Berea College

advertisement

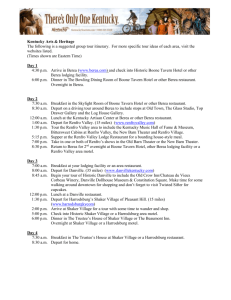

Berea College Energy, Natural Resources and Sustainability Progress Towards ACUPCC Goals Presentation for AASHE/STARS Webcast June 2012 From Humble Beginnings • Berea College was founded in 1855 as a Utopian experiment - to educate students and serve the surrounding area • First interracial and coeducational school in the South • Berea College offers a nationally acclaimed education to students which represent a wide range of backgrounds • • No tuition Labor requirement for all students • One of the college’s great commitments urges its students to live simply and with respect for the environment Berea College – Who and what is there? •140 acres •30+ buildings •15+ residence halls •Deep Green Student Residence currently under construction • 1600+ students •500+ staff members Berea’s Approach to Reducing Energy Consumption People Materials Machines Processes Where We’ve Been •People •Training of building users •New employee orientation •Machines •Central plant for both heating and cooling •Eliminate individual building chillers •Shutdown individual building boilers Where We’ve Been •Processes •Introduce building automation via various platforms •Heating and cooling set points coordinated •Real time energy monitoring •Value commission-mechanical systems •Materials •Converted from coal to natural gas and steam to hot water •Lighting retrofits •Occupancy sensors Where We’ve Been • • • • • • Geothermal systems in 5 buildings • 1997 - 2005 Sustainable renovation standards developed in 2002 Campus Environmental Policy Committee established in 2007 Energy Master Plan to guide new construction and conservation efforts (2007) Set goal of 45% reduction in energy use by 2015 Established College Energy Manager’s position in 2011 – energy and sustainable operations primary focus Where We’ve Been • Funding of Capital Projects – intentional • Savings accrue to college • Over $150 million in sustainable renovation •Draper Building Renovations (2002) •Water efficiency and stormwater management •Rainwater capture for flushing •Recycled and natural building materials •Daylight and ventilation changes allowed for reduction in energy consumption Where We’ve Been •Bruce-Trades Building (2002) •Utilize thermal mass to reduce energy needs •66 solar panels installed •15,000 watt system •A monitoring system allows real time information to be accessible to students and others •Currently collecting data on feasibility of wind resources on campus •New power plant constructed 2006 •$23 million, includes distribution •Can easily retrofit for use of biofuels Where We’ve Been •Ecovillage – 2006 •Ecologically and socially sustainable residential and learning complex •Includes Child Development Center, Commons House, Ecological Machine, SENS demonstration house (off-grid) •The sustainability goals of the Ecovillage include: • reducing energy use by 75% •reducing per capita water use by 75% •reusing or composting at least 50% of waste. Where We’ve Been •Ecovillage – 2006 (continued) •The complex includes 50 apartments (18 original and 32 new) •Key features of the Ecovillage apartments include: •solar tubes and compact fluorescent lighting •low-flow toilets and showerheads •low-VOC carpets and paints •ceiling fans •outdoor clotheslines for drying clothes Where We’ve Been Boone Tavern Renovations (2009) • First LEED Certified hotel in Kentucky • More efficient heating and cooling systems allow a drop in energy consumption of 17.6% • Included operable windows, ceiling fans in all guest rooms, master power switches, lighting retrofits, natural lighting (addition of skylights and Solartubes), HVAC upgrades • Cutting edge technology including a charging station for electric vehicles • Ongoing operations continue to be ecofriendly Berea College Direct Energy Consumption Transition from coal to natural gas primary driver: Not Just About Energy •Water •More efficient fixtures •More awareness of water use •Recycling (program began in 1991) •Berea College recycles 22% of solid waste produced •Recycling bins located around campus and in every student residence •Numerous recycling sites allow for greater numbers of items such as: •Batteries, electronics, paper, ink, aluminum, plastic, etc. •Food Waste •Dining services compost all food waste •Switch to tray-less dining cut food waste by 15% •Savings used to increase local foods purchasing Where We Are Now • “Low hanging fruit” has been harvested •Seeking out next level of strategies • Three-year energy plan to establish energy baselines by building, identify potential projects and expected savings in energy, GHG emissions and carbon footprint • Construction of Deep Green Student Residence to be LEED Platinum certified and achieve petal recognition under LBC Where We Are Now Deep Green Residence Hall General Info Area (g.s.f.) # of beds Estimated cost Cost per bed LEED LBC 42000 122 $15M $123K 2009 NC Platinum - currently pursuing ~85 points Petal Recognition Energy EUI Percent reduction PV Technologies HVAC System 40 - 50 kW (12% to 15% of load) Master switches, occupancy sensors, window-open sensors Centralized geothermal Water Technologies Percent reduction Low-flow (State rejected black and grey-water recovery and composting toilets) 40% 32 54% Notable Materials LBC Red List Wood harvested in College Forest (FSC) and on-site 100% recycled brick IEQ No Red List chemicals Site Site area Stormwater Heat Island Vegetation 3 acres Rain gardens, porous paving Cool roof, porous paving, green islands Native Student Involvement Student labor for furniture (from forest harveted wood) Building as Teaching Tool Building dashboard, residence life programming Where We Are Headed •People •Orientation presentation for 1st year students •Emphasis on energy and sustainability in residence halls •Update of Climate Action Plan and Sustainability Plan •Plans become focus of Sustainability Committee •Behavior change as focus for staff and students •Real time energy monitoring •Focus on integrating plans in curriculum •Focus on integrating with community efforts and planning •Machines •Smaller boiler used in summer •Shut down unneeded boilers •Explore uses of high efficiency condensing boilers, geothermal for certain buildings and needs Where We Are Headed •Processes • Consolidation to single, campus-wide building control system •Wireless thermostats in buildings • Utility analysis by building to identify energy hogs • Following green renovation standards • Aggressive plan for climate neutrality included in CAP update • Create metrics and tracking systems to measure and analyze performance •Materials •Eliminating fossil fuel use •Focusing on renewable energy resources •Solar •Wind •Fuel Cells Presentation Prepared By: Steve Karcher VP Operations and Sustainability Steve_Karcher@berea.edu Diane Zekind Berea College Energy Manager Diane_Zekind@berea.edu Andrew Wiley Student Assistant – Office of Operations and Sustainability andwly@gmail.com