SQF 1000 Materials

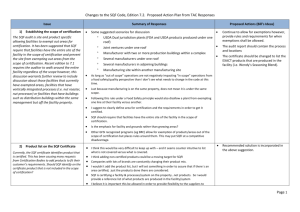

advertisement

SQF Technical Advisory Council Meeting – April 2010 SQF Institute Discussion Topics SQFI Program Updates SQF Product Updates Quickfire Other SQFI Program Updates Program Growth Update on training, on-line training Marketing update Market expansion – Asia / Pacific Certification Body performance RABQSA update Review of scoring / rating solutions Input from group Structure of SQF Program FMI CEO Sam DiCarlo CFO FMI Jill Hollingsworth VP of Food Safety John Schulz SQFI - BD Gary Smith SQFI - TD SQF Registrations – January 09 Total of 1963 registrations Aus / NZ – 1385 N.A. – 322 A / P – 215 S.A. - 15 11% 1% Aus/NZ N.A. A/P S.A. 16% 71% SQF Registrations – January 2010 1% 7% 1% Total of 4257 registrations Aus / NZ – 1902 N.A. – 1968 A / P – 286 Latin Am. – 52 Europe – 14 Other - 35 Now 4890 sites Aus/NZ N.A. A/P L.A. Eur 45% 46% North American CBs within SQF – Number of Registered Sites SGS – 1535 (1) Silliker – 748 (2) NSF – 583 (3) NCSI – 354 (5) GFTC – 147 (6) TUV – 129 (7) SAI Global – 100 (8) AIB – 86 (9) Others - DNV - 48 - Steritech - 37 - SCS - 23 - Eurofins - 3 - Cert-ID - 0 - Intertek (new) - Perry Johnson (new) Eagle – 78 (10) (rank within total SQF CBs – 19 total) US Certifications by FSC by % – April 2010 25 23.8 20.9 20 14.3 15 Food sector cat 11.6 10.1 10 6.5 7 5.9 5 4.1 4.1 4.3 3.2 4.1 2.9 0.5 N = 1159 0.4 1.1 1.1 1.1 1 0 3 4 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 26 27 Growth in SQF Program Overall there has been 117% growth in the program over the last 12 months The number of registered auditors has increased from 128 to over 300 There are now SQF certificates in over 30 countries around the world SQF Budget Performance in 2009 2009 Budget approved was that SQF was expected to lose 400,000 USD Final 2009 budget numbers show SQF actually finished in positive numbers, with some revenue from 2009 actually being attributed to 2010 due to some CBs invoices still outstanding 2010 approved budget has a 60 % increase in revenue • First quarter 2010 update Revenue Model Discussion SQF current revenue stream • 52% from registrations (average $300 per year) • 18% from conference and training (auditor, update) • 11% from on-line training revenue • 9.5% from license fees • 4.0 % from conference sponsorships • 3.6% from PAF downloads Revenue stream from beyond 2010 - ??? Update on SQF Training Since January 2009, there have been • 3,200 Implementing SQF 2000 exams • 316 SQF auditor exams • 242 Implementing SQF 2000 on-line course Training Update SQF 1000 Materials Training Update Upcoming Projects SQF 1000 Materials Training Materials Exam Guidance Document SQF 1000-- Training Materials Implementation Training Materials for SQF 1000 have been developed • PowerPoint • Workbook • Exam Includes food safety and food quality examples for primary producers Need pictures to enhance content Future: Spanish translation SQF 1000-- Exam Developed for 1000 Implementation Course Designed for Consultants, Suppliers, Practitioners Multiple choice – no true/false or negative questions. Example: When developing the food safety plan the producer must ensure A. That at least one critical control point has been identified B. All employees have attended a HACCP certification class C. The customer's quality requirements have been considered when determining critical control points. D. The SQF Practitioner has validated that each critical limit is effective in controlling the identified hazard SQF 1000– Guidance Document Developing General Guidance Document Ready for review by May 5th Need Technical Experts for Animal Handling (sections 5.6, 6.15, and 6.16) Training Update SQF 1000 Materials Training Update Upcoming Projects SQF Training Training Survey Overview Feedback from Participants and Training Centers Training Materials Survey Results-- Overview Course attended: Survey Results-- Overview Overall did you find the course…. Survey Results-- Overview The content was… Survey Results-- Overview The method and style of presentation was… Survey Results Overview The rate of instruction was… Survey Results-- Overview The course prepared me to implement SQF systems Survey Results-- Overview The course exam…. Survey Results– Participant Comments Comments can be classified into 4 Categories Time Materials Instruction Exam Survey Results-- Comments Time • Participants would like more time and extend the Implementing course at least ½ day • The time for the course content should re-structured with emphasis on the Implementation modules. Specifically more time is needed on: SQF Code; Food Quality Plans; Validation and Verification Activities Survey Results-- Comments Materials • Fix typos and grammatical errors • Remove irrelevant information • Include “real world” examples, pictures and documents • Translate in French Survey Results-- Comments Instruction • Online course is a very useful tool • Overall instructors are doing a great job • More interaction/ exercises are needed Survey Results-- Comments Exam • Exam items are tricky • A practice exam would be helpful • Exam items didn’t correspond with the training material SQF Training Training Survey Feedback Updated Training Materials to address comments Translations Updated Training Materials Time Observation: There is not enough time to cover all the information presented. The training time should be extended. Resolution: Reorganize the agenda to emphasize the modules in the Implementing Section. Trim/restructure the “Cost of Quality” and “Implementing SQF System.” Updated Training Materials Example Agenda: 1) Introduction and Overview of the Course- 1 hour 2) The SQF Codes, Food Sector Categories, SQF Vocabulary, Use of the Logo, SQF Practitioner, SQF Consultant – 90 minutes 3) Implementing SQF 2000 Systems – 4 hours Workbook Review – 45 minutes 4) SQF Code- Fundamental Requirements – 90 minutes 5) SQF Code- Pre-requisite Programs – 1 hour 6) Auditing & Certification of SQF Systems: A Supplier Overview – 1 hour 7) The SQF Food Safety Plan – 90 minutes Exercise: Developing a Food Safety Plan 8) The SQF Food Quality Plan – 1 hour Exercise: Developing a Food Quality Plan Updated Training Materials Materials Observation: There are some clerical errors in the documents. When practical examples are used in the training course the participant can better understand how to apply the concepts Resolution: Fix all typos and grammar errors. Simplify some of the “bulky” slides. Include “real world” examples in the notes section as they apply to the code. Create an appendix that includes sample documents (Policy Manual, Pre-requisite programs). Updated Training Materials Instruction Observation: Some of the information presented was not current. While the majority of instructors were rated high there were some instructors that were not rated favorably. Resolution: Audit training courses and develop a train the trainer course to keep trainers updated on the code revisions. Include a module on Quickfire Updated Training Materials Quickfire Module Designed as quick introduction and to be used as a long term reference Topics: - What is Quickfire and how do I use it - How to register your site on Quickfire - ICIX - The buyer module - How to add a buyer - How to access buyer information - User guides/videos Updated Training Materials Exam Observation: The exam questions are tricky and don’t pertain to the course material. Resolution: Develop a new bank of test questions that are relevant to the course and the participant. Include a practice exam and/or questions dispersed within the training materials. Training Update SQF 1000 Materials Training Update Upcoming Projects Upcoming Training Projects Translations • Revised SQF training materials to be translated in Chinese, Japanese, and Spanish (French?) Auditor Training • Revisit training materials • Develop new bank of audit questions (include a practical exam as part of training class?) SQF Marketing Update Working with marketing firm Merrill and Associates on marketing projects • Short term – March/April newsletter • Market research – surveys from Suppliers CBs Retailers • Marketing materials • Review of SQF website Activities in Growth of Asia / Pacific Market Conference in China, November 2009 Auditor course in China, April, 2010 Other activities / potential • Brazil • Mexico • Central America • Europe Certification Body Performance Monitoring capabilities limited from Quickfire • Currently able to do report review and monitoring of audit group management • Feedback provided to CBs Have requested more reports from Quickfire for future monitoring Have been in close contact with both accreditation bodies with reports from recent assessments and concerns One Certification Body has been delisted due to monitoring activities CB Compliance Data Reality – very limited reporting capability out of Quickfire presently Management of Audit Groups – audit groups closed within 45 days after due date North American CBs – (SQF average 93.7) • • • • • • • CB A – 100% CB B – 99% CB C – 97% CB D – 95% CB E – 93% CB F – 85% CB G – 78% - CB H – 75% - CB J – 70% - CB K – 56% - CB L – 50% RABQSA Performance Since Sept 1, all applications have been handled electronically by RABQSA Applications received – 263 applications total • 196 auditor applications • 58 consultants • 9 trainers Turn around time of applications now at 7 business days Concerns – • 9 trainers applications only –14 total trainers registered Rating Issue Issue: Due to the scoring system of SQF audits, ratings for all audits are skewed very high Potential solution: • Rework rating formula for determination of rating • Increase weighting of non-conformances Fix will be incorporated with new PAFs for SQF 2000 in May, 2010 Example of Rating Issues Example: site with 2 majors, 15 minors, and 10 OIP – surveillance audit needed • Currently rates – 96.0% E rating • Reworking formula – 84.1% C rating • Weighting of N/C – 77.6 % C rating Weighting of N/C proposal • OIP: -1 point • Minor: -10 points • Major: - 50 points • Critical: -100 points Weighing of N/C chosen by AP group, show both scores for a year Implement by June 1st, 2010 Discussion Topics SQFI Program Updates SQF Product Updates Quickfire Other Multi-site Certification Some confusion on multi-site certification, clarification from TAC needed • Audit protocols Every 6 months central site audited, sample of sub-sites Full document audit done at one sub-site Full audits done by central site of each sub-site annually Only certificate received by central site • Questions Should sub-sites each receive a certificate from CB How should a document review audit of sub-sites be conducted SQF 1000 Update 5th Edition Final version was released Sept 1st, 2009 Minor revisions in Jan, 2010 Updates • Transition over March 1, 2010 • Minor revisions to ensure GFSI recognition • Level 2 and 3 PAFs available Update on Competing Produce Standards Freshcare • Given growth of Fresh Care in Australia, we are meeting with them to discuss collaboration options • Given status of 1000 and declining market share, what should we attempt to accomplish United / LGMA / FL Tomato • No push for GFSI certification within produce industry in North America • Less robust standards being developed and accepted by US buyers United Produce Standards Developing a produce standard with customer buy-in and participation that can be used by anyone. The goal isn’t to create a new standard but use the content from existing standards to create a “harmonization” approach. Currently have 39 out of 60 standards developed. Target date for completion is October 2010 Next big discussion is on how the developed standard will be implemented and sustained. Future of SQF 1000 SQF 1000 market share eroding quickly Freshcare in Australia becoming dominant produce standard In North America – produce industry has not embraced 1000, GFSI recognized many primary produce standards Actions / Strategies to move forward SQF 22000 SQF 22000 has been submitted to GFSI for benchmarking • Using session 5 and 6 from SQF 2000 standard, with ISO 22000 as the foundation for food safety management Accreditation will have to include 17021 as an scheme, CB criteria document must be updated Reason – North American, Asia/Pacific option for 22000, easy access to SQF CBs Status – initial benchmarking, additional work needed to complete benchmarking, no activity until July, 2010 SQF Ethical Sourcing Module Module built combining the SQF modules (RSP, REP), retailer standards and the Global Social Compliance Program (GSCP) To be combined with SQF certification audit Expected to be 1 additional audit day Auditors will be required to be SQF registered and undergo an additional training session on ethical sourcing module and on-line exam • Webinar April 28th • Classroom May 7th - Chicago Solution for Sustainability – SQF Modules Responsible Social Practices Responsible Environmental Practices Ethical Sourcing Food Defense Guidance Documents for SQF General Processing Requirements Produce Packing House (FSC 4) Shell Egg (FSC 12) Transport and Distribution (FSC 25 & 26) Packaging (FSC 27) To begin in Q1 of 2010 • Dairy (FSC 10) • Brokers (FSC 35) Guidance Document Approvals Needed Packaging Produce Packinghouse Ethical Sourcing Other Potential New Products Ethical sourcing training and on-line training Animal welfare – module around humane handling of animals, chicken, beef, pork, lamb Aquaculture module SQF branded products Quickfire Support Solution SQF Quickfire Support Personnel • Australia – part time, 20 hrs per week • US – part time, 20 hrs per week (ON HOLD) Dedicated to providing Quickfire support to Industry • Suppliers • CBs Will be interacting with Muddy Boots directly when there are issues they cannot address Implementation April 1st, 2010 in Australia Webinars, user guides, Muddy Boots training Quickfire Discussion Current status – SQF has expressed major concerns to Muddy Boots over usability of system, report capabilities, interface requests, responsiveness and engagement of SQF team in communication and strategy Concerns – Have we asked them to do too much? • Reality – system not built to run a certification program, very limited customization to SQF needs Future – reviewing options on reporting capabilities with other service providers, contracted objective review with usability of system for customer interface SQF Conference, August 2010 In conjunction with AFS HACCP conference in Melbourne Review of agenda and speakers Awards and sponsor updates GFSI Update Many standards globally seeking GFSI recognition • Primus, Global GAP, FSSC 22000, Syngery 22000, Red Meat Standard recognized • Concern expressed to GFSI on number of recognized standards growing • GFSI not concerned with number of standards, want as many as possible, more concerned on costs of GFSI certification audits and expansion into emerging markets 6th Edition of the GFSI Guidance Document set for July, 2010 release SQF working with GFSI Accreditation committee on Witness Audit Recognition Program with CB association (Food Safety Forum) Other Discussions Sprouts / Mushrooms to be SQF 2000 ICIX integration Use of the SQF buyer module