Presentation Materials

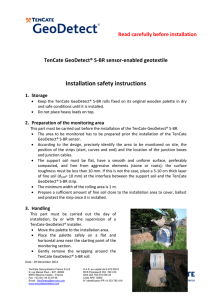

advertisement

TenCateTM Mirafi® Geosynthetics Bruce A Lacina, P.E. Roadway Reinforcement Technical Manager TenCateTM is a 300+ year old company and the global leader in geosynthetics. We develop and produce materials that increase performance, reduce costs and enable people to achieve what was once unachievable. Our goal is to contribute significantly to progress in the industries in which we work. TenCateTM Geosynthetics make the difference. Protective & Outdoor Fabrics Aerospace Composites Armor Composites 2 | TenCate Road Show Geosynthetics Industrial Fabrics Synthetic Grass Mirafi® RSi-Series Woven Geotextiles The 1st Integrated Geosynthetic for Base Reinforcement and Subgrade Stabilization 3 | TenCate Road Show Mirafi® RSi-Series Woven Geotextiles Integration (hence the “i”) of 4 Key Properties for Base Reinforcement and Subgrade Stabilization - High Modulus especially in CMD High Water Flow/Permittivity Separation (US sieve #40) High Interaction Coefficient (Confinement) Plus added benefit of Product Identification 4 | TenCate Road Show Project Case Study: Mirafi® RS580i – Ankeny Centennial High School Access Road 5 | TenCate Road Show H₂Ri 6 | TenCate Road Show Patented 4DG Yarn in H₂Ri 7 | TenCate Road Show 8 | TenCate Road Show Mirafi® H₂Ri Integration of 5 Key Properties for Base Reinforcement and Subgrade Stabilization Plus Wicking Capability - High Tensile Modulus (stiffness) especially in CMD High Water Flow/Permittivity Excellent Separation High Interaction Coefficient (Confinement) Plus added benefit of Product Identification 9 | TenCate Road Show Product Identification 10 | TenCate Road Show Questions about Mirafi® Geosynthetics? Contact your TenCateTM representative: 800-685-9990 or www.mirafi.com 11 | TenCate Road Show Kansas State University Investigation of Bearing Capacity of GeotextileReinforced Paved Roads Milad Saghebfar Bruce Lacina Mustaque Hossain 2 0 1 3 M I D - C O N TI N E N T T R AN S P O R TAT I O N R E S E AR C H S Y M P O S I UM Outline Background Test sections Instrument installation Monitoring Conclusions Rutting Under Wheel Loading Kansas State University Accelerated Pavement Testing (APT) Facility Department of Civil Engineering and the Kansas Department of Transportation (KDOT) developed the APT facility at 1997. The 18 th full-scale pavement test is now being completed Test sections Section E Section F Section G Section H Geosynthetics None RS380i RS580i RS580i Base 12” crushed stone 12” crushed stone 10” crushed stone 12” crushed stone Hot-MixAsphalt 6” SR-12.5A 6” SR-12.5A 4” SR-12.5A 6” SR-12.5A *SR-12.5A- 12.5-mm Superpave mixture with RAP Test Section Layout 10’ ↑ 10’ N Middle Pit Section E 10’ South Pit Section G Section F 16’ 10’ Section H 16’ Test Sections Section E Section F Section G Section H 152 HMA 6” mm HMA HMA 1526”mm HMA 1024”mm HMA HMA 6”mm HMA 152 HMA 12” AB3 305 mm AB-3 25410” mmAB3 AB-3 305 mm AB-3 12” AB3 12”mm AB3 305 AB-3 Pressure cells Geokon 3500 pressure cells 2 per section Geotextile Strain Gages Vishay Micro-Measurement 6 per product H-bar Strain Gages • Tokyo Sokki Kenkyujo Co. • 6 per section Construction (Subgrade CBR = 2.6; E=4,700 psi) APT Machine Loading and Monitoring 18-kip load 90 psi tire pressure Truncated normal distribution Pressure cell, theromcouple and strain readings taken periodically Transverse profile and rut depth measurments periodically APT Machine Wander 80 76 70 50 40 30 20 10 10 12 15 18 21 24 27 30 33 35 37 38 38 37 35 33 30 27 24 21 18 15 12 10 0 -150 -137.5 -125 -112.5 -100 -87.5 -75 -62.5 -50 -37.5 -25 -12.5 0 12.5 25 37.5 50 62.5 75 87.5 100 112.5 125 137.5 150 Number of Cycles 60 Horizontal Wander Position (mm) Monitoring Rut depth 18 16 Average Rut Depth (mm) 14 12 10 8 6 4 2 Section E Section F Section G Section H 0 0 100,000 200,000 300,000 Number of Passes 400,000 500,000 Pressure on Subgrade 80 Pressure (kPa) 60 40 20 Section E Section F Section G Section H 0 0 100,000 200,000 Number of Passes 300,000 400,000 Longitudinal strains bottom of HMA 900 800 Long Strain Bottom of HMA(x10-6) 700 600 500 400 300 200 100 Section E Section F Section G Section H 0 0 100000 200000 Number of Passes 300000 400000 Transverse strains bottom of HMA Trans. Strain Bottom of HMA(x10-6) 800 700 600 500 400 300 200 100 Section E Section F Section G Section H 0 0 100000 200000 Number of Passes 300000 400000 Strain in geotextiles 800 600 500 400 300 200 Section F 100 Section G Section H 0 0 100000 200000 300000 400000 600 Number of Passes Trans. Strain (x10-6) Long. Strain (x10-6) 700 500 400 300 200 Section F 100 Section G Section H 0 0 100000 200000 300000 Number of Passes 400000 Conclusions Reinforced sections (sections F and H) performed better than the control in terms of rutting and pressure on subgrade. Pressure and strains in the reinforced sections did not change much until about 100,000 wheels passes. After that, geotextiles was mobilized and these parameters changed considerably.