Alain Humbeek

advertisement

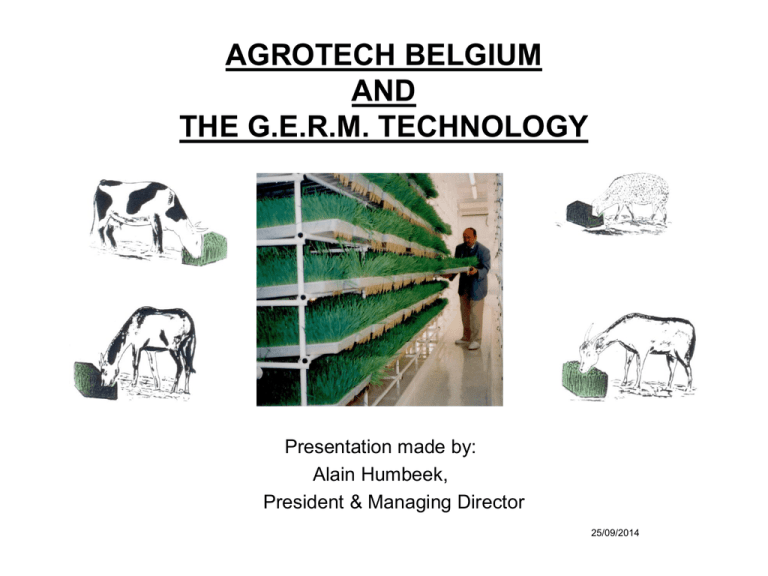

AGROTECH BELGIUM AND THE G.E.R.M. TECHNOLOGY Presentation made by: Alain Humbeek, President & Managing Director 25/09/2014 THE COMPANY: AGROTECH BELGIUM IN A NUTSHELL • • • • • • • • • • • High-tech company in agricultural and agro-industrial engineering. Incorporated in 1986… after 10 years of intensive R&D. Inventor and developer of the original G.E.R.M. technology. A giant leap in the field of applied agricultural technology Distinguished by a collection of prestigious international Awards. An impressive amount of press articles and broadcasts in the international mass-media (newspapers, magazines, TV, radio, etc.) A worldwide reputation. A typical high-tech company: « a small firm with a great product » Worldwide markets. Direct sales to end-users and investors. Strategic approach of international markets. MORE THAN 38 YEARS OF KNOW-HOW AND EXPERTISE THE G.E.R.M. TECHNOLOGY • G erminating E nergy R eleasing M ethod developed by AGROTECH BELGIUM • Result of a perfect combination, harmonization and synchronization of all parameters involved in the ideal climate in order to optimize both the quantity and the quality of the fodder produced, with the purpose of maximizing zootechnical performances. • Zootechnical performances: increase of milk production, acceleration of fattening process, better reproductive performances, better resistance to diseases, enhanced productivity of the cattle, etc. … While the role of traditional feeding that completes this fundamental GERM ration is principally to fill the stomach of the animal by giving weight and volume to the feed intake. 100% NATURAL • NO SOLUBLE NUTRIENTS, NO FERTILIZERS, NO PESTICIDES, NO HORMONES, NO ADDITIVES, NO CHEMICALS. • OPERATIONAL IN THE MIDDLE OF THE DESERT OR IN THE CORE OF SIBERIA ! FROM SEED TO GRASS IN ONLY 8 DAYS THE FRESH FODDER FACTORY • • • • • • Professional and industrial operation. Managed by a staff of specialists (zootechnician and technician) in order to: optimize zootechnical performances guarantee an efficient and professional running to both the owner and ourselves. Type of clients: industrial farm (own use), community of farms (own use), investors from public or private sector (selling fresh fodder retail to small farmers),… The growth chamber is totally insulated. The shelving is divided into 8 sections, each section being at a different stage of growth. It takes 140 Kg of cereal seeds (barley, wheat) per day to obtain 1 ton of fodder. FFF – A VERY PROFITABLE INVESTMENT • Profitability ratios are very positive: R.O.E. between 17 and 25% in average R.O.I. between 18 and 27% in average Payback Period between 3 and 5 years in average. - Worldwide average for a FFF with an output capacity of 20 T/day operated by photovoltaic energy - Hypothesis of 100% equity case without a long-term borrowing (no “gearing effect”). - The profitability increases with the output capacity, as a result of scale economies. • Important socio-economic consequences for the national livestock sector and also very interesting financial operation that generates important revenues (public investor and NNFFF project: important long-term cash-flow for the national budget). • FFF with an output capacity of 20 T/day occupies about 2,900 sq.m. and replaces the capacity of more than 200 hectares of grazing land at the production level. Land thus reclaimed can be put to other profitable uses, increasing overall profitability of the farm. • More than 98% water saving. The GERM technology uses less than 2% of the amount of water required by conventional methods for the same output. ADVANTAGES OF THE GERM TECHNOLOGY • • • • • • TECHNOLOGICAL ZOOTECHNICAL FINANCIAL COST EFFECTIVE MACRO-ECONOMIC MORE EFFICIENT MANAGEMENT See detailed list of advantages on our website. THANK YOU … AND LET US COOPERATE ! AGROTECH BELGIUM rue François Vekemans, 105 1120 – Brussels Belgium Tel.: 32/2-268.31.74 Fax: 32/2-268.31.74 info@agrotech-belgium.com www.agrotech-belgium.com