Dartington primary school case study

advertisement

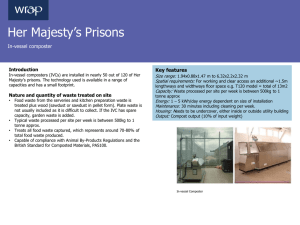

Dartington Primary School Ridan Introduction Dartington C of E Primary School in Devon has approximately 340 pupils from ages 3-11. A grant provided by Devon County Council’s ‘Cutting your Wasteline’ programme provided an ideal opportunity to buy essential equipment to purchase the Ridan, part match funded by the Parents Teachers Friends Association (£380). This was in-line with their status as an eco-school and complemented their move to a new ‘eco-build’ site in February 2010. After considering many different types of composter two different models were capable of treating the average 18 kgs of food waste produced daily by the school. One was prohibitively expensive and so the Ridan was selected as the best technology to meet the school’s requirements. Nature and quantity of waste treated on site • • • Food waste arises from the preparation of school meals and leftovers from school dinners and packed lunches The outdoor areas of the school site are managed by grounds maintenance contractors who remove the organic garden waste but leave some of this waste for use in the composter when requested The food waste is mixed with an equal amount garden waste (approximately 17-19 kg per day ) and 50 litres of dry wood chip that acts as a bulking agent Key features Name: RIDAN composter medium Size: 2.4x1.1x1.6 m Spatial requirements: as above Capacity: Composting 17-19kgs food waste daily Energy: None Housing: None Maintenance: No maintenance required Output: Compost for onsite use “Composting has become a permanent part of school life” Karen Bradford, Dartington CE Primary School RIDAN with school children Dartington School Lessons Learnt Positive impact on catering team towards recycling following the introduction of the Ridan, whereas previously they stated that they “didn’t have the time to recycle” Original wood chip was too wet, therefore changed to a different type How food is separated for treatment • The whole school community is involved in collecting waste for the composter • First the children, with the support of Mealtime Assistants, sort their waste into the appropriate containers at break times and lunchtimes • Secondly, the school’s catering team sorts the waste created from the preparation of meals for Dartington Primary and Broadhempston Primary Schools • Teaching assistants for both Key Stage One and Two help to clean waste bins and take the full bins to the Ridan composter. How the on-site treatment system is managed • The day to day running requires loading the composter and washing out the food waste caddies and takes approximately 20 minutes • A member of the grounds maintenance contractor team loads the food waste, garden waste and wood chip into the unit, making sure the ‘mix’ is right for quality compost output. Composting has been written in to this individual’s job description to ensure these responsibilities are carried out • The school has used the Ridan since 2009 and it is still going strong. The jacket and insulation has suffered some damage from rats • No specific skills are required, other than a basic understanding of the ingredients and composting process which can be gained from the web or expert advice given freely by the Devon Community Composting Network. Use of outputs from treatment The nutrient rich compost is used on-site around the garden Year 5 pupils harvested vegetables from their class garden to make soup Costs • Capital and start up costs £1,610; (this was an introductory offer – actual cost is £2250 + vat) funded by Devon County Council’s ‘Cutting your Wasteline’ programme, the Devon Community Composting Network and the Parents, Teachers and Friends Association (PTFA) • In 2012 the school used a 'Cutting your Wasteline' grant from Devon County Council to purchase a Scotty's Hot Box for the maturation of the compost. They had previously managed without but have found this speeds up the process of maturation • There are no running costs since the time incurred to manage the composter is absorbed into the grounds maintenance activities • Wood chip is sourced free of charge from a local tree surgeon • No routine maintenance costs • Waste management savings • Savings are negligible (maybe £200 per year) and would be offset by the labour cost; financial gains are not a motivating factor in composting for Dartington. This case study is part of a series of case studies focussing on the on-site treatment of organic waste. Other case studies in this series are: Eriska Hotel; Housing 21; Millets Farm Centre; University of Southampton; University of Bradford; and Her Majesty’s Prison Service www.wrap.org.uk/on_site_treatment While steps have been taken to ensure its accuracy, WRAP cannot accept responsibility or be held liable to any person for any loss or damage arising out of or in connection with this information being inaccurate, incomplete or misleading. This material is copyrighted. It may be reproduced free of charge subject to the material being accurate and not used in a misleading context. The source of the material must be identified and the copyright status acknowledged. This material must not be used to endorse or used to suggest WRAP’s endorsement of a commercial product or service. For more detail, please refer to our Terms & Conditions on our website - www.wrap.org.uk Waste & Resources The Old Academy Action Programme 21 Horse Fair Banbury, Oxon OX16 OAH Tel: 01295 819 900 Fax: 01295 819 911 E-mail info@wrap.org.uk Helpline freephone 0808 100 2040 www.wrap.org.uk