PROCESSING OF

PET BOTTLES

MOHAMMED ALZAYER

CHRIS CLAY

XINHANG SHEN

Mat E 453

December 11th, 2014

Outline

• Background

Amcor

Blow Molding

Recycling

• Fluid Mechanics

Temperature

Molecular Weight

• Bottle Processing

Purification

Preforms

Bottles

• Conclusions

Background: AMCOR

• Global Company

– Australian

• 1860 as Australian Paper

Manufacturers

• 1986 changed name

– 90% Food industry

– 43 countries

• West EU and NA

– 180 plants

– 27,000 employees

• Ames

–

–

–

–

1997

175 Employees

10% of Ames Power

Primarily Preform

Background: Blow Molding

• Blow Molding:

Using gas pressure to expand a

polymer to a desired shape.

• History [1]:

Developed: 1800s (baby rattles!)

1st PET bottle: December, 1942

• Today [1]:

30-40 billion plastic bottles/year

(US alone)

Figure 1: Blue baby rattle [2]

Background: Blow Molding

• General Process [1]:

1.

2.

3.

4.

5.

6.

7.

Melt thermoplastic resin

Extrude through die head

Form hollow Parison

Drop Parison through mold halves

Mold halves close around Parison

Plastic solidifies inside mold

Mold opens to get final component

Figure 2: Blow molding [1]

Background: Blow Molding

• Variations [1]:

1.

2.

3.

4.

Injection blow molding

Stretch blow molding

Extrusion blow molding

Reheat and blow molding

Bolded: involved in beverage bottle processing

Background: Recycling

•

•

1.

2.

3.

•

•

‘PCR’: post-consumer recycled

Advantages:

Less amount of waste in landfills

Less carbon footprint than ‘virgin’

Less natural resources needed

Disadvantage: Food residue

Solution: Heat to sterilize,

Use pure PET

Figure 3: Pellets [3] flakes [4] PCR

Fluid Mechanics: Temperature

• PET Tmelt: 250-260 °C [8]

Equation 1: Temperature dependent viscosity

• Viscosity:

Optimize T,

just above

Tmelt, low

enough for

PET to flow

(but not too

easily)

[9]

Fluid Mechanics: Molecular Weight

• PET Typical Mw: ~20-40K g/mol [10]

Equation 2: Temperature dependent viscosity

• Viscosity:

The lower the

MW the less

viscous. PET

critical MW is

unknown

[9]

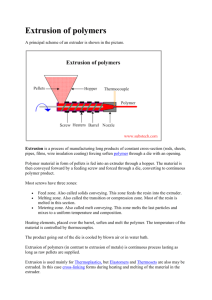

Bottle Processing: Overview

• Simply known as:

Injection Stretch Blow Molding

• Injection (Preform):

Inject hot PET into cavity

• Stretch (Bottle):

Blow preform to get bottle

Figure 4: Preform [5]

Figure 5: Final product [6]

Bottle Processing: Purification

• PET pellets come by railcar

Moved into Silos by Suction

• Dried for 6-10 hours

Rate limiting step for the process

~ 0.2 % Moisture

• Additives

Colorant, Plasticizers, Release Agents

Bottle Processing: Preform

• Injection Stretch Blow Molding:

Summarized in 4 steps

Figure 6: First two steps involved in injection stretch blow molding

[7]

Bottle Processing: Bottle

• Injection Stretch Blow Molding:

Summarized in 4 steps

Figure 7: The rest of steps involved in injection stretch blow molding

[7]

Conclusions

•

•

•

•

AMCOR Makes PET Preforms/ Bottles

Receive PET pellets and dry them

Preforms made via injection molding

Bottles made from preforms by blow molding

References

[1] Manufacturing: Plastic Molding & Forming. Engineer's Handbook. Web.

[2] Blue Baby Rattle Shower Favor Holders. Factorydirectcraft. Web.

[3] Recycled HDPE Resins. Envision Plastics. Web.

[4] PCR PET Flakes Decontamination. Viscotec. Web.

[5] PET Preform Injection Molding Machine: SZ-1600A. Web.

[6] Pepsi Introduces New Shape for Bottle After 16 Years. Designboom. Web.

[7] Injection Stretch Blow Moulding. Plastipedia. Web.

[8] Polyethlene Terephthatate: Melting Point. Web.

[9] Mendoza, J. D., Mat E 453 Lecture, Iowa State University.

[10] Pearl Engineering PEPLEPET B-103C PET Bottle Grade. MatWeb.