Assembly line balancing

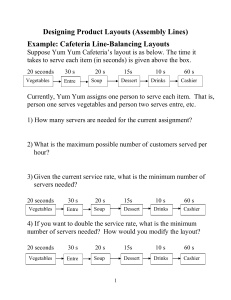

advertisement

Dr. Ron Lembke ASSEMBLY LINE BALANCING ASSEMBLY-LINE BALANCING Situation: Assembly-line production. Many tasks must be performed, and the sequence is flexible Parts at each station same time Tasks take different amounts of time How to give everyone enough, but not too much work for the limited time. PRODUCT-ORIENTED LAYOUT Operations Belt Conveyor PRECEDENCE DIAGRAM Draw precedence graph (times in minutes) A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LEGAL ARRANGEMENTS A B G 5 20 E C D 5 10 8 F 15 H I 12 J 7 12 3 Ok: AC|BD|EG|FH|IJ ABG|CDE|FHI|J NOT ok: BAG|DCH|EFJ|I DAC|HFE|GBJ|I C|ADB|FG|EHI|J LEGAL ARRANGEMENTS B A G 5 20 15 E C D 5 10 CT = maximum of workstation times 8 H F I 12 J 7 12 3 AC|BD|EG|FH|IJ = max(25,15,23,15,19) = 25 ABG|CDE|FHI|J = max(40,23,27,7) = 40 C|ADB|FG|EHI|J = max(5,35,18,32,7) = 35 AC BD EG FH IJ CYCLE TIME The more units you want to produce per hour, the less time a part can spend at each station. Cycle time = time spent at each spot C= Production Time in each day Required output per day (in units) C = 800 min / 32 = 25 min 800 min = 13:20 NUMBER OF WORKSTATIONS Given required cycle time, find out the theoretical minimum number of stations Nt = Sum of task times (T) Cycle Time (C) Nt = 97 / 25 = 3.88 = 4 (must round up) ASSIGNMENTS Assign tasks by choosing tasks: with largest number of following tasks OR by longest time to complete Break ties by using the other rule NUMBER OF FOLLOWING TASKS Nodes # after C 6 D 5 A 4 B,E,F 3 G,H 2 I 1 Choose C first, then, if possible, add D to it, then A, if possible. A 20 C 5 B G 5 D 10 E 15 8 H F 3 12 I 12 J 7 PRECEDENCE DIAGRAM Draw precedence graph (times in seconds) A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 NUMBER OF FOLLOWING TASKS Nodes # after A 4 B,E,F 3 G,H 2 I 1 A B E C D 5 10 B, E, F all have 3 stations after, so use tiebreaker rule: time. B=5 E=8 F=3 Use E, then B, then F. G 5 20 A could not be added to first station, so a new station must be created with A. 8 F 3 15 H 12 I 12 J 7 PRECEDENCE DIAGRAM E cannot be added to A, but E can be added to C&D. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 PRECEDENCE DIAGRAM Next priority B can be added to A. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 PRECEDENCE DIAGRAM Next priority B can be added to A. Next priority F can’t be added to either. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 NUMBER OF FOLLOWING TASKS Nodes # after G,H 2 I 1 G and H tie on number coming after. G takes 15, H is 12, so G goes first. PRECEDENCE DIAGRAM G can be added to F. H cannot be added. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 PRECEDENCE DIAGRAM I is next, and can be added to H, but J cannot be added also. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 PRECEDENCE REQUIREMENTS B A G 5 20 15 E C D 5 10 8 H F 12 3 Why not put J with F&G? AB CDE HI FG J I 12 J 7 CALCULATE EFFICIENCY We know that at least 4 workstations will be needed. We needed 5. Efficiencyt = Sum of task times (T) Actual # WS * Cycle Time = 97 / ( 5 * 25 ) = 0.776 We are paying for 125 minutes of work, where it only takes 97. LONGEST FIRST Try choosing longest activities first. A is first, then G, which can’t be added to A. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST H and I both take 12, but H has more coming after it, then add I. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST D is next. We could combine it with G, which we’ll do later. E is next, so for now combine D&E, but we could have combined E&G. We’ll also try that later. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST J is next, all alone, followed by C and B. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST F is last. We end up with 5 workstations. A B G 5 20 E C D 8 5 10 F 3 15 I H CT = 25, so efficiency is again Eff = 97/(5*25) = 0.776 12 12 J 7 LONGEST FIRST- COMBINE E&G Go back and try combining G and E instead of D and E. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST- COMBINE E&G J is next, all alone. C is added to D, and B is added to A. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST- COMBINE E&G F can be added to C&D. Five WS again. CT is again 25, so efficiency is again 0.776 A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST - COMBINE D&G Back up and combine D&G. No precedence violation. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST - COMBINE D&G Unhook H&I so J isn’t stranded again, I&J is 19, that’s better than 7. E&H get us to 20. This is feeling better, maybe? A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 LONGEST FIRST - COMBINE D&G 5 Again! CT is again 25, so efficiency is again 97/(5*25) = 0.776 A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 CAN WE DO BETTER? A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 CAN WE DO BETTER? If we have to use 5 stations, we can get a solution with CT = 20. A B G 5 20 15 E C D 5 10 I J 12 7 8 H F 3 12 CALCULATE EFFICIENCY With 5 WS at CT = 20 Efficiencyt = Sum of task times (T) Actual # WS * Cycle Time = 97 / ( 5 * 20 ) = 0.97 We are paying for 100 minutes of work, where it only takes 97. OUTPUT AND LABOR COSTS With 20 min CT, and 800 minute workday Output = 800 min / 20 min/unit = 40 units Don’t need to work 800 min Goal 32 units: 32 * 20 = 640 min/day 5 workers * 640 min = 3,200 labor min. We were trying to achieve 4 stations * 800 min = 3,200 labor min. Same labor cost, but more workers on shorter workday HANDLING LONG TASKS Long tasks make it hard to get efficient combinations. Consider splitting tasks, if physically possible. If not: Parallel workstations use skilled (faster) worker to speed up SUMMARY Compute desired cycle time, based on Market Demand, and total time of work needed Methods to use: Largest first, most following steps, trial and error Compute efficiency of solutions A shorter CT can sometimes lead to greater efficiencies Changing CT affected length of work day, looked at labor costs