A 3 4 D5 6 7 C8 D 10 11 12 13 14 15 16 17 A D A C D B 7 J1 B J2 A 9 11 D B C 15 A C C 18 Job2 Order & Operation B Time Time 3 Order & Operation A D 4 D 5 C 2 B 4 A 5 C 3 2 LINE BALANCING WHAT IS LINE BALANCING??? EVERYONE IS DOING THE SAME AMOUNT OF WORK DOING THE SAME AMOUNT OF WORK TO CUSTOMER REQUIREMENT VARIATION IS “SMOOTHED” NO ONE OVERBURDENED NO ONE WAITING EVERYONE WORKING TOGETHER IN A BALANCED FASHION Example 6 The Final assembly of NANO personal computers, a generic mailorder PC clone, requires a total of 12 tasks. The assembly is done at the Lubbock, Texas, plant using various components imported from the Far East. The network representation of this particular problem is given in the following figure. ti=70, and the production rate is a unit /15 minutes; The minimum number of workstations = [70/15]=5 The job times and precedence relationships for this problem are summarized in the table below. Task Immediate Predecessors Time 1 2 3 4 5 6 7 8 9 10 11 12 _ 1 2 2 2 2 3, 4 7 5 9, 6 8, 10 11 12 6 6 2 2 12 7 5 1 4 6 7 The solution precedence requires determining the positional weight of each task. The positional weight of task i is defined as the time required to perform task i plus the times required to perform all tasks having task i as a predecessor. t3+t7+t8+t11+t12=31 The ranking 1, 2, 3, 6, 4, 7, 5, 8, 9, 10, 11, 12 Task Positional Weight 1 2 3 4 5 6 7 8 9 10 11 12 70 58 31 27 20 29 25 18 18 17 13 7 PROFILE 1: C=15 Station 1 2 3 4 5 6 Tasks 1 2, 3, 4 5, 6, 9 7, 8 10, 11 12 Processing time 12 14 15 12 10 7 Idle time 3 1 0 3 5 8 Task Immediate Predecessors Time 1 _ 12 2 3 4 5 6 7 8 9 10 11 12 1 2 2 2 2 3, 4 7 5 9, 6 8, 10 11 6 6 2 2 12 7 5 1 4 6 7 The ranking 1, 2, 3, 6, 4, 7, 5, 8, 9, 10, 11, 12 PROFILE 1: C=15 Station 1 2 3 4 5 6 Tasks 1 2,3,4 5,6,9 7,8 10,11 12 Processing time 12 14 15 2 10 7 Idle time 3 1 0 3 5 8 15 Cycle Time=15 T1=12 T2=6 T5=2 T7=7 T10=4 T12=7 T3=6 T6=12 T8=5 T11=6 T4=2 T9=1 T10=4 T12=7 The ranking 1, 2, 3, 6, 4, 7, 5, 8, 9, 10, 11, 12 Evaluate the balancing results by the efficiency ti/NC; The efficiencies for Profiles 1 is 77.7%. Profile 2: Increasing cycle time from 15 to 16 Alternative 1: Change cycle time to ensure 5 station balance Station 1 2 3 4 5 Tasks 1 2,3,4,5 6,9 7,8,10 11,12 Idle time 4 0 3 0 3 Increasing the cycle time from 15 to 16, the total idle time has been cut down from 20 min/units to 10; resulting in a substantial improvement in balancing rate. However, the production rate has to be reduced from one unit/15 minutes to one unit/16minute; Profile 3: C=13 Alternative 2: Staying with 6 stations, see if a six-station balance could be obtained by cycle time less that 15 minutes Station 1 2 3 4 5 6 Tasks 1 2,3 6 4,5,7,9 8,10 11,12 Idle time 1 1 1 1 4 0 The efficiencies for profile 1~ 3 are 77.7%, 87.5%, and 89.7%. Thus the profile 3 is the best one. 13 minutes appear to be the minimum cycle time with six station balance. Increasing the number of stations from 5 to 6 results in a great improvement in production rate;