Design - Manufacturing - Mechanical Component

advertisement

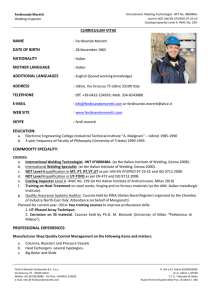

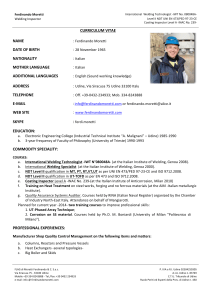

nuova tubital Società Cooperativa per Azioni Design - Manufacturing - Mechanical Component - Oil Refinery Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ ISO 14001 ASME STAMP ASME STAMP ASME STAMP _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 Name of Company: Nuova Tubital Soc.coop.p.A. Phone Number : +39 041 2587011 Via delle Querce, 45 Fax Number : +39 041 2587040 30175 MARGHERA (VE) E-mail : mail@nuovatubital.it ITALY Company Location: • Location of NuovaTUBITAL very closed to Marghera’s Port, makes transportation and shipment of heavy & large equipment very easy. Manufacturing Program : • NuovaTUBITAL designs, engineers and manufactures a wide range of equipment for oil, gas, chemicals, high vacuum, cryogenics, power generation industry. Our fabrication experience covers standard and low temperature Carbon Steels, Stainless Steels, Clad Steels, Nickels, Inconels, Monels, Hastelloys, Aluminium Design and Engineering • Mechanical calculations in accordance to all available codes from ASME to VSR/VSG (Italy), PD-5500 (U.K.), AD-2000 (Germany), CODAP (France), EN-13445 (European Standard), GB150 (China), Indian Boiler Regulation, TEMA, STOOMWEZEN (Netherlands. • Local stress Analysis on Nozzles under external loads ( WRC107, WRC297) • Fatigue analysis on heat exchanger and pressure vessels under thermal and mechanical cyclic loads. • 2D & 3D FEA ( Finite Element Analysis ) • 2D & 3D CFD ( Computational Fluid Dynamics) • Thermal and mechanical calculation of heat exchanger (HTRI) • Finite Element Calculation Samples • Software for Mechanical Calculation of pressure vessels and heat exchanger Facilities and Factory Equipments Automatic flame and plasma cutting machine Heat Treatment furnace Bending Machine : up to 180mm x 3000 Cranes : 40 Tons max Each Clean area Vertical Turning lathe machines (4500mm diameter x 3500mm ) Sandblasting and painting area Local Heat Treatment • • • • • • 100000 hours per year production capacity 20 qualified welders and operators 7000 sqm of shops-pace out of a total surface of 64000 sqm 400 tons for the heaviest equipment manufactured 7000 mm for the largest equipment manufactured 40 average number of employees Facilities: • • • Heat Treatment furnace Sandblasting and painting area Clean area for stainless steel equipments Main Equipments: • • • • • • Cold rolling machines (70x3500mm); (180x3000) Vertical Turning lathe machines ( 4500mm diameter x 3500mm ) Automatic flame and plasma cutting machine ( 300 thk. Max ) Manual and automatic welding machines : GTAW, SMAW, SAW, GMAW, FCAW, ESW Tubes to tubesheet automatic welding machines Tube expanding machines Major Customers • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • ALSTOM POWER AGIP AIR LIQUIDE ALFA LAVAL PACKINOX API BCC BORSIG CHINA PETROC. ENG ENICHEM ESSO GROUP FERTINITRO FFC FOSTER WHEELER HALDOR TOPSOE KOCH KVAERNER GROUP JACOBS JORDAN PERTOLEUM LINDE LURGI NUOVOPIGNONE PPTA PROSERNAT SAIPEM SNAMPROGETTI SOLVAY STATOIL TECHNIP TECNIMONT UOP HONEYWELL CAPABILITIES (facilities, equipments, …) AND SUBCONTRACTED WORK Upadated on: November 2013 A. Facilities Size Information Total Area under roof 6500 m2 YES Climate controlled area NO Fabrication area 6000 m2 Storage area 500 m2 Fabrication area n.a. Storage area 16 m2 Fabrication area 500 m2 Storage area 17000 m2 Total usable area outside 17500 m2 Work performed outdoors Pickling and passivation Largest door size material can move through 8.5 x 8.5 m Largest equipment size transportable by road L x O.D.[m] – Weight [ton]: 50 x 3 m – 500 ton 15 x 7 m – 500 ton Production area information Number of Production Bays Bay Number Length x width Number of Cranes 2 1 2 113 x 30 m 65 x 33 m 3 2+2 Separate Bay for Non-carbon steel work Crane size Type of Crane 40 ton/each Bridge crane 10+5 ton/each Bridge crane Height under hook 13 m 10 m Part of bay 1 or bay 2, according to production needs YES NO Testing facility information Radiography viewing room at the fabrication shop Bend testing for welder qualification YES NO YES NO Protected bunker for radiography YES NO Tensile and charpy testing for weld procedure qualification YES NO Painting facility information Capability to blast and paint at shop location Blast Area: Painting Area: Indoors Indoors YES NO Dimensions Dimensions 6 x 7 x 16 m 6 x 7 x 16 m Outdoors Outdoors 6 x 7 x 15 m under extensible Dimensions roof max 50 m(ind+outd) 6 x 7 x 15 m under extensible Dimensions roof max 50 m(ind+outd) B. Type of Work Type of work typically performed Design Fabricate Comments Pressure Vessels Drums Towers Heat Exchangers Shell & Tube Hairpin n.a. Thermal By sub-supplier Skids (also what applies below) Modules (also what applies below) Pipe Spools Pipe Bending By sub-supplier Structures By sub-supplier Platforms, ladders, handrails By sub-supplier Electrical n.a. Cable tray n.a. Conduit n.a. Heat tracing n.a. Instrumentation: n.a. Control Panels: n.a. Refractory: By sub-supplier C. Materials Carbon steel Clad steel High Nickel Titanium Low temp carbon Austenitic stainless Hastelloy 10-14 US standard gauge sheet Chrome- moly Duplex stainless Aluminum Perforated sheets Other Copper alloy and inconel weld overlays D. Equipment Metal Processing Equipment List any limitations Cutting - Plate Automatic flame and plasma cutting machine 300 mm max (plasma cutting) Cutting- Pipe Automatic flame and plasma cutting machine Cutting- Sheet metal Automatic flame and plasma C.S.: 300 mm max S.S.: 80 mm max Punching- Sheet metal Press Max. 100 bar Forming - Sheet metal By sub-supplier Bending- Pipe By sub-supplier Beveling Automatic flame and plasma cutting machine Grinding Automatic grinding machine Drilling By sub-supplier Machining Vertical lathe Head Forming Maximum diameter & thickness Cold condition: by sub-supplier Hot condition: by sub-supplier Shell Rolling Maximum thickness and width Cold condition: 180 mm x 3000 mm 70 mm x 3500 mm Hot condition: 180 mm x 3000 mm Max dia x height [m] 4.5 x 3.5 m Welding Equipment Process Quantity Max. capacity 6 400 A SAW- boom type 5 column 2 orbital 1000 A 500 A SAW- propelled 1 tractor 1000 A 500 A Other Quantity Max. capacity Process GTAW 20 7 GTAW pulsed 500 A 400 A GMAW- pulse SMAW 43 600 A FCAW 15 GMAW- spray 15 Heat Treating Furnace Permanent facility or temporary: Permanent Fired by gas or electric: gas Automatic Control or Manual: automatic Size and weight limits: 7 x 7 x 18 m Maximum Temperature: 1000°C Method of Loading: wagon In use since: 2001 Products • Heat Exchangers: Carbon steel , Stainless Steel, Carbon steel claded Heat exchanger Special Types: Rod Baffles Medium pressure H.E. for fertilizer plats PTA plants heat exchanger H.E. for offshore equipment Gas-Gas heat exchangers • Basket ammonia converter internals for reactor Material: SA240 g. 321 + Inconel 600 • TLX Exchangers: Carbon steel , Low alloy steel TLX exchanger • Platforming reactor and Regeneration Towers: Low alloy steel Platforming reactor Material : SA 387 gr.11 cl.2 Weight : 201,6 ton Customer: Nuovo PIGNONE Regeneration Tower Material : Weight : Customer: ASME SB 409 UNS 08810 7.5 ton Nuovo PIGNONE • Columns: Carbon, Low Alloy steel and stainless steel Columns Largest equipment manufactured: Length 44150 mm Diameter 2532 mm Weight 54.5 ton • Drums & Storage vessels: Wide rage of drums and vessels made by Carbon, Low Alloy steel and stainless steel material. • Scrubbers –Reactors Special reactors manufactured in Aluminium material – Max. thickness 50mm Certifications • ASME symbol “U” - Certificate of authorization Scope – manufacture of pressure vessels • ASME symbol “U2” - Certificate of authorization Scope – manufacture of pressure vessels • ASME symbol “S” - Certificate of authorization Scope – manufacture of steam boilers • The National Board - Certificate of authorization Scope – manufacture of steam boilers, pressure vessels and other pressure retaining items • TUV certificate Scope – manufacture according to AD2000 – HP 0 • UNI EN ISO 9001:2008 - Quality management system Scope – manufacture of pressure vessels and heat exchangers • UNI EN ISO 14001 - Environmental management system Applied – manufacturing of pressure vessels and heat exchangers • OHS 18001 :2007 - Health and Safety management system Applied – manufacturing of pressure vessels and heat exchangers • SQL - P.R.C. of China Authority Scope – manufacture of stationary pressure vessels • MKE - Certificate of Manufacture Registration of Cylinder Scope – manufacture of Refrigerator and Specific Equipment Nuova Tubital soc.coop. per Azioni N.TUBITAL Società Cooperativa per Azioni A BRIEF INTRODUCTION Company located very close to Venice Port Started activity in 1954 and was re-organised in 1983 .The company is specialised in 1.- design et manufacture of Heavy -Duty equipments for Oil Refinery -Petrochemical Plants-Power Stn. ( Reactors , Pressure Vessels , Gas column ,Heat exchangers , Gas recuperators ,Compressor nozzles, Methyl acetate column ,skid x co2 removals \ Storage tanks for Oil & Power industry etc…. ) Chemical plants et Marine Construction ( Shipping hulls et metal parts.) Food processing and water -industry. After detailed client specs. NT associate engineers develop calculation's et drawings. Equipment for desalination plant 2.- Production area is very consistent and divided as follows Covered area of 7000 square-meter. Total area 24.000 sqm. \ G.Furnace ( 7x7 x 18 )m. for heat treatments up to 1000 deg.C plus sandblasting and Painting Equipment ( 7x7 x 16 )m. The company is employing around 80 specialist all together . Many of them are company share-holder and self-employed. Company turn-over many million usd. - have an expansion plan , but never do more unless have the means to control-it ( this means that our specialist -each one - has a special training and knowledge , completed with many years of experience .) The company use latest hi-tech computer technology and keep its many year experience in designing and improving system et equipments. 3.- Code and Rules used for Designing and Construction are : ISPESL ( ANCC:VSR,VSG,M,S ) /ASME SECT.VIII DIV.1 / ASME SECT.VIII DIV.2 / ASME SECT.1,SVDB TEMA / STOOMWEZEN / PS 5500 / CODAP / API 650 -614-620 / Uniform Bldg.Code / AD 2000 Merkblatter - PED ( DIR.97/23/CE ) Our Office provide last updated edition of a.m. codes, and to apply them , we do use computer calculation programs , verified and updated to last current editions. For Finite Elements analysis the " SUPERSAP " computer program is used. Quality Certificate are \ ISO 9001 \ISO 14001 / OHSAS 18001 - ASME U - U2 & S STAMP – TUV HP0 – SQLC licence to export to the People Republic of China, Approval to export in Poland, U.K. And many other Countries.(Khazakstan - Tengizchevroil , etc.. ) Our main Clients are major Oil \ petrochemical world known companies Major Clients \ SNAMPROGETTI - ENI – NUOVOPIGNONE - JOHN BROWN - FOSTER WHEELER ENERGY LTD. - UOP Belgium – BORSIG - ESSO – ALFA LAVAL PACKINOX - CHEVRON - LINDE Germany , STATOIL Norway - AXSIA ( UK ) - UOP LLC ( USA ) – PARAGON LITWIN ( FR ) - AIRLIQUIDE ( FR ) - FFC (PK) - JORDAN PETROLEUM - KOC ( Kuwait Oil Co. ) - TAKREER ( Abu Dhabi ) and ADCO ITALIMPIANTI (Desalt. plant equipment. ) for KT & ABU DHABI **** HOW TO CONTACT US \ Factories \ NUOVATUBITAL Soc.Coop ar.l. Via delle Querce , 45 30175 Marghera ( Venezia ) -ITALY Tl. +39 .041 .25870 11 Fx. +39 .041 .25870 40 Email mail@nuovatubital.it Web www.nuovatubital.it Chairman rev. 14 ORGANIGRAMMA AZIENDALE ORGANIZATION CHART DIR Presidente President International Sales Division VND Resp. Commerciale Sales Manager Coordinatore CND / NDE Coordinator RGQ Resp. Gestione Qualità Quality Management Vice Direttore Vice President Ufficio vendite Sales department Medico Doctor CQA Controllo Qualità Quality Control Coordinatore di saldatura Welding coordinator Rappresentante dei Lavoratori per la sicurezza (RLS) H&S workers' representative Preposti alla sicurezza H&S Worker's Coordinator Incaricati Sicurezza e Ambiente HSE Assistant PRD produzione RSPP Responsabile del Servizio di Prevenzione e Protezione (RSPP) Health & safety mgr. Responsabile del Sistema di Gestione della sicurezza (RSGS) Responsabile del Sistema di Gestione Ambiente (RSGA) HSE system mgr. AMM + PER Amministrazione personale administration human resources CDG Finanza/c.d.g. Finance and controller Uff. Sicurezza e Ambiente HSE dept Antincendio Fire Team Pronto Soccorso First Aid ACQ + MAG Ufficio Acquisti, Magazzino, Logistica Purchasing, warehouse, logistics dpt Funzioni aziendali del Sistema di Gestione Ambiente e Sicurezza HSE department PRD Produzione Production AP Assistenti di produzione Foreman assistant data: 09/09/2013 PM capo commessa, programmazione commessa, welding engineer commessa, piani di taglio project mgr, planning, welding eng., nesting PRG Ufficio Tecnico / Technical Dept. Elaborato: M. Vezzani Approvato: M. Bragato REFERENCE LIST Job Client Year Country, Place - Plant Project ***** Some of Main equipments Manufactured By NuovaTUBITAL ***** Size Empty Material & Wall Thk. Service Dia. x Lenght Weight Shell / Head \ mm. \ 1286 John Brown Snamprogetti Nuovo Pignone 1534 Linde 1536 Snamprogetti 1546 Snamprogetti 1545÷47 Snamprogetti 1545÷47 Snamprogetti Linde 1460 Nuovo Pignone 1512-1484 Nuovo Pignone 1500 Nuovo Pignone 1594 Sovimp 1557 Technimont 1621 API Ausimont 1655 UOP 1670 UOP 1703 Linde 1704 Agip VE 1739 Statoil 1751 Snamprogetti 1741 Linde 1752 Statoil 1800 Linde 1805 UOP 1820 Linde 1825 Raffineria Milazzo 1807 Nuovo Pignone 1811 Nuovo Pignone 1836 Agip Taranto 1952 UOP 1957 UOP 1864 UOP USA 1866 Statoil 1868 Sovimp 1867 Linde 1872 UOP 1887 Jordan Petroleum 1890 Paragon 1894 Techint 1907 S.Marco Gas 1911 Air Liquide x UOP 1913 UOP 1914 Techint 1921 JQCF China 1877 Snamprogetti 1879 Snamprogetti 1924 FFC 1925 Agip 1995 1997 1998 1998 1998 1998 1998 1998 1998 1998 1998 1999 1999 1999 1999 1999 1999 2000 2000 2000 2000 2000 2001 2001 2001 2001 2001 2001 2001 2002 2002 2002 2002 2002 2002 2002 2002 2002 2002 2002 2002 2003 2003 2003 2003 2003 2003 2003 2004 2004 Indonesia China Italy China - NANJING Argentina, Bahia Blanca Venezuela - Fertinitro Venezuela - Fertinitro Venezuela - Fertinitro Hungary, Budapest China - Daqing Proj. China, Dagang Beijigin Italy, Firenze Turkey China, ShangaI Phoenix Italy Italy Greece Netherland China, Jilin Italy, Venezia Denmark Italy, Ferrara - Enichem Italy, Marghera Denmark Iran - MARUN Iran Iran, Asaluye Italy, Milazzo China Dushanzi - CPTDC USA, Louisiana - Orion Italy, Taranto Austria UK, Wales - Texaco Bulgaria Denmark Turkey Norway - Kollness Germany, Dormagen Jordan, Amman Italy Italy, Taranto - ENI Italy China, Caojing Croatia, Rijka Italy, Marghera - ENI China Brazil - Rio Polimeros Poland - POLSKI Pakistan Italy, Marghera - ENI 11500x33300 3030x6538 690x4000 1700X5730 1700x18400 2150x10600 965x13820 2362x9000 2590x8770 600x4500 600x4500 3000x20000 3760x9000 900x2000 3200x30000 2100x18200 1546x7200 1700x9000 1622x6200 4800x26550 1650x5400 1220x3900 1200x4600 800x4080 3500x9300 1366x5500 2700x6700 3000x3400 700x1500 2600x45000 1500x9800 2841x10600 2300x9500 1220x8508 750x12000 3120x6270 2468x14550 2280x9075 2800x9200 2500x44100 1050x8500 4200x30300 2344x7700 2050x8354 919x4300 3030x6538 2750x12000 1100x4150 2500x8500 4500x26200 Type Applicable Code Ton. 172 14 1.7 11 42 16.6 7.5 17.7 21.6 2-5 2-5 20 27 2÷5 55 20 7.1 9.9 13.7 88 14.4 4.5 3.3 4.65 28.7 3.8 17 40 10 201.6 11.5 33.5 25 8.2 8.5 18 65 37 17.2 54 15.9 70 14.5 10.4 2.5 14 40 5 39 45.6 S.S. Aluminium C.S. 10Ni 14 DIN 17280 C.S. S.S. S.S. C.S. C.S. C.S. C.S. SA 240 Ty321 + Inconel 600 Aluminium S.S. C.S. + S.S. ASTM B 168 UNS6600 C.S. C.S. SA 203 gr.D C.S. C.S. S.S. S.S. C.S. SA 387 Gr.11 cl.2 C.S. C.S. C.S. C.S. SA 387 Gr 11 cl.1 C.S. + SS 316L P355NH EN 10028/3 C.S. SA 240 Ty316Ti C.S. Aluminium DIROS 500S P355NH EN 10028/3 C.S. P275NH EN 10028/3 SA 387 Gr.11 cl.2 P355NL2 EN 10028/3 C.S. C.S. C.S. + Monel 190 Aluminium C.S. and S.S. C.S. C.S. + SS 316L C.S. 10/24 45/47 P.T.128 43/43 50/56 22/22 12 31/31 45/45 10-15 10-15 30-60 50/50 8÷15 20+3 15/17 27/31 22/27 58/57 27/14 41/40 13 21/23 32/27 52/28 17/22 38 16/22 10 34/55 20+4 41/44 50/66 10/8 15/15 50/50 66/40 60/75 24/35 16 22 21 28/38 25/30 P.T. 125 15/47 45 34 42,5+3 /42+5 20/25 Silos Reactors Tube Bundle Adsorber Vessel Vessel Heat Exchanger Vessel Reactors Heat Exchanger & Volume Heat Exchanger & Volume Ammonia Converter Internals Reactors Pressure Vessels Column Reactors Adsorber + Drum Adsorber Adsorber GPL Vessel Drum Vessel Vessels Vessels Reactor Adsorber + Drum Vessels Column Volume bottle Platforming Reactor Column Adsorber + Drum Adsorber + Drum Regeneration Tower Stripper Reactor Vessels Adsorber + Drum Adsorber Column Heat Exchanger GPL Vessel Adsorber + Drum Adsorber + Drum Tube bundle Reactor Pressure vessels & Columns Suction Drum Reactor Column Drum Reactor Tube Bundle Pressure Vessel Pressure Vessel Pressure Vessel Heat Exchanger Pressure Vessel Reactor Pressure vessel + Heat Pressure vessel + Heat Reactor Reactor Pressure Vessel Column Reactor Pressure vessel + Drum Pressure vessel Pressure vessel Pressure vessel Drum Pressure vessel Pressure vessel Pressure vessel Reactor Pressure vessel + Drum Pressure vessel Column Pressure vessel Reactor Column Pressure vessel + Drum Pressure vessel + Drum Column Column Reactor Vessel Pressure vessel + Drum Pressure vessel Column Heat Exchanger Pressure vessel Pressure vessel + Drum Pressure vessel + Drum Tube bundle Reactor Pressure vessel + Column Drum Reactor Column ASME VIII Div. 1 ISPESL - VSR ISPESL - VSR AD-MERKBLATTER ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 AD-MERKBLATTER ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 AD-MERKBLATTER ASME VIII Div. 1 ISPESL - VSR ISPESL - VSR ASME VIII Div. 1 Stoomwezen ASME VIII Div. 1 ISPESL - VSR ASME VIII Div. 1 ISPESL - VSR ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR AD-2000 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 AD-2000 AD-2000 AD-2000 ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR REFERENCE LIST Job Client Year Country, Place - Plant Project ***** Some of Main equipments Manufactured By NuovaTUBITAL ***** Size Empty Material & Wall Thk. Service Dia. x Lenght Weight Shell / Head 1926 1929 1931 1932 1937 1940 1943 1912 1912 1912 1912 1912 1912 1912 1912 1912 1912 1912 1912 1912 1930 1941 1942 1948 Snamprogetti Air Liquide PRL Pakistan Air Liquide PTA Pakistan UOP UOP x Air Liquide ENI ENI ENI ENI ENI ENI ENI ENI ENI ENI ENI ENI ENI JQCF China Technip Technip Termokimik 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2004 2005 2005 2005 U.A.E. Abu Dhabi, BUBelgium - BASF Pakistan Italy, Priolo Pakistan Italy, Sannazzaro de China Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI Italy, Marghera - ENI China, Jilin - Qifeng Italy, Ancona - API Italy, Ancona - API Saudi Arabia \ mm. \ 1800x6460 1750x23730 2515x6500 1300x6450 744x3300 2040x8110 2344x7700 810x6100 612x6100 862x6100 812x6100 862x6100 862x4880 812x6100 765x6100 500x3660 1050x6500 1050x6500 1050x6500 790x4000 650x3000 21500x9200 2000x9300 2700x5900 Ton. 9.3 54 35.5 6.1 0.7 13 14.5 1950 API 2005 Italy, Ancona - API 1600x25000 1951 PPTA 2005 Pakistan 1500x21150 1957 1960 1969 1974 UOP Bahrain Gianazza Air Liquide BCC for Quatar Petroleum Technip Linde Polimeri Europa Borsig Simic Snamprogetti & Lavalin Linde Snamprogetti & Lavalin Borsig 2005 2005 2005 2005 2005 2005 2005 2006 2006 2006 2006 2006 2006 Baharin China France - H2 Lavera Qatatr - Fahahil Stripping Iran - Kharg Ethylene Plant India - Jamnagar -2 Italy, Marghera Saudi Arabia, Rabigh Greece Canada, Canadian Horizon Saudi Arabia, Jubail Canada, Canadian Horizon Saudi Arabia, Jubail - 3302x11400 1600x46550 1400x11150 1778x19174 1370X8741 3000x11570 1500x9500 1107x116133 3800x40370 2200x7650 6050x26750 3100x47810 1271x13408 Prosernat 2006 Iran - DARQUAIN 1942/945x8457 2012 Snamprogetti 2006 17700x850 2012 Snamprogetti 2006 2012 Snamprogetti 2006 2012 Snamprogetti 2006 1991 1992 1998 2000 2002 2005 Italy, Sannazzaro de Burgondi Italy, Sannazzaro de Burgondi Italy, Sannazzaro de Burgondi Italy, Sannazzaro de Burgondi Type Applicable Code 2.5 36.5 35.5 52.5 C.S. + INCOLOY 825 C.S. SA 387 Gr.11 cl.2 + SS 347 SA 387 Gr.11 cl.2 SA 240 UNS S31803 C.S. C.S. C.S. C.S. + SAF2507 C.S. + SS 347 C.S. + SS 347 SA 387 Gr.11 cl.2 + SS 347 SA 387 Gr.11 cl.2 + SS 347 C.S. + SS 316L C.S. + SAF2507 C.S. + SS 316L SA 387 Gr.11 cl.2 + SS 321 SA 387 Gr.11 cl.2 + SS 321 P355NH EN 10028/3 C.S. C.S. and S.S. SA 387 Gr.11 cl.2 C.S. + SS 316L S.S. 20+2,5 /17+2,5 27/23 51+3/50+3 25/15 8 30/40 28/38 12/12 12/10+3 16/16+4 16/16+4 14+4/14+4 14+4/16+5 12+4/12+4 19/10+3 10/12+4 22+3 22/20+3 23/20 20/16 12 81/42 77+3/38+3 47/47 Vessels Vessels Reactor Reactor Degasser Adsorber + Drum Adsorber H2S/Oil H2S/H2O H2/H2S H2/H2S H2/H2S H2/H2S H2S/H2O H2S/H2O Gas / Gas Desulph. BEU Desulph. BEU Desulph. BEU Desulph. AES Heat Exchangers Vessels Vessels Filters Vessel Vessel Reactor Reactor Pressure vessel Pressure vessel + Drum Pressure vessel Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Pressure Vessel Pressure Vessel Pressure Vessel ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR ISPESL - VSR / PED ISPESL - VSR / PED ISPESL - VSR / PED ISPESL - VSR / PED ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 20 C.S. + SS 316L 37+3 column SOUR SERVICE Column ASME VIII Div. 1 23 C.S. + S.S. 12/25 Column + Exchanger Column + Heat Exchanger ASME VIII Div. 1 42.6 82.5 15 39.6 47 35 24.5 37.9 260 9.7 129 67.5 52 C.S. C.S. + SS 316L SA 387 Gr.11 cl.2 C.S. C.S. SA 387 Gr.11 cl.2 C.S. C.S. C.S. + SS 304L C.S. C.S. C.S. + Monel C.S. 48/58 38+3 27/15 24/18 81 39 66/64 57 68+3 / 68+3 14/14 29/27 15/ 9+3 69 Adsorber + Drum Column Reactor Propane Chiller Secondary & Tertiary TLE HT -Shift- Reactor Steam Drum Boiler Feed Water Preheater Column Pressure Vessels Column Column & Pressure Vessels Boiler Feed Water Preheater ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div.1 + TEMA R ASME VIII Div.1 + ASME I ASME VIII Div. 1 ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 18.5 C.S. + INCOLOY 825 21 Vessels and heat exchangers Pressure vessel + Drum Column Reactor Pressure vessel Heat Exchanger Reactor Drum Heat Exchanger Column Pressure Vessel Column Pressure vessel + Column Heat Exchanger Pressure vessel + Heat Exchanger 125 C.S. + SS 304L 21 + 3 Columns Column 21400x711 C.S. + SS 304L 11 + 3 Columns Column 21400x711 C.S. + SS 304L 7+3 Columns Column 38000x1500 C.S. + SS 304L 19 Columns Column ASME VIII Div. 1 ISPESL - VSR, ASME VIII-1 + PED + ATEX ISPESL - VSR, ASME VIII-1 + PED + ATEX ISPESL - VSR, ASME VIII-1 + PED + ATEX ISPESL - VSR, ASME VIII-1 + PED + ATEX REFERENCE LIST Job Client Year Country, Place - Plant Project ***** Some of Main equipments Manufactured By NuovaTUBITAL ***** Size Empty Material & Wall Thk. Service Dia. x Lenght Weight Shell / Head 2012 Snamprogetti 2006 2012 2013-15 1988 2019 2035 2020 2021 2022 2024 2026 2039 2041 2053 2055 SnamProgetti Linde Snamprogetti Koch Heat Transfer Linde Air Liquide SnamProgetti Sud Linde Koch Heat Transfer SnamProgetti Sud Borsig Koch Heat Transfer FFC BCC 2006 2006 2006 2007 2007 2007 2007 2007 2007 2007 2007 2007 2008 2008 2064 Air Liquide 2008 2066 2071 2074 2079 2082 2095 2095 2096 2101 2102 2110 2118 2126 2128 2131 2132 2141 2157 2153 2158÷60 2155 Tozzi Sud Koch Heat Transfer Alfa Laval Packinox Borsig BCC Koch Heat Transfer Koch Heat Transfer Koch Heat Transfer Alfa Laval Packinox Alfa Laval Packinox Alfa Laval Packinox Brembana x Conoco Phillips Alfa Laval Packinox Sofinter Macchi Alfa Laval Packinox Termokimik Alfa Laval Packinox YARA Italia SAIPEM France Alfa Laval Packinox Zanon x Ammonia Casale 2008 2008 2008 2008 2009 2009 2009 2009 2009 2009 2009 2009 2009 2009 2009 2009 2009 2009 2010 2010 2010 2158 Alfa Laval Packinox 2010 2160 Alfa Laval Packinox 2180 2190 Applicable Code Ton. \ mm. \ Italy, Sannazzaro de Burgondi Italy, Sannazzaro de India - Jamnagar T5 T6 T7 Venezuela, Superoctanos China, Dushanzi Morocco Samir Belgium - Jupiter 2 Italy, Taranto India - Jamnagar T8 USA, Louisiana - Westlake Italy, Taranto Iran - Mideast China, Sichuan Pakistan - FFC Plant - III Qatar - MESAIEED NGL-2 Portugal - ESTERREJA HYCO 3 Project India - KG-D6 Block Field Morocco - Samir Refinery USA, Lakes Charles Pakistan - ENGRO Qatar - Qatar Petroleum Pakistan - ENGRO Pakistan - ENGRO Pakistan - ENGRO India, Kochi Thailand - PPT Aromatics Iran - Tabriz Oil Ref. Co. Germany, Wilhelmshaven Mexico - Tula Singapore India - Bathinda Saudi Arabia, Shoaiba Chile - ENAP Bio Bio Italy, Ferrara Algeria China, Sichuan - ISOMAR UK, England - KEMIRA Type 32400x4000 C.S. + SS 304L 33 Columns Column Column Reactor Column Heat Exchanger Drum Reactor Column Reactor Heat Exchanger Pressure Vessel Heat Exchanger Heat Exchanger Pressure Vessel Pressure Vessel ISPESL - VSR, ASME VIII-1 + PED + ATEX ISPESL - VSR ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 EN 13445 ASME VIII Div. 1 ASME VIII Div. 1 EN 13445 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div.1 - U Reactor ASME VIII Div. 1 Pressure Vessel Heat Exchanger Heat Exchanger Drum Pressure Vessel Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Pressure vessel Heat Exchanger Heat Exchanger Heat Exchanger Pressure Vessel Heat Exchanger Pressure Vessel Pressure Vessel Heat Exchanger Reactor ASME VIII Div.2 ASME VIII Div. 1 ASME VIII Div.1 - U AD-2000 ASME VIII Div. 1 ASME VIII Div.1 - U + ASME VIII Div.1 - U + ASME VIII Div.1 - U + ASME VIII Div.1 - U ASME VIII Div. 1 ASME VIII Div. 1 AD-2000 ASME VIII Div. 1 ASME VIII Div.1 - U + ASME VIII Div. 1 ASME VIII Div.1 - U ASME VIII Div.1 - U ASME VIII Div.2 ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div.2 4000x32420 3000x10260 4500/1600x26700 3200x31200 1400x5400 3300x10700 3200x50000 3000x10260 3200x31200 3400x17097 1532x8741 1920x10700 3600x12400 4500x22500 44.2 35 85 238 8.1 29.7 70 35 238 26.3 47 83 65 210 C.S. + SS 304L SA 387 Gr.11 cl.2 SA 387 Gr.11 cl.2 C.S. and Low Alloy C.S. SA 387 Gr.11 cl.2 and SA240 316 P275NL2 + 304L CLAD SA 387 Gr.11 cl.2 C.S. and Low Alloy P275NL2 + 316L CLAD C.S. and S.S. C.S. S.S. SA 537 cl.1 + Inconel 625 W. O. 33+3 39 53 20 31/31 39 11+3 39 20 11+3 81 60/70 30/13 63 + 4,5 1150x12500 8.8 SA 387 Gr.11 cl.2 21 3230x13550 1600/3100x6485 2750x17090 3400x15000 3200x17500 1575x5840 1420x9700 1670x15500 2398x15680 2433x17765 2399x16148 3950x32233 2530x18664 580x6888 1955x1634 2700x5890 2399x15993 650x2454 2600x11000 3000x18500 2300x28100 163 120 51 163 21 56.4 61.3 162 37 40 36 212 66 6.4 26 22 46 3.5 75 140 350 SA 299 + SS 316L W.O. C.S. and Low Alloy + SS SA 387 Gr.11 cl.2 15NiCuMoNb5-6-4 C.S. and S.S. C.S. and Low Alloy C.S. C.S. SA 387 Gr.11 cl.2 SA 387 Gr.11 cl.2 SA 387 Gr.11 cl.2 13Cr Mo 4-5 EN 10028-2 + WO SA 387 Gr.11 cl.2 C.S. SA 387 Gr.11 cl.2 S.S. SA 387 Gr.11 cl.2 C.S. C.S. SA 387 Gr.11 cl.2 SA 336 F11 Cl.2 + SA 387 Gr.22 110 + 7 W.O. 81 / 34 / 42 97 32 125 128 145 22 22 20 67+4,5 26/42 10 20/21 47 20/58 55 109/49 25 192 Column Reactor Column Stirene Heat Exchanger Steam Drum Reactors Columns Reactor Stirene Heat Exchanger Vessels Boiler Feed Water Preheater Heat Exchanger Vaccum Preconcentrator Glycol Separator Hydro-desulphurization reactor Teg - Contactor Heat Exchanger Plate Heat Exchanger Steam Drum Pressure Vessels BFW Pre-heater Cold exchanger Water Cooler Plate Heat Exchanger Plate Heat Exchanger Plate Heat Exchanger HDT Reactor Plate Heat Exchanger BFW Pre-heater Plate Heat Exchanger Pressure Vessels Plate Heat Exchanger Pressure Vessel Pressure Vessel Plate Heat Exchanger Ammonia Converter China, Sichuan - CCR 3094x18270 141 SA 387 Gr 11 cl.1 40 Plate Heat Exchanger Heat Exchanger ASME VIII Div. 1 2010 China, Sichuan - Tatoray 2031x15500 70 SA 387 Gr 11 cl.1 49 Plate Heat Exchanger Heat Exchanger ASME VIII Div. 1 Alfa Laval Packinox 2011 China - Great Orient 2003x14307 49 SA 387 Gr 11 cl.1 20 Heat Exchanger Heat Exchanger ASME VIII Div. 1 Alfa Laval Packinox 2011 China - Quanzhou 3920x19387 211 SA 387 Gr 11 cl.1 42 heat exchanger Heat Exchanger ASME VIII Div. 1 DFU DED NEN AEU REFERENCE LIST Job Client Year Country, Place - Plant Project ***** Some of Main equipments Manufactured By NuovaTUBITAL ***** Size Empty Material & Wall Thk. Service Dia. x Lenght Weight Shell / Head Type Applicable Code Ton. \ mm. \ 745x7300 108 S.S. 15 VFCR/Feed Exchangers Heat Exchanger AES ASME VIII Div.1 - U + TEMA R + API 660 1200 x 6100 30 C.S. and S.S. and low alloy 30 / 32 BFW Pre-heater Heat Exchanger BEU, BES, NFU, NEU, BES ASME VIII Div.1 - U + TEMA R + API 660 Russia, Angarsk 2163 x 14700 57 SA 387 Gr 11 cl.2 30/65/70 Heat Exchanger Heat Exchanger 2011 Kuwait - New booster station 3500x4000 29 C.S. 24/30 Pressure vessel + Heat Exchanger Pressure vessel + Heat Exchanger 2012 Turkey 3700x8980 27 Aluminum EN AW3003/5052 EN12392 50/50 Polymerization reactor Reactor AD 2000 2932x7252 52 SA 302 Gr.B 111/54 Steam Drum Drum ASME VIII Div. 2 - U2 2187 Koch Heat Transfer 2011 2174 Linde 2011 2193 Alfa Laval Packinox 2011 2195÷96 ISG 2200 Aksa Russia - Khabarovsk Refinery ASME VIII - 1 - Russian Regulation- GOST AE-NEL, BKU, BEM ASME VIII Div.1 - U + TEMA R + API 660 2206 Borsig 2012 Canada, Saskatchewan Belle Plain 2210 Bellelli Engineering 2011 Qatar, Halul Island - LPA Gas compressor 3452 x 219,1 0.8 C.S. 10/10 Electric Heaters & Filters Pressure vessel ASME VIII Div.1 - U 2212 Alfa Laval Packinox 2012 Russia - Tuapse 2580x16186 81 SA 387 Gr 11 cl.1 24/39 Heat Exchanger Heat Exchanger ASME VIII - 1 - Russian Regulation- GOST 2224 2225 2226 Alfa Laval Packinox Alfa Laval Packinox Alfa Laval Packinox 2012 2012 2012 Singapore, Jurong Island Singapore, Jurong Island Singapore, Jurong Island 3630x18946 2460x17065 2380x18922 80 35 66 SA 387 Gr 11 cl.1 SA 387 Gr 11 cl.1 SA 387 Gr 11 cl.1 28-40/56 21-28/27 40-53/86 2227 ENI 2012 Italy, Ferrara&Porto Torres 715x4356 3.8 C.S. 16 Heat Exchanger Heat Exchanger Heat Exchanger Pressure vessel + Heat Exchanger Heat Exchanger Heat Exchanger Heat Exchanger Pressure vessel + Heat Exchanger ASME VIII Div. 1 ASME VIII Div. 1 ASME VIII Div. 1 ISPESL - VSR, ASME VIII-1 + PED + ATEX 15/13 Pressure vessel + Heat Exchanger Pressure vessel + Heat Exchanger + Tube bundle ISPESL - VSR, ASME VIII-1 + PED + ATEX 2228 ENI 2012 2229 Bonatti-Irem-Gavazzi in progress Italy, Val d'Agri 3100x33640 122 2240 2241 2243 2244 2247 Alfa Laval Packinox Borsig UOP x Tecnicas Reunidas UOP x Tecnicas Reunidas FFC 2012 2012 2013 2013 2013 3480x19328 3082x16235 3966x30200 3974x24158 2500x8300 73 118 68 47 39 C.S.+ SCu6100 (AlBz8) W.D., Aluminum Bronze UNS S61400, F53 (Superduplex) + hastelloy C276 W.D. C.S., C.S.+ UNS S31254 (254SMO) clad, C.S.+SS316L CLAD SA 387 Gr 11 cl.1 15NiCuMoNb5-6-4 C.S. C.S. C.S.+ SS316L 2248 Alfa Laval Packinox 2013 4430x19280 52 SA 387 Gr11 cl.1 2249 Alfa Laval Packinox 2013 2252 Alfa Laval Packinox 2013 2253 SAIPEM 2013 2254 Minutes 2013 Italy, Venezia&SanNazzaro 2500x8280 China, Yangzi Indonesia Turkey, Izmit Turkey, Izmit Pachistan Korea, Ulsan Aromatics Complex Korea, Ulsan Aromatics Complex Russia Saudi Arabia, Jubai - Safco V - Urea Stand Alone Project Iraq, Baiji Refinery 13.3 42+3/45+3 Ammina & Glycol Adsorbers Column & Regenerators ASME VIII - 1 + PED 27-29/51 96/55 37/53 29/38 42,5+3 Heat Exchanger Steam Drum Adsorber + Drum Adsorber + Drum Urea Hydrolizer Heat Exchanger Drum Pressure vessel + Drum Pressure vessel + Drum Pressure vessel ASME VIII Div. 1 AD-2000 ASME VIII Div. 1 - U + PED ASME VIII Div. 1 - U + PED ASME VIII Div. 1 37.7/28 Heat Exchanger Heat Exchanger ASME VIII Div.1 4700x18450 103 SA 387 Gr11 cl.1 + cl.2 59.7/82 Heat Exchanger Heat Exchanger ASME VIII Div.1 2280x12330 57 SA 387 Gr22 cl.2 61/72.5 Heat Exchanger Heat Exchanger ASME VIII Div.1 3400x9830 31 SA 240 Ty304L/H+316H 15/12 Reactor Reactor ASME VIII Div.1 700x6000 5 C.S. Tube bundle Tube bundle ASME VII Div.1 REFERENCE LIST Job Client Year Country, Place - Plant Project ***** Some of Main equipments Manufactured By NuovaTUBITAL ***** Size Empty Material & Wall Thk. Service Dia. x Lenght Weight Shell / Head 2255 Alfa Laval Packinox 2013 2257 Selas-Linde 2013 2258 ENI 2013 2259 2260 2266 2268 2269 2270 2271 2272 2274 2277 2280 2281 2282 Foster Weeler Italia Alfa Laval Olmi Alfa Laval Packinox UOP USA Alfa Laval Packinox Alfa Laval Packinox Alfa Laval Packinox Borsig UOP UOP SAIPEM Alfa Laval Packinox Borsig 2013 2013 in progress in progress in progress in progress in progress in progress in progress in progress in progress in progress in progress Applicable Code Ton. \ mm. \ New Zeland, Temahi Hou Refining Turkey, Izmit Italy, Ravenna - Eni Versalis Russia, Salavat USA Taiwan, Taipei Iraq, Bagdad India, Reliance India, Reliance India, Reliance South Korea Russia, Volgograd KSA, Dubai Nigeria, Dangote Type 2073x15008 54 SA 387 Gr11 cl.1 45/68 Heat Exchanger Heat Exchanger ASME VII Div.1 3210x9600 52 SA 387 Gr22 cl.2 + Gr91 52/51 Prereformer Prereformer ASME VII Div.2 + B31.3 Tube bundle Tube bundle ASME VII Div.1 + TEMA R Reformer Heat Exchanger Feed Vaporizer Heat Exchanger Adsorber + Drum Heat Exchanger Heat Exchanger Heat Exchanger Channel Adsorber + Drum Adsorber + Drum HP Pressure Vessel Heat Exchanger Channel Reformer Heat Exchanger Heat Exchanger Heat Exchanger Pressure vessel + Drum Heat Exchanger Heat Exchanger Heat Exchanger Channel Pressure vessel + Drum Pressure vessel + Drum Pressure vessel Heat Exchanger Channel ASME VII Div.1 + TEMA R ASME VII Div.1 + TEMA B ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.1 ASME VII Div.2 ASME VII Div.1 AD-2000 1000x6400 5 C.S. 1910x11000 3710x23500 2660x19570 2120X7700 5160x25500 5160x25500 3420x21000 2850x8500 3824x14600 2380x3600 35 200 43 7.5 190 190 115 60 14 34 SA 387 Gr11 cl.2 + C.S. C.S. SA 387 Gr11 cl.1 C.S. SA 387 Gr11 cl.2 SA 387 Gr11 cl.2 SA 387 Gr11 cl.2 SA 387 Gr11 cl.2 C.S. C.S. C.S. 35/20 29/21 32/24 16/19 57/59.9 57/59.9 56/71.3 95 31/47 80/94 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 886 – Year 1991 Scrubber I.D. 7000 mm; Thickness from 6 to 12 mm Material (Materiale): Stainless Steel Code (Codice) : ASME VIII Div. 1 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1205 – Year 1994 Gas recuperator (Tube to Tubesheet GTAW Automatic) Ø 3200 mm; Thickness; 25 mm Material (Materiale): A 387 Gr.11 Cl2 – A 204 Gr. B Code (Codice) : ASME VIII Div. 1 + ISPESL _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 1500 – Year 1998 Basket ammonia converter internals for reactor I.D. 3000 mm; Thickness From 30 to 60 mm Material (Materiale) : ASTM A240 Tp. 321 – Inconel 600 Code (Codice) : ASME VIII Div. 1 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1594 – Year 1999 Alluminium Reactors (Reattori in alluminio) I.D. 3200 mm; Length; 9200 mm Material (Materiale): Alloy 3003 / 5052 Code (Codice) : VSR + AD MERKBLATTER _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1604 – Year 1998 N°2 Skid for CO2 removal plant Code (Codice) : ASME VIII Div. 1 + ISPESL _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1811 – Year 2002 N°1 Multichamber Reactor (Reattore Multicamera) I.D. From 1300 to 2600 mm; Lg. 45000 mm; Thickness from 34 to 55 mm Material (Materiale) : ASME SA 387 Gr.11 Cl.1 Weight (Peso): 201.600 Kg Code (Codice) : ASME “U” STAMP-ASME VIII Div. 1 Ed.’98 + Add. ‘00 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1846 – Year 2002 Cover for Cruiser Ship (Coperture per navi) Width 6650 mm; Lg. 22000 mm ; Thickness from 5 to 20 mm Material (Materiale) : ALUMINIUM LEGA 5083 Weight (Peso) : 18524 Kg LLOYD’S REGISTER INSPECTION _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1867/1 – Year 2003 N°4 DEGASSING DRUM (Serbatoio di degasazione) I.D. 2468 mm; Lg. 14550 mm; Thickness from 47 to 66 mm Material (Materiale) : Diross 500 S (made by Dillinger) Weight (Peso): 65.000 Kg Code (Codice) : AD 2000 Merkblatter - PED (DIR. 97/23/CE) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1890/1 – Year 2003 FRACTIONATOR (UNITA THERMAL CRACKING) I.D. 2502 mm; Lg. 44100 mm; Thickness from 25 To 14 mm Material (Materiale) : P275 NH Weight (Peso): 54.000 Kg Code (Codice) : ISPESL – VSR REV.95 / ED.99 + PED _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1894/7 – Year 2003 Exchanger (Scambiatore) I.D. 1100 mm; Lg. 7650 mm; Thickness from 13 mm Material (Materiale) : Channel + shell P275 NH Tubesheet A 266 Gr.2 Tube bundle A 210 Gr.A1 Øe 19.05 mm Weight (Peso): 12.000 Kg Tube bundle 8500 Kg Code (Codice) : PED (DIR. 97/23/CE) – Racc. VSR Rev. 1995 Ed 1999 – Tema ‘R’ _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1907 – Year 2003 N°4 Storage vessel (Serbatoio stoccaggio GPL) I.D. 4200 mm; Thickness From 12.5 to 21 mm Materiale (Material) : P 355 NL2 Code (Codice) : ISPESL VSR Rev. 95 / Ed. 99 + PED ( Dir. 97/23/CE ) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 1921 – Year 2004 N°1 Plymerization Reactor I.D. 2790 mm; Lg. 6538 mm Thickness shell; 45 mm Material (Materiale) : ASTM B 209 ALLOY 5052 Weight (Peso): 14.000 Kg Code (Codice) : ISPESL - VSR ASME VIII Div. I _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1924 – Year 2004 N°1 Urea Hydrolizer I.D. 2500 mm; Thickness 42 + 5 mm Material (Materiale) : ASTM A516 Gr.70 + 316 L (overlay) Code (Codice) : ASME VIII Div. 1 2001 ED.2001 + ADD. 2003 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1925 – Year 2004 N°1 Column (Colonna di Preflash) I.D. From 1794 to 4500 mm; Lg. 26.200 mm; Thickness from 10 to 20 mm and 10+3 mm clad plate Material (Materiale) : ASTM A516 Gr.60 and A516 Gr.60 + A240 316L Weight (Peso): 45.500 Kg Code (Codice) : ISPESL – VSR – PED/CE (DIR. 97/23/CE) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ______________________________________________________________________________________________________________ __________________________________________________________________________ Job 1929/4 – Year 2004 N°1 Systeme and Vaporization I.D. 1500 mm; Lg. 5030 x 4614 mm; Thickness shell; 5 mm Fluid type: Cryogenic Liquide Design temperature: -196 / +120 °C Material (Materiale) : ASTM A240 304L Weight (Peso): 3550 Kg Code (Codice) : ASME VIII Div. I Test. PED/CE (DIR. 97/23/CE) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2021/1 – Year 2008 N°1 FRACTIONATOR COLUMN I.D. 1800 & 3100 mm; Thickness 11+3 mm Weight : 65 t Total Lenght: 50100 mm Material : P275 NL2 + Clad X2 Cr Ni 19-11 Code : EN 13445 – PED / ATEX _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2041 – Year 2008 N°3 INTERSTAGE COOLERS I.D. 1800 mm; Thickness 60 & 70 mm Weight : 83 t Total Lenght: 10700 mm Material : SA 516 Gr. 70 Code : ASME VIII Div. 1 Ed. 2004 Add. 2005 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2053 – Year 2008 VACUUM PRECONCENTRATOR/SEPARATOR Materiale (Material) : ASME SA 240 Gr 316L Code (Codice) : ASME VIII Div. 1 ED.2004 + ADD. 2006 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) / P.O. Box 232 Marghera-centro, VE (Italy) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2055 – Year 2008 GLYCOL SEPARATOR I.D. 4500 mm; Thickness 63 + 4.5 mm Weight : 213 t Material : ASME SA 537 Cl.1 (+ weld overlay INCONEL 625) Code : ASME VIII Div. 1 ED.2004 + ADD. 2006 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2070 – Year 2009 MAIN COLUMN I.D. 6500 mm; Thickness 39 + 3 mm (bottom section ) Total Weight : 311 t Total Lenght : 48950 mm Material : ASME SA 387 Gr. 12 Cl 2 + cladding Type 410S Code : ASME VIII Div. 1 ED.2004 + ADD. 2006 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2079 – Year 2009 STEAM DRUM I.D. 3200 mm; Thickness 97 mm Weight : 163 t Total Lenght: 18900 mm Material : 15 NiCuMoNb 5-6-4 Code : PED 97/23/CE AD2000 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2082/5 – Year 2009 HORIZONTAL COLD SEPARATOR I.D. 2400 mm; Thickness 48 mm Weight : 68 t Total Lenght : 19604 mm Material : ASME SA 516 Gr 60 (HIC) Code : ASME VIII Div. 1 ED.2004 + ADD. 2006 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _______________________________________________________________________________________________________________ _______________________________________________________________________________________________________________ Job 2153 – Year 2010 N°3 FEED GAS EXPANDER INLET KO DRUM I.D. 2600 mm; Thickness 109 mm Weight : 75 t Total Lenght: 11000 mm Material : SA 537 Cl. 2 Code : ASME VIII Div. 1 Ed. 2007 Add. 2008 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants _____________________________________________________________________________________________________________ Job 2155 – Year 2010 N°1 AMMONIA CONVERTER I.D. 2300 mm; Thickness 192 mm Weight : 350 t Total Lenght: 28100 mm Material : SA 336 F11 Cl. 3 & SA 387 Gr.22 Cl. 2 Code : ASME VIII Div. 2 Ed. 2007 Add. 2008 + PED 97/23/CE _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera - VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Ph. (+ 39) 041 25870 11 / fx. (+ 39) 041 25870 40 C.F. e V.A.T.: T01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2158 – Year 2010 N°1 PRESSURE VESSEL I.D. 3094 mm; Thickness 25 & 40 mm Weight : 141 t Total Lenght: 18500 mm Material : SA 387 Gr.11 Cl.2 + Internal Bundle in 321 Code : ASME VIII Div. 1 Ed. 2007 Add. 09 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 REA n. 165143 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2241 – Year 2012 N°1 STEAM DRUM I.D. 3082 mm; Thickness 96 mm (shell) & 55 mm (heads A.F.) Net Weight (empty): 120 t Total Length: 16235 mm Material : 15NiCuMoNb5-6-4 Code : AD-2000 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2243/1 – Year 2012 / 2013 N°14 PSA ADSORBERS I.D. 3200 mm; Thickness 37 mm (shell) & 53 mm (heads A.F.) Net Weight (empty): 41 t Total Length: 10300 mm Material : SA 516 Gr. 70 certif. EN10204-3.2 Code : ASME VIII Div. 1 Ed. 2010 Add. 11 (U-Stamped) + PED (CE marked) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2243/1 – Year 2012 / 2013 N°14 PSA ADSORBERS I.D. 3200 mm; Thickness 37 mm (shell) & 53 mm (heads A.F.) Net Weight (empty): 41 t Total Length: 10300 mm Material : SA 516 Gr. 70 certif. EN10204-3.2 Code : ASME VIII Div. 1 Ed. 2010 Add. 11 (U-Stamped) + PED (CE marked) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2244/2 – Year 2013 N°1 TAIL GAS DRUM I.D. 3974 mm; Thickness 13 mm (shell) & 13 mm (heads A.F.) Net Weight (empty): 47 t Total Length: 24200 mm Material : SA 516 Gr. 70 certif. EN10204-3.1 Code : ASME VIII Div. 1 Ed. 2010 Add. 11 (U-Stamped) + PED (CE marked) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2253 – Year 2013 N°2 REACTORS I.D. 3400mm; Thickness 15 mm (shell) & 12 mm (heads A.F.) Net Weight (empty): 31 t Total Length: 9830 mm Material : SA 240 Ty304L-304H+ SA 240 Ty316H Code : ASME VII Div.1 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2259 – Year 2013 N°1 REFORMER HEAT EXCHANGER I.D. 1910 mm; Thickness 35 mm (shell) & 20 mm (heads A.F.) Net Weight (empty): 35 t Total Length: 12000 mm Material : SA 387 Gr.11 cl.2 + SA 516 Gr. 70 certif. EN10204-3.1 Code : ASME VIII Div. 1 Ed. 2010 Add. 11 ( Russian Technical Passport ) _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276 nuova tubital ASME STAMPS ISO 9001 ISO 14001 OHSAS 18001 CHINA LICENSE Società Cooperativa per Azioni Design - manufacturing - mechanical component - Oil Refinery - Chemical Gas - Petrochemical Plants ____________________________________________________________________________________________________________ ______________________________________________________________________________________________________________ Job 2260 – Year 2013 N°1 FEED VAPORIZED I.D. 3710 mm; Thickness 29 mm (shell) & 21 mm (heads A.F.) Net Weight (empty): 200 t Total Length: 23500 mm Material : SA 516 Gr. 70 certif. EN10204-3.1 Code : ASME VIII Div. 1 Ed. 2010 Add. 11 _______________________________________________________________________________________________________________ Via delle Querce, 45 – 30175 Marghera – VENICE (ITALY) Web: www.nuovatubital.it e.mail: mail@nuovatubital.it Cooperative register inscription number: A137468 Ph (+39) 041 25870 11 / Fx. (+39) 041 25870 40 Capitale sociale € 408.066,00 i.v. Reg. Imprese di Venezia, C.F. e V.A.T. : IT01491010276