What to do when you donot have a clue

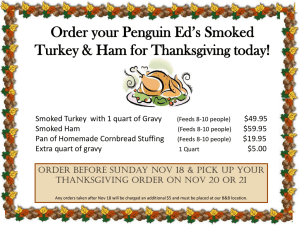

advertisement

What to do when you don’t have a clue. Terry A. Ring Chemical Engineering University of Utah First Job • MS ChE at UC Berkeley, BS ChE Clarkson – Well Educated in traditional unit operations • 1st Project Develop Mass and Energy Balance for Alumina from clay Acid Leach process using a computer before ASPEN exists • 2nd Project Al2O3 Nodules Shaft Kiln 1800C Dryer 200C Hot Hot Gas 2nd Project • Rotating Pan Nodulizer for Al2O3 – – – – – • Control Pellet Size Minimize Dust Generated Minimize water Used Minimize additives Used Minimize Pore Volume Process Variables – Pan (1 m pilot, 5 m plant) • • • • • RPM of Pan Pan Angle Spray Configuration Alumina feed point Ratio of Alumina to water fed – Conveyor Dryer • • Drying Temperature Airflow – Shaft Kiln • • • Sintering Temperature Holding Time Project finished in 6 mo. Project 3 • Found Synergism between additives – Decreased time/energy needed to sinter by ½ – Lowered Operating costs to produce • US Patent 4,045,234 “Process For Producing High Density Sintered Alumina” • $1 million (1974 $s) in fuel savings ($4.83 million 2013 $s) • How much was I paid for this work? Getting Started • Call Plant and Talk to Engineer – Did not really know much – Relies on Operator to run Pan Nodulizer • Call Plant and Talk to Operator – Everything controls Everything • Call Technician who rate the Pilot Plant – Water and pan angle and RPM control nodule size • Literature Search – 1 paper - P. Somasundaran and D. Feustenau – 1 PhD thesis - P. Somasundaran and D. Feustenau Fm (x,t) – Cumulative Mass Distribution P. Somasundaran and D. Feustenau Fm ( x , t ) t 1 (t ) x s0 with boundary Fm ( x , t ) 0 a (s, u ) u xs u x Fm ( u , t ) x Fm ( s , t ) Agglomerat conditions at x 0, Fm ( x , t ) 1 and initial condition Fm ( x , t ) Fm ,o ( x ) at t 0 at x ion What to do? • • • • Short Time for the Project – 6 months No ChE Background that is useful! No literature that is useful! No people to help! • So complain at lunch to fellow employees Design of Experiments • Lunch Companion – I think you might try statistically designed experiments or design of experiments – We had a consultant come to talk about this two years before you joined the company. – I do not know much about what the consultant said. • Corporate Librarian Saved Me Other Names • • • • Statistically Designed Experiments Design of Experiments Factorial Design of Experiments ANOVA – Analysis of variance : A mathematical process for separating the variability of a group of observations into assignable causes and setting up various significance tests. Comparison I Design of Experiments Traditional Experimentation • Tests – Theory – Correlation • Develop a new – Theory – Correlation • End up with a mathematical understanding of experimental results based on process variables Comparison I Design of Experiments • Determines if Process Variables are important (significant ) – compared to experimental errors • Develops a mathematical relationship for experimental results based upon process variables – No Theory is developed or tested • • • Allows Predictions of Results for all process variables within ranges used in experimentation Allows Process Optimizations Understand the requirements on processing conditions needed to meet production specifications Traditional Experimentation • Tests Theory • Develop a new Theory • End up with a mathematical understanding of experimental results How is this approach different? Design of Experiments Traditional Experimentation • Do a series of experiments changing one variable at a time • 5 Process Variables (PV) • • • • • RPM of Pan Pan Angle Spray Configuration Alumina feed point Ratio of Alumina to water fed • 4 different values for PV • Number of Experiments – 5^4= 625 experiments – 2 experiments/day ~ 1 yr work How is this approach different? Design of Experiments Traditional Experimentation • Do a series of experiments changing all variables at the same time • 5 Process Variables (PV) • Do a series of experiments changing one variable at a time • 5 Process Variables (PV) • • • • • RPM of Pan Pan Angle Spray Configuration Alumina feed point Ratio of Alumina to water fed • 2 levels for PV plus multiples of center point • Number of Experiments – 25+1= 64 experiments – 2 experiments/day ~ 1 month work • • • • • RPM of Pan Pan Angle Spray Configuration Alumina feed point Ratio of Alumina to water fed • 4 different values for PV • Number of Experiments – 54= 625 experiments – 2 experiments/day ~ 1 yr work Different Nomenclature • Effects of PVs – Process Variables • • • • • • Scaled PVs ( -1 to +1) – • • original X value and converts to (X − a)/b, where a = (Xh + XL)/2 and b = (Xh−XL)/2 Effect Ei = [Σ Ri (+) – Σ Ri (-) ]/N Responses, R’s – – – – – • • RPM of Pan Pan Angle Spray Configuration Alumina feed point Ratio of Alumina to water fed Diameter of Nodules Water Content of Nodules Pore Volume Dust in Dryer Sintering Temperature Variance (StDEV2) Software – Stat-ease, MiniTab • Response Surface • Ri = E1 X1 + E2 X2 + E3 X3+ … +E11 X12 + E22 X22 + E33 X32 + … +E12 X1 X2 + E13 X1 X3 + E23 X2 X3 + … +E123 X1 X2 X3 Response Surface Map Bleaching Cotton • Effects (PVs) – – – – % NaOH %H2O2 Temp Time • Responses – Reflectance – Fluidity • > 6 to be useful Steps for DOE • Identify process variables – • Identify the range for each process variable – – • • Often more PVs than you initially think are important High Low Scale Process Variables Set up experimental matrix • • • • • • Randomize Experiments Identify Responses to be measured for each process variable Run Experiments Analyze Experimental results using ANOVA Compare responses to experimental uncertainty (F-test) – • • • (+,-,-), (+,+,-),(+,-,+), (+,+,+) Remove insignificant process variables Calculate Response mathematics Ri = E1 X1 + E2 X2 + E3 X3+ … +E11 X12 + E22 X22 + E33 X32 + … +E12 X1 X2 + E13 X1 X3 + E23 X2 X3 + … +E123 X1 X2 X3 Use for Process Optimization Use for 6-sigma – Identify the range that a PV can vary and keep product within specification Nodulizer Results • Nodule Diameter – Important Effects (in order of importance) • Water to alumina ratio • RPM • Pan angle • Dust Production – Important Effects (in order of importance) • Water to alumina ratio • Additive concentration • RPM Results • Sintered Density – Important Effects • • • • Sintering Time Pan RPM Water to alumina ratio Additives • Water Control is Critical • IR water sensor and control system story