Presentation of NANOfutures Innovation Roadmap for 2020

advertisement

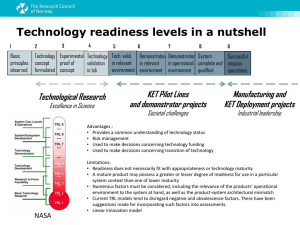

NANOfutures association Development of micro and nano technologies roadmap for 2020 Lambertini Vito Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 Roadmapping Approach NANOfutures - Grand Challenges If effective alignment of private and public efforts over promising areas is guaranteed from short to long term, European Nanotechnology is expected to give an outstanding contribution to major Societal challenges of our time: Health, demographic change and wellbeing; Food security, sustainable agriculture, marine and maritime research and the bio-economy; Secure, clean and efficient energy; Smart, green and integrated transport; Climate action, resource efficiency and raw materials; Inclusive, innovative and secure societies. Aarhus 19-21 June 2012 Roadmapping Approach NANOfutures – Industrial sectors 10 Horizontal working groups RESEARCH and TECHNOLOGY INDUSTRIALIZATION 11 ETPs COMMUNICATION SAFETY RESEARCH INDUSTRIAL SAFETY STANDARDIZATION REGULATION Tech.Transfer and Innovation Financing NETWORKING SKILLS AND EDUCATION Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 Roadmap Overview Value Chains Functional Fluids Lightweight multifunctional materials and sustainable composites Alloys Ceramics, Intermetallics Structured Surfaces Nano-enabled surfaces Nano-enabled surfaces for multi-sectorial applications Cross Sectorial Non-Technological Actions Nano structures and composites Integration of nano Infrastructure for Multiscale Modelling and Testing Nano-Micro scale manufacturing Design, Modelling and Testing of materials Key Nodes Safety & Sustainability Aarhus 19-21 June 2012 Roadmap Overview TRL 1-4 TRL 5-6 TRL 7-8 TOOLS MATERIALS MODELLING MARKET DEFINITION METROLOGY COMPONENTS ASSEMBLY FINAL PRODUCT WASTE TREATMENT ACTION ACTION ACTION NON-TECH ACTIONS NON-TECH ACTIONS to complete the definition of the market NON-TECH ACTIONS NON-TECH ACTIONS LEGENDA: SHORT TERM MEDIUM TERM LONG TERM Aarhus 19-21 June 2012 NON- TECHNOLOGICAL CROSS- CUTTING ACTIONS FOR ALL VALUE CHAINS TARGETS • Smart Sustainable Growth • effective technology transfer and innovation financing actions, boosting private investment and industrial uptake • must address the Grand Challenges of our time • Ensure high levels of safety • Research into effects on human health and environment, life-cycle assessment, test methods /equipment • Further review & effective implementation of standardization and regulation • Consolidate Public Trust • Dialogue and Education • Effective Communication STANDARDIZATION COMMUNICATION & NETWORKING ENVIRONMENT SAFETY REGULATION TECH TRANSFER & INNOVATION FINANCING EDUCATION Aarhus 19-21 June 2012 NON- TECHNOLOGICAL CROSS- CUTTING ACTIONS: DETAILS/1 TOOLS SAFETY MATERIALS MODELLING Understand the hazardous nature of the material Assess and control potential releases to workplace air during manufacturing and life cycle ENVIRONMENT Adopt safety by design into material selection Characterise and control potential release to the environment (air/soil/water) from the developed processes STANDARDIZATION REGULATION METROLOGY Appropriate nomenclature for nano COMPONENTS ASSEMBLY Assess and control potential release to workplace air during component manufacturing and assembly Apply technologies/techniques that maximise the extent to which the material is incorporated into the product in order to i) maximise functionality and ii) minimise releases to the environment FINAL PRODUCT Control potential release during professional and/or consumer use. Recommend safety advice to professional and/or consumer users Characterise and control potential release to the environment (mainly water) from the developed processes WASTE TREATMENT Control potential worker exposure during recycling & disposal Understand fate and behaviour of these materials in the environment Apply standards /SOPs for safe disposal of these materials Apply standards/SOPs for safe handling of these materials , considering the whole life cycle Appropriate level of Apply Appropriate level of regulation to standards/SOPs regulation to address address EHS issues for safe handling EHS issues whilst whilst supporting of these supporting innovation innovation materials Aarhus 19-21 June 2012 NON- TECHNOLOGICAL CROSS- CUTTING ACTIONS: DETAILS/2 TOOLS MATERIALS COMMUNICATION & NETWORKING MODELLING METROLOGY COMPONENTS FINAL PRODUCT ASSEMBLY Communication of knowledge regarding hazardous nature of the material down the supply chain. More information flow and dialogue between industry and educational experts Initiate dialogue with the public (with industry, regulators etc. ) about future potential benefits about nanotechnology. Develop tools to assess societal impacts of nanoproducts . Communication and clustering actions across different sectors and between Academia and Industry, Infrastructure facilities and Society. Better Regional/National Funding Agencies Coordination WASTE TREATMENT Effective communication to the EU society on the social and economic impact. To foster more dialogue among policy makers about best practices in nano Extra EU trans-national cooperation & Networking Involvement of investors and Investment readiness programmes for SMEs Actions for the benefit of SMEs TECH TRANSFER & INNOVATION FINANCING New business strategies and business models for nano-enabled products Support infrastructure for TT service (eco-system of labs and skilled persons) Cross-sectorial TT programme TT from academia to industry. ICT and TT commercialization tools Aarhus 19-21 June 2012 Roadmap Overview VC1 - Lightweight multifunctional materials and sustainable composites Textile and sport sector VC3 Structured Surfaces Transportation Packaging Energy Construction and buildings ICT Construction and buildings ICT (Nanoelectronics, photonics, sensors) Transportation Textile and passive funct. Energy (PV batteries, harvesting) VC5 Functional Fluids Construction and building Consumer Products (Cosmetics & Household Cleaning) ICT (Thermal & Electrical Management) Medicine (Bio-sensors, Lab on a Chip, regen. medicine) Plasma and Vacuum Engineered Surfaces VC2 - Nanoenabled surfaces for multi-sectorial applications VC4 Alloys Ceramics, Intermetallics Energy Harvesting & Conversion ICT Functional Packaging Wet Engineered Surfaces VC7 Infrastructure for Multiscale Modelling and Testing Complex Adaptive Systems for complete product design VC6 Integration of nano Direct manufacturing Transportation Medicine &Pharma Finished net shaped 3D structures for nanoelectronics & photonics Catalysis and filtration Cross Sectorial Non-Technological Actions Semi finished Aarhus 19-21 June 2012 VC1c - LIGHTWEIGHT MULTIFUNCTIONAL MATERIALS and SUSTAINABLE COMPOSITES for TRANSPORTATION TRL 1-4 TRL 5-6 TRL 7-8 TOOLS MATERIALS Development of cost effective industrial scale technologies for synthesis and technologies for dispersion/exfoliati on (extrusion) METROLOGY Thin glass/ Plastic Composites glazing with added functionality Development of methods for functionalization during synthesis to reduce production steps and alignment of nanoobjects NON-TECH ACTIONS specific to the value chain MODELLING Design of multifunctional materials tailored for different needs Understanding of relationships morphology/func tionality/triggers of multifunctional polymers COMPONENTS ASSEMBLY FINAL PRODUCT Integration of novel Low cost and materials into existing large scale production and assembly functionalized lines composites Multilayer Metal foams based materials panels Thin glass Ceramic parts Metal-foam Multilayer sandwich panel materials structures Thin glass Ceramic parts Advanced smart Monitoring of multifunctional materials foams structure, properties and Adaptation/modification functionalities of novel technologies for production on industrial Characterization scale smart polymer; and monitoring implementation of these of materials materials into different structure, devices properties and functionalities SAFETY Assess and control potential human exposure during assembly and finishing of products WASTE TREATMENT LCA and ELV LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY Characterise and control potential release of nanoparticles during waste treatment and reprocessing. Understand potential environmental hazards resulting from recycling processes Aarhus 19-21 June 2012 VC1f - LIGHTWEIGHT MULTIFUNCTIONAL MATERIALS and SUSTAINABLE COMPOSITES for CONSTRUCTION & BUILDING TRL 1-4 TRL 5-6 TRL 7-8 TOOLS MATERIALS Composites: development of materials and construction parts Multilayer barrier materials MODELLING METROLOGY COMPONENTS Integration of novel materials into existing production and assembly lines Multilayer components Monitoring of materials Composites structure, with added properties and functionality Designing of functionalities multifunctio Development of nal materials methods for Characterizatio tailored for functionalization n and different during synthesis to monitoring of needs reduce production Materials mateials steps and modelling, structure, alignment of nano- thermal properties and objects simulation and functionalities process design NON-TECH ACTIONS specific to the value chain FINAL PRODUCT ASSEMBLY LCA of the process and integration of wastes in the LCA analysis Low cost and large scale functionalize d composites Advanced smart multifunctional foams and multilayer components Adaptation of machines and process’ parameters to maintain functionalities Adaptation/modification of novel technologies for production on industrial scale smart polymer and concrete SAFETY Assess and control potential human exposure during assembly and finishing of products WASTE TREATMENT LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY Characterise and control potential release of nanoparticles during waste treatment and reprocessing. Understand potential environmental hazards resulting from recycling processes Aarhus 19-21 June 2012 ROADMAPS for ALL VALUE CHAINS and RELATED MARKETS Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 PRODUCTS AND APPLICATIONS FOR TRANSPORTATION Products Long time, low cost fuel cell membranes and batteries; Low friction engines & lubricants; Smart glass surfaces; Lightweight metal or plastic sheet for chassis; efficient tires, wiper blades, seals; sustainable lightings and heating systems; smart sensors and radar systems TRL 1-4 Thin glass Development of methods for functionalization during synthesis to reduce production steps and alignment of nanoobjects NON-TECH ACTIONS specific to the value chain Design of multifunctional materials tailored for different needs Understanding of relationships morphology/fun ctionality/trigge rs of multifunctional polymers ASSEMBLY FINAL PRODUCT SAFETY Assess and control potential human exposure during assembly and finishing of products WASTE TREATMENT TOOLS LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY Characterise and control potential release of nanoparticles during waste treatment and reprocessing. Understand potential environmental hazards resulting from recycling processes MATERIALS Liquid-based deposition processes of nano-enabled thin films on rigid organic and metallic substrates Process upscaling for deposition on rigid organic and metallic sheet materials Process development for deposition on semiflexible and flexible substrate materials NON-TECH ACTIONS specific to the value chain MODELLING METROLOGY Design and modeling strategies for improved interface adhesion with substrate and within nano-enabled layers Unraveling relationships processing / morphology / functionality of nanoenabled thin films with complex architectures SAFETY Assess and control potential human exposure during manufacture COMPONENTS FINAL PRODUCT ASSEMBLY WASTE TREATMENT Integration of novel nanoenabled surfaces on common rigid engineering materials into existing industrial production and assembly lines High speed characterization of nano-enabled thin films on rigid substrates and combinatorial approaches Implementation of novel technologies for production of nanoenabled surfaces with dedicated functionalities on flexible substrates into novel devices TOOLS MODELLING METROLOGY LEGENDA: SHORT TERM MEDIUM TERM SAFETY Characterise and control potential release of nanoparticles during waste treatment and reprocessing COMPONENTS ASSEMBLY FINAL PRODUCT WASTE TREATMENT Integration of novel materials in existing production and assembly lines (blending, inkjet, R2R) Cost effective industrial scale technologies for filler synthesis and technologies for dispersion Development of technology able to produce in reproducible way complex nanomaterials LONG TERM SAFETY Assess and control potential human exposure during assembly and finishing of products MATERIALS TRL 7-8 COMPONENTS Integration of novel Low cost and materials into existing large scale production and assembly functionalized lines composites Multilayer Metal foams based materials panels Thin glass Ceramic parts Metal-foam Multilayer sandwich panel materials structures Thin glass Ceramic parts Advanced smart Monitoring of multifunctional materials foams structure, properties and Adaptation/modification functionalities of novel technologies for production on industrial Characterization scale smart polymer; and monitoring implementation of these of materials materials into different structure, devices properties and functionalities TRL 5-6 Composites with added functionality METROLOGY TRL 7-8 Development of cost effective industrial scale technologies for synthesis and technologies for dispersion/exfoliati on (extrusion) MODELLING TRL 5-6 TRL 7-8 TRL 5-6 MATERIALS TRL 1-4 VC1,VC2,VC3,VC4, VC5,VC6,VC7 TOOLS Related actions Enabling technologies: nanocomposites, nano-enabled thin glasses, metal-foams sandwitch panels, ceramic structures, nanoporous structures, coatings, structured surfaces and functional fluids tuned for transportation TRL 1-4 Involved Value Chains NON-TECH ACTIONS specific to the value chain Modeling of nanoparticles behavior in active systems through reengineering of actual systems Design of multifunctional materials tailored for different needs SAFETY Assess and control potential human exposure during manufacture Monitori ng of material behavior in useand Analysis process control of dispersion of nanofillers into liquid Monitoring of materials structure, properties and functionalities Adaptation of existing tools for direct use or integration in devices of novel multi-fluids Adaptation of devices integration smart fluids LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY For fuel-based products, characterise and control potential release to the environment from use. Characterise and control potential release of nanoparticles during disposal and waste treatment Addressing Grand Challenges: Smart, green and integrated transport; Climate action, resource efficiency and raw materials. ETPs Aarhus 19-21 June 2012 PRODUCTS AND APPLICATIONS FOR ENERGY Products Advanced Solar cells (Including organic & hybrid PV) solid state lighting (LED, OLED, PLED) Efficient catalysis & carbon capture and storage -CCS (pollution control in fuels, in geothermal etc.) Storage technologies (hybrid batteries, gas, hydrogen). Power electronics for industrial applications and engine management) Target Market Size : - In 2030, at least 30% shares of renewables in gross final energy consumption* -In 2035 renewables, including hydro, produce roughly 15000 terawatthours (TWh) in the world** Involved Value Chains: VC1, VC2, VC3, VC4, VC6 and VC7 Multifunctional and smart polymer nanocomposites, multilayer structures, porous structures, metal alloy, ceramics, intermetallics, nanostructured surfaces, coatings and paints for energy generation, harversting, storage and distribution/management needs (high barrier properties for energy cell, enhanced gas absorption and trapping, efficient energy transmission, magnetic storage, catalytic structures and coatings, power electronics) . Addressing Grand Challenges: ETPs Secure, clean and efficient energy; Smart, green and integrated transport; Climate action, resource efficiency and raw materials; *Source: http://ec.europa.eu/energy/energy2020/roadmap/doc/com_2011_8852_en.pdf **Source: http://www.iea.org/IEAEnergy/Issue2_Renewables.pdf Aarhus 19-21 June 2012 Applications & Products ENERGY TRANSPORTATION CONSTRUCTION & BUILDINGS MEDICINE & PHARMA ICT TEXTILE AND SPORT SECTORS PACKAGING CONSUMER GOODS Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 FROM SOCIETAL CHALLNGES to PRODUCTS Medicine &Pharma maritime research; Clean and efficient energy; Green transport; Climate action, resource efficiency and raw materials; Construction and buildings Transportation Energy Packaging Inclusive, innovative and secure societies. Direct manufacturing Consumer Products (Cosmetics & Household Cleaning) VC2 Nano-enabled surfaces for multisectorial applications VC3 Structured Surfaces VC4 - Alloys Ceramics, Intermetallics Development of cost effective industrial scale technologies for synthesis and technologies for dispersion/exfoliati on (extrusion) METROLOGY Composites with added functionality Thin glass Development of methods for functionalization during synthesis to reduce production steps and alignment of nanoobjects NON-TECH ACTIONS specific to the value chain MODELLING Design of multifunctional materials tailored for different needs Understanding of relationships morphology/fun ctionality/trigge rs of multifunctional polymers TOOLS MATERIALS Composites NON-TECH ACTIONS specific to the value chain COMPONENTS ASSEMBLY FINAL PRODUCT Integration of novel Low cost and materials into existing large scale production and assembly functionalized lines composites Multilayer Metal foams based materials panels Thin glass Ceramic parts Metal-foam Multilayer sandwich panel materials structures Thin glass Ceramic parts Advanced smart Monitoring of multifunctional materials foams structure, properties and Adaptation/modification functionalities of novel technologies for production on industrial Characterization scale smart polymer; and monitoring implementation of these of materials materials into different structure, devices properties and functionalities TRL 7-8 agriculture, marine and MATERIALS TRL 5-6 Food security, sustainable ICT TOOLS TRL 1-4 and wellbeing; VC1 Lightweight multifunctional mat. and sustainable composites TRL 7-8 Textile and sport sector TRL 5-6 Health, demographic change Technologiocal and non-techn actions Cross KET Value chains TRL 1-4 Societal Challenges Applications & Products Multilayer materials WASTE TREATMENT LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY Assess and control potential human exposure during SAFETY assembly and finishing of Characterise and control METROLOGY COMPONENTS ASSEMBLY MODELLING products potential release of nanoparticles during waste treatment and reprocessing. Understand potential Integrated environmental hazards resulting frommultilayer recycling Design materials processes methodologies Assembled for foams multilayer materials production Control of nanolayer interfaces and adhesion Design methodologies Control of for foams production nanolayer and joining interfaces and technologies adhesion Materials Nano control of modelling, porous thermal structuring simulation and process design SAFETY Assess and control potential human exposure during manufacture FINAL PRODUCT WASTE TREATMENT LEGENDA: SHORT TERM MEDIUM TERM LONG TERM SAFETY Characterise and control potential release of nanoparticles during waste treatment and reprocessing VC5 Functional Fluids VC6 Integration of nano VC7 Infrastructure for Multiscale Modelling and Testing Aarhus 19-21 June 2012 FROM SOCIETAL CHALLNGES to PRODUCTS Societal Challenges Smart, green and integrated transport; Climate action, resource efficiency and raw materials. Applications & Products Transport Cross KET Value chains Technologiocal and non-techn actions Cost effective industrial scale synthesis and dispersion of nano-objects VC1 Lightweight materials and sustainable composites for TRANSPORTATION Building & Construction Metal-foam sandwich panel structures Integration of novel materials into existing production and assembly lines VC2, VC3, VC4, VC5, VC6, VC7 for TRANSPORTATION Energy VC1, VC2, VC3, VC5, VC6, VC7 for CONSTRUCTION Multilayer materials Thin glass Packaging VC1, VC2, VC3, VC4, VC6, VC7 for ENERGY … Characterization and monitoring of materials structure, properties and functionalities Functionalization methods during synthesis to reduce production steps Smart polymer on industrial scale; implementation of these materials into different devices Understanding of relationships morphology/functionality/triggers of multifunctional polymers SAFETY Common NON-TECH ACTIONS to all value chain Monitoring of materials structure, properties and functionalities Design of multifunctional materials tailored for different needs Green and large scale functionalized composites Human exposure Characterise and control potential release of nanoparticles during waste treatment and reprocessing. Aarhus 19-21 June 2012 NANOfutures European Technology Innovation Platform Roadmapping Approach Roadmap Overview Roadmap for Applications & Products Roadmap for grand challenges Conclusion Aarhus 19-21 June 2012 Conclusion • The NANOfutures Integrated Research and Innovation Roadmap has been drafted, focusing on market-driven value chains and including also broad cross-cutting actions. • The Roadmap has been circulated for further development (definition of expected budget, finalization of non-tech actions specific to the value chains) among ETPs, Working Groups and Key Node experts. • The Final Roadmap will be released at the end of July, but it will be a living document!! Aarhus 19-21 June 2012