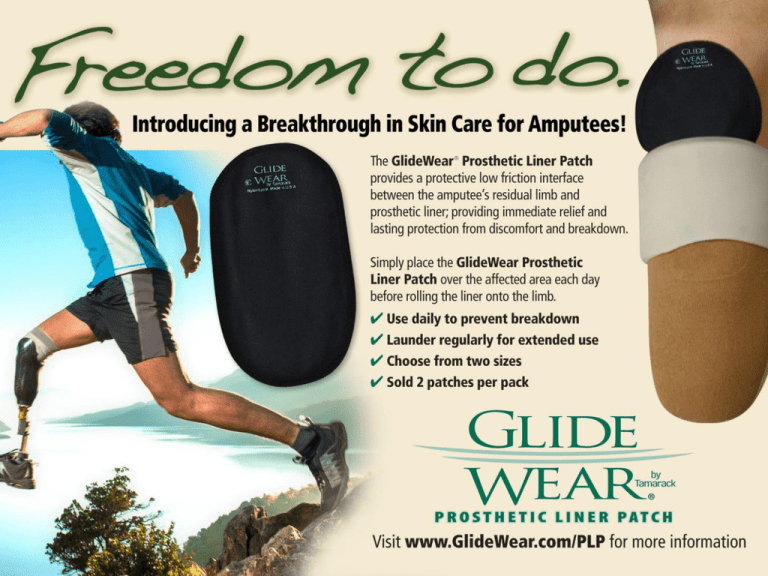

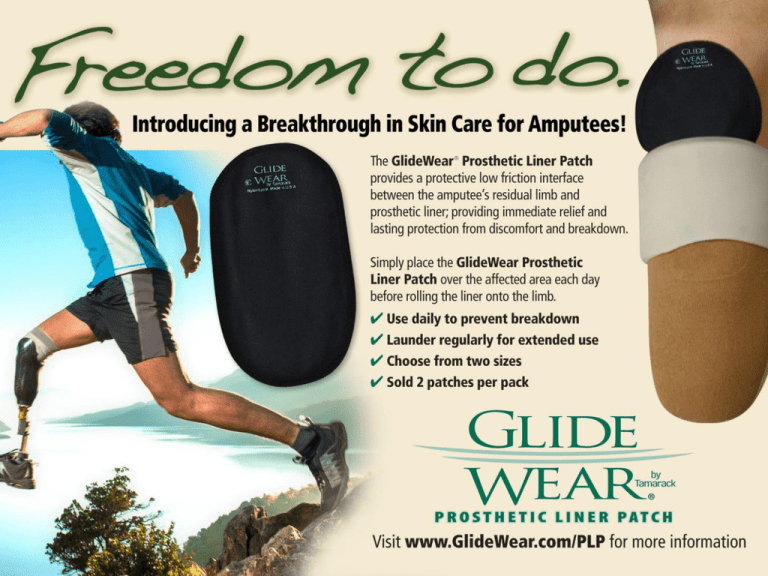

GlideWear® Prosthetic Liner Patch

Presentation of a New

Intervention for the Management

of Skin Breakdown for Amputees

Presenter Intro + Disclosures

Charles W. Kuffel MSM, CPO, FAAOP is the

President & Clinical Director at Arise Orthotics &

Prosthetics.

Kevin Hines CPO is an owner & certified

prosthetist-orthotist at Arise Orthotics &

Prosthetics.

Presenter Intro + Disclosures

Charles & Kevin both serve as clinical consultants

for Tamarack Habilitation Technologies.

Jason Pawelsky is the Sales & Marketing

Manager at Tamarack Habilitation Technologies

with 8 years of O&P product developmentrelated sales & marketing experience.

Webinar Agenda

• Discuss the skin care challenge faced by

Prosthetists and Amputees

• Introduce friction management concept and

its role in wound care

• Introduce GlideWear Prosthetic Liner Patch

• Present case studies

• Q&A

• Contact Information

The Prosthetist’s Dilemma

• Approx. 1.9 million amputees in the U.S.

• Over 65k LL amputations annually due to

diabetes alone

• Annual prosthetic liner utilization estimated

at over 200k units

• Skin integrity disruption is a constant struggle

for the Prosthetist and rising amputee

population – it is not isolated by diagnosis,

geography, liner, or device type

Interface Design Concerns

A recent survey of Prosthetists about the design of

prostheses conducted on the OandP-L (n = 95) revealed:

• Nearly 50% concluded that the most

important area for prosthetic device design

improvement is on interface materials

• The distal tibia and fibular head ranked as

most common areas of socket discomfort for

transtibial amputees.

Got Pressure?

Pressure reduction in at-risk areas is an essential

component of skin tissue health and is the

leading focus amongst clinicians.

However, pressure isn’t the only consideration…

Once a prosthetic socket is fabricated, both

friction and moisture must also be

appropriately managed.

The Impact of Friction &

Shear on Human Soft Tissue

Intrinsic

Factors

General health, nutrition, age, neuro-muscular and

neuro-sensory status, metabolic status, etc.

Global

Factors

Patient education, motivation, lifestyle, program

follow-up, etc.

Extrinsic

factors

Pressure

Friction & Shear

Microclimate

Extrinsic Factors - Summing It Up:

1.

P

FF

Fs

2.

3.

4.

By addressing the extrinsic factors, 4 results will have to be met:

1.

2.

3.

4.

Improvement of microclimate

Redistribution of pressure loads

Management of static and dynamic friction

Minimization of shear forces in at-risk areas

Repetitive Loading

• During ambulation, load is applied to the skin,

reaches a maximum and, in the unloading

phase, incurs tensile stress caused by the

weight of the prosthesis. This series of loading

cycles occurs again, and again, and again…

• Virtually all repetitive loading has a “rub”

(friction) component.

• When insufficiently addressed, skin

breakdown occurs.

Repetitive Loading

Every ambulatory person has experience with this…

– It is an occasional irritant for “Mr. Blue”

– It causes significant discomfort and occasional

breakdown for “Ms. Green”

– “Mr. Red” is unable to wear his leg until his wound

heals – keeping him from living the active lifestyle

he enjoys with his family & friends

Let’s examine what this looks

like clinically…

Tissue Trauma Examples

Conventional “Wisdom”

Red skin = “Pressure Area”

So, must reduce peak pressure… End of story.

BUT REMEMBER!

Reducing pressure decreases the clinical

control that was originally desired

Lost opportunity to enhance and extend

function

Labor intensive (costly)

How do we currently

address friction and shear?

Skin lubricants – lotions & gels

Messy to apply

Likely to spread beyond targeted area

Hydrates skin when absorbed, increasing the

coefficient of friction between skin and liner –

making skin more susceptible to trauma

Short term solution – needs frequent reapplication.

Contraindicated for some liners

How do we currently

address friction and shear?

Moisture Management Liners

Only addresses 1/3 of the equation

Not widely used amongst amputees

Skin-Drying Powders

Messy to apply

Limited duration of protection

The Friction Factor

By introducing a low friction material at the

interface of the device and skin, friction is

virtually eliminated in targeted, at-risk areas.

It’s important to mention that friction is

important when it comes to supporting proper

device fit & function– just not when it causes

shearing and skin trauma.

What is GlideWear?

Patented dual-ply low friction fabric technology

Manufactured in Minneapolis, Minnesota by

Tamarack Habilitation Technologies

First commercialized in 2009 for use in wheelchair

cushion covers and in 2013 for prosthetic liners

GlideWear is a comfortable, versatile, long-lasting and

highly effective shear management technology.

GlideWear® Prosthetic Liner Patch

Indications for Use

Indicated for nearly every amputee who experiences

discomfort and skin breakdown from their prosthetic liner

or socket.

Critical Sites of Skin Breakdown include…

Patella

Popliteal

Distal anterior tibia

Fibular head

Also recommended as a tool to prevent

premature liner breakdown!

GlideWear® Prosthetic Liner Patch

Features

Easy to Use

Available in two sizes. Place appropriately-sized GlideWear Patch

against the targeted area before rolling the liner over the top.*

Provides Targeted Shear Reduction

Shearing occurs between the dual ply GlideWear fabric; not against

the skin in at-risk areas.

Extremely Durable

Reuse daily and launder frequently for months of worry-free skin protection

Tested through 100 wash/dry cycles and 180,000 rub cycles to ensure

durability through long term use.

*Do not apply directly over open wounds.

GlideWear® Prosthetic Liner Patch

Benefits

For Amputees

For Practitioners

Immediate improvement in

comfort

Less extensive socket

recontouring = better fit and

function

Better wound-healing

environment

Eliminates need for messy and

ineffectual cream & powder use

Reduction of “early returns” due

to nagging skin problems

Reduced practitioner time on

non-billable facility expense

Protect liners from early wear-out

No reimbursement battles!

Enjoy months of daily use with a

single patch -> cost-effective!

GlideWear® Prosthetic Liner Patch

User Instructions

1) Position the GlideWear Prosthetic

Liner Patch over the affected area.

1) Roll the liner over the GlideWear

Patch to complete placement process.

1) Use clean, dry patch daily to ensure lasting

protection. Launder as needed.

GlideWear® Prosthetic Liner Patch

Purchasing Options

Choose from 2 size options:

Small (2.5 in. x 4.75 in.)

Suitable size for most users!

USD $27 MSRP

Large (4.5 in. x 7.5 in.)

For larger limbs & coverage needs

USD $34 MSRP

Sold 2 patches (same size) per pack

GlideWear Tips

GlideWear is not intended for placement directly against open

wounds.

Always follow standard wound cleaning & coverage

procedures (as recommended by a licensed healthcare

professional) to support a healthy wound-healing

environment.

To avoid recurrence of skin breakdown after healing,

amputees should continue using the GlideWear Prosthetic

Liner Patch daily to protect against future issues in at-risk

areas.

Conclusions

• Skin breakdown in the amputee population

can be addressed in numerous ways.

• Pressure, shear, and microclimate must all be

managed to optimize device fit, comfort, and

skin protection.

• GlideWear offers a simple, low-cost, and longlasting solution for shear-related discomfort

and breakdown for amputees.

Q&A + Contact Info

GlideWear Prosthetic Liner Patch

Questions/Comments?

Please contact:

To Order GlideWear Prosthetic

Liner Patches, or receive

Product Support please contact:

Jason Pawelsky

Becker Orthopedic

Sales & Marketing Manager

Customer Service

JasonP@tamarackhti.com mail@beckerorthopedic.net

(866) 795-0057 toll-free

(800) 521-2192 toll-free

(763) 795-0057 local

(800) 923-2537 fax

www.glidewear.com/PLP

BeckerOrthopedic.com

© 2014 Tamarack Habilitation Technologies, Inc. All Rights Reserved

CEU CREDITS

• To obtain CEU Credits, please refer back to the

listing for this presentation on the Becker

website and click the Test Questions link.

• After completing the Test Questions Form,

please print the document for your records.

You can then scan the document and upload it

to us by selecting the Clinical/Technical

Support button on the Becker website, or fax

it to us at (800) 923-2537.