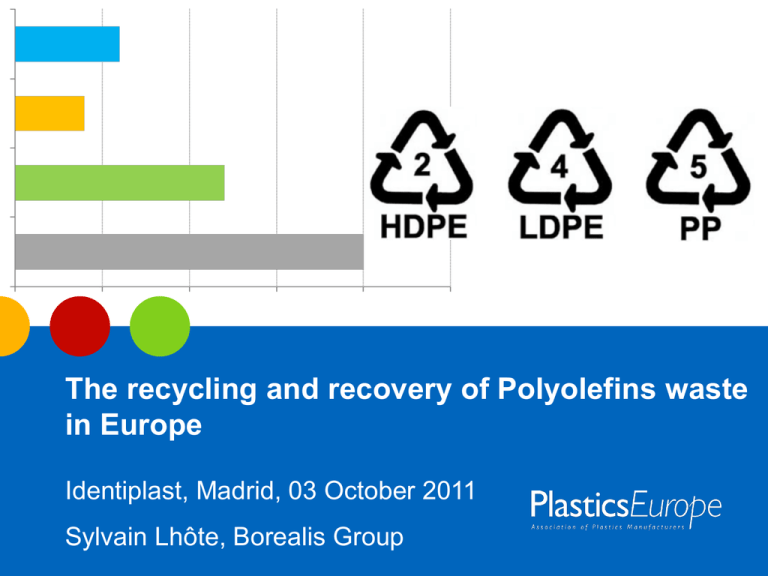

The recycling and recovery of Polyolefins waste in

advertisement

The recycling and recovery of Polyolefins waste in Europe Identiplast, Madrid, 03 October 2011 Sylvain Lhôte, Borealis Group European Polyolefins Industry • European plastics / polyolefins demand and market segments (2009) 45 MT European Plastics Demand by Resin and Market Segments – 2009 (PlasticsEurope PEMRG) 2 The challenges • • • • Polyolefins are recyclable materials Some iconic recovery or recycling practices Large volumes available for collection Strong demand for quality recyclates... ____________ • Many applications are still seen as nonrecyclable... • ...or are barred from “quotas driven” recycling schemes • Industry has limited data-based analysis of recycling and recovery in Europe 3 The questions • What are the recycling and recovery rates of rigid PO applications at end of life? • What factors drive different recovery performances of rigid PO waste? • How does PO recovery performance fit in a “zero landfill waste” management vision? 4 The study • A first comprehensive assessment of rigid PO recovery and recycling in Europe commissioned by PlasticsEurope PO Group to Consultic • 5 countries analysed in detail for year 2009 EU 27+2 extrapolation France Germany Poland Spain UK Austria, Belgium, Cyprus, Czech R., Denmark, Estonia, Finland, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Slovenia, Sweden, Switzerland • Focus on rigid PE (all types) and PP in 4 market segments: • • • • Bottles, Other Rigid Packaging, Automotive (ELV), Appliances (WEEE) 5 The big picture 4.7 MT of rigid PO waste, 57% recovery rigid PP waste 6 The national pictures Is zero landfill within reach? Treatment of rigid PO Waste - 2009 by countries France 139 Germany 191 270 231 Poland 17 Spain 475 63 52 204 39 259 50 UK seconds with ~29%, due to the high volumes of HDPEbottle collection and recycling. Poland has the lowest recycling ratio of <10%, as the recycling of plastic packaging is mainly based on PET bottles and PE film. 175 132 UK Germany is the country with the highest recycling ratio of rigid PE and PP waste: ~32%. 448 Recycling EU 27 +2 1.092 1.600 1.974 Energy Recovery Disposal 0% 7 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% PE waste treatment Recycling and recovery on par Treatment of rigid PE Waste - 2009 by countries France 115 Germany 71 117 100 Poland 11 Spain UK has the highest recycling ratio: ~48% due to high collection of HDPE milkbottles from the households. 236 32 30 France seconds the UK with a ratio of ~38%. Again Poland has the lowest recycling ratio of rigid PE of <10%. 86 78 UK 19 145 181 26 160 Recycling EU 27 +2 755 780 864 Energy Recovery Disposal 0% 8 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% PP waste treatment Effective collection unlocks recovery potential Treatment of rigid PP Waste 2009 by countries France 24 120 Germany 153 131 Poland 6 Spain 31 22 UK 240 Automotive (battery cases and bumpers) plays a relevant role in rigid PPrecycling in Germany. 89 54 24 20 All the other countries are below 13 %. 115 24 Germany shows highest recycling ratio of rigid PP: ~33%, a result of the dry bin collection system for packaging waste 288 Recycling EU 27 +2 337 820 1.110 Energy Recovery Disposal 0% 9 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% What drives high recovery rates? Treatment of rigid PP-bottle waste... France 10 Germany 4 2 4 Spain 4 UK EU 27 +2 24 1 Germany 8 Poland 3 3 France 4 8 20 Poland ... and other rigid PP-packaging waste 8 3 67 UK 65 177 3 26 9 6 3 49 48 74 18 217 Recycling EU 27 +2 Energy 166 Recovery 55 74 75 Spain 10 112 R 672 691 E Disposal 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 0% 10% D 20% 30% 40% Recycling 50% 60% 70% Recovery 80% 90% 100% Landfll 10 What drives high recovery rates? • Some PO fractions are already rather well recycled • • • • Up to >70% for PE bottles in UK, >50% of DE automotive PP waste With good quality products (e.g. food contact approved HDPE) Packaging non-bottles (PE & PP) is rather low: 11 – 13% only WEEE is very low, except in the UK • Recovery and recycling rates are heavily conditioned by: • • • • The development of more effective collection schemes (FR pilot) Landfill ban or restriction (DE) Energy recovery capacities National / markets specificities • Milk bottles in the UK • Automotive in DE, ES 11 Our conclusions (1/2) • 55-60% of rigid PO waste were recovered in 2009 making a key contribution to plastics recycling and recovery in Europe. • >1 MT of rigid PO was recycled in Europe in 2009 with clear potential to increase recycling exist in many countries • As seen in DE, CH, SW, or AT, a “zero landfill” aspiration is possible with combination of recycling and energy recovery • Demand for quality recycled PP & PE can support a step change in sorting techniques and investments – retailers can exert a strong pull 12 Our conclusions (2/2) • A supportive regulatory frame is necessary to maximise PO waste recovery in Europe. • Such framework should focus on • • • • Restricting (cheap) landfilling Extending collection to non-bottles rigid packaging Enhancing and simplifying collection (all “dry” waste in one bin?) Improving rapid identification techniques and sorting schemes (from mixed waste) • Addressing with EFSA requirements for streamlined food-contact approval for recycled polymers 13