Patient Value Statement

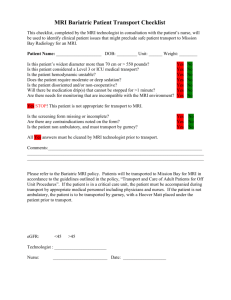

advertisement

MRI Process Improvement by Tyler Speck, Administrative Director, Medical Imaging Program HSN MRI – Prior to PIP • MRI service operational for over 12 years • Fully compliant with MIS standards (Management Information System) • Productivity level in excess of 140% (based on MIS standards) • Below the 50% percentile (good) in benchmarking • Routinely fielding calls from peer hospitals asking how we achieve productivity performance Provincial MRI Lean Project - 2011 • Ministry of Health requested all MRIs in the province go through a LEAN Process Improvement Project to maximize limited resources • Performance of MRIs inconsistent across the province • Ministry wanted to improve access to MRI services for patients • HSN MRI considered top efficiency performer Provincial MRI Lean Project - 2011 Project Objectives: • To positively impact MRI wait times by optimizing existing resources while providing patient centered care • To create a commitment to continuous improvement Project Structure PreEngagement (6 weeks) Initial Assessment (1 week) Process Diagnosis (2 weeks) Process Optimization (7 weeks) Evaluation (18 weeks) Identify & engage key leadership Identify & engage key stakeholders Collaboratively analyze current value stream Analyze time allocation & revise scheduling template Monitor impact & feasibility of new processes Data Sharing Agreement Conduct interviews & observations Establish targets for key performance metrics Collectively identify bottlenecks within processes Iterative solution development Memorandum of Understanding Analyze quantitative data Define desired future processes Identify & prioritize opportunities for process improvement Monitor compliance with new processes Provide Lean and best practices training Analyze quantitative data Develop & trial solutions Monitor key performance indicators & take action as required Kick Off Training August 2011 September 27, 2011 Value Stream Mapping Rapid Improvement Event Final Evaluation Data, Data, Data February 2012 October 11-13, 2011 October 31-November 2, 2011 Schedule Optimization Workshop November 21-22, 2011 7 Metrics and Targets • One of the principles of the Lean approach is evidence-based decision-making. MRI PIP stresses the importance of using evidence to identify improvement opportunities, as well as the importance of performance measures to assess the success of newly implemented processes. • The hospital team identified outcome measures as indicators for monitoring change and identifying opportunities for improvement. For each of these indicators, baseline levels were calculated and targets were established as a projection of what the site would like to achieve. Patient Value Statement and Business Case One of the main principles of the MRI PIP approach is the importance of the patient's perspective. The team therefore developed a patient value statement that summarizes the value they hope to provide to the patient from implementing new and improved processes. Patient Value Statement: My MRI exam will be completed in a timely manner. The environment will be comfortable, clean, and the staff will be friendly and knowledgeable. Any questions I have will be addressed. The exam and report will be accurate and confidential. From patient value statement the hospital team developed a Business Case, which defines the reasons for actions and the goals they hope to achieve. Business Case Statement: Our Strategic goal is to improve the use of our resources as effectively and efficiently as possible while maintaining quality of procedure and adhering to our patient value statement Lean Journey – Process Diagnosis (Value Stream Mapping) Value Stream Mapping Session Overview • The VSM is a three day session meant to develop a comprehensive understanding of the current process and identify major areas for improvement. • The main deliverable for the VSM is an action plan, which, in addition to discovering the major areas for improvement, outlines the structure and timelines for implementing the solutions. Current State – Flow Chart In order to ensure a common understanding of the current process and to identify opportunities for improvement, the team mapped out the process from receipt of requisition to the time MRI report is sent, during the VSM. OP Flow IP Flow Inpatient Flow Outpatient Flow Total Process Steps 56 67 Total Major Wait Periods 11 13 Future State Measurement Improvements During the VSM, the hospital team identified an improved future state process that could be achieved in the next 6-12 months. The RIE has addressed the wastes captured at the VSM, moving Health Sciences North closer to their anticipated future state. Value Added Steps Non-Value Added Steps Flow Time Touch Time Current State 3 64 122 days 1h12mins Future State 3 9 91 days 1h7mins % - -86% -25% -7% Rapid Improvement Event Overview • Boundaries of a current process are defined, process steps are reaffirmed, solutions are developed and trialed, and a new standard process is in place by the end of the week. The RIE focuses on process improvements in the following areas: • Booking Process: Streamlining the process and decreasing the wait time from the point an MRI requisition is received to when an appointment is booked and the referring physician is notified of the appointment. • Patient Flow on Day of Exam: Streamlining the process on the day of exam and thereby, minimizing scanner idle time. Issue Before: 49 wastes Root Cause Lean Principle Solution After: 41 wastes addressed! Schedule Optimization Session Overview • The Schedule Optimization session is a 2 day event during which the current scheduling template is reviewed, constraints identified, and a new scheduling template is developed to reflect actual demand and maximize patient throughput. New Schedule effective March 2012. So what’s the verdict? So what’s the verdict? • Investment ~700 hours of staff time including involvement from Technologists, Management and administrative support staff • Approx. $30,000 (consultants time Ministry funded) • All aspects of this change were driven by the staff with consultants and managers acting as facilitators • Return: Scheduling template predicts access to an additional 40 patients per week (40 additional hours of scan time per week) • Ministry funds MRI time at $260.00 per hour • Potential added capacity has given the MRI over $500,000 worth of extra scan time • MRI Department has undergone a shift to sustain continuous quality improvement • Weekly mini PIP meetings to review data, ensure they stay the course and set weekly improvement goals. Nothing is too small Conclusion • Throughout MRI PIP at Health Sciences North, numerous opportunities were identified and solutions developed. Some of these solutions directly impact the process flow, while other solutions will have a more significant impact on metrics and patient satisfaction. Combined, the solutions create a future state that will optimize throughput, streamline workflow, and create an environment conducive to promoting patient-centered care and continuous improvement. The staff should be commended on their dedication to continuous improvements and open-mindedness to change. Questions or Comments?