Waste to fuel solution

advertisement

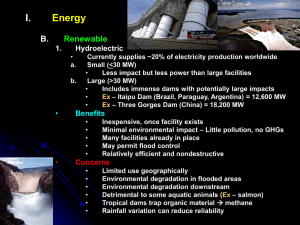

+ GERMAN TECHNOLOGY Advanced Waste to Fuel Technology Efficient waste management solutions www.greenalliance.eu Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Overview Problems Current solutions Issues Solution Benefits Technology Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Problems Massive amounts of urban and industrial waste Necessity to recycle and minimize environmental impact and hazards High cost of managing Recycling programs Inefficiency of Recycling programs Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Current solutions Incineration • Obsolete Landfill • Obsolete Recycling – Separation on source • Inefficient – High Cost Recycling – Separation at the factory • More efficient – High Cost Recycling – Automated separation at the factory • Higher Efficiency – Higher Cost Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Issues with current solutions Some methods have high environmental impact and are obsolete All solutions have high Costs both CAPEX and OPEX All methods have a significant landfill impact and cost Municipalities have great difficulties to fund sustainable waste management solutions Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Solution Waste to Fuel conversion Minimal Environmental Impact Municipal waste Collection Metal / Glass Separation Rest Minimal Operating Costs Long Term Revenues Processing Metal Glass Output Metal Glass Fuel Fertilizer/ Ash Financials PROFIT PROFIT PROFIT PROFIT Conversion 100% Recycling Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Technology Breaking down of long chain molecules into synthetic fuel Alliance Ventures Ltd. Step 1 Mixing and cracking feedstock Step2 Separating hydrocarbons from mix Step 3 Distilling Synthetic Fuel Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Process INPUT WASTE TREATMENT • MSW (municipal solid waste) • All Plastics • Animal waste • Mineral oils • Sewage Sludge • Agricultural waste • Biomass Cultivated • Separate Glass/Metal • Create Feedstock • Particle Size : 25mm • Humidity: 20% • Inorganics: 5% PRODUCTION OUTPUT • 1.2 tns mass = 500Kg Synthetic Fuel • No Chimneys • No Pollution • No Furans • No Dioxins • No Heat • SYNTHETIC FUEL • FUEL DIESEL QUALITY • Cetane number : 65 • Freezing point : -20 oC • ASH • Fertilizer • Construction Raw Material Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu INPUT Recycled Paper MSW Agricultural Waste Sewage Sludge Plastics Tyres Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu WASTE PROCESSING Shredding Alliance Ventures Ltd. Separation Advanced Renewable Projects Coneying biofuels@allianceventures.eu + www.greenalliance.eu The BML Technology Diesel Fuel Production from Biomass by Hydrogenation Diesel (παραγωγή καυσίμων από βιομάζα με υδρογόνωση ) Cellulose (κυτταρίνη) C6H10O5 = 2,5 CO2 + (CH2)n (3,5) + H (3) C (Lignite) + C6H10O5(Cellulose) = (CH2)n + m CO2 . 33 Hydrocarbons on the brown coal + 52.8 Carbon from lignite + 13.9 CO2 formed from oxygen + 358 Cellulose = 202,6 Hydrocarbons (Diesel) + 255,4 CO2 . 33 Hydrocarbons on lignite + 52,8 Carbon from lignite + 13,9 CO2 including oxygen O + 358 Cellulose = 202,6 hydrocarbons (Diesel) + 255,4 CO2 + THE BML TECHNOLOGY The BML--‐Technology is the one and only technology, which can convert all organic input material (plastic, straw, paper, wood, olive residues, MSW etc.) In a sustainable ecological and economical way. Because we have temperatures of under 280°C centigrade, we don´t produce any of the Most toxic products like dioxins and furans. The main product we can produce with the BML--‐Plants is high quality Diesel fuel, which conforms to the European Diesel Norm EN 590 and can be used directly in all diesel engines. Also when we use biomass as input material we get synthetic diesel fuel, which conforms to EN 590 (no biodiesel!) Byproducts are distilled water, Co2, salt (mineral salt when you use biological residues) and ash (from the inorganic of the input material). + www.greenalliance.eu The process The process consists of the following steps: 1.Mixing, crushing, dehydrating (squeezing) the biomass 2.High-pressure compression and grinding of the biomass in an oxygen-free atmosphere 3.Mixing with a cheap and reusable catalyst, mainly a special prepared aluminumoxide, Al2O3 4.Introduction of the material in the kiln by an off-center screw. 5.Chemical-catalytical conversion (depolymerisation) in the kiln at temperatures of about 320 to 380 °C in an oxygen-free atmosphere to Diesel oil 6.Distillation of the produced oils in a distillation column and separation from water, char and some dust of the catalyst powder. 7.Use of produced gas and up to 10 % of oil in a CHP-facility for the production of heat and electricity for the supply of the whole plant 8.Storage of the oil in a tank for sale 9.Option: cogeneration of electricity and heat. + Plant in Spain This commercial plant was built in 2013/14 in Albacete, Spain. • Input material: Old tires, approx. 800 kg/h • Capacity: approx. 20 tons per day (about 7000 tons/a • Output: 50-55 % Diesel, 20 to 22 % Gas (used for CHP), 3-8 % Char, 6-10 % steel wire braiding from tires, 8-10 % aromatics • Efficiency: > 80 % • CHP: 450 kW • Licenses cost • Buildings for storage material etc, • Installation cost • Travel expenses for 3 supervising engineers and technicians • Hotel and lounge expenses • Supervising cost + Spain BML process – 2x6500 t/y Synthetic diesel production based on plastic & used car tires. + www.greenalliance.eu BML Synthetic Diesel production from MSW Case: MSW recycling Tarragona center Alliance Ventures Ltd. Case: KDV 2000 Tarragona center Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu OUTPUT Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Synopsis Waste to Fuel conversion Zero Environmental Impact 100% Recycling Revenue Generating Positive Income for Municipalities and Operators Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + www.greenalliance.eu Alliance Ventures Ltd. Turnkey solution Financing Engineering Operation Procurement Development Alliance Ventures Ltd. Advanced Renewable Projects biofuels@allianceventures.eu + Thank you for your attention Thomas Ferfyris Dipl.Ing www.greenalliance.eu