Nebec Poster Draft 4

advertisement

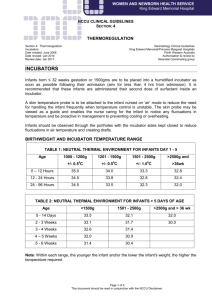

Transportable Infant Incubator for Developing Countries R. Cichocki, A. Midouin, and R. O’Laughlin; Advisor: B.F. BuSha Department of Biomedical Engineering, The College of New Jersey, Ewing, NJ Structural Design Abstract Power consumption by the electronics will be negligible compared to the expected 200W max from the heating element. The power consumption of the electronics is 340 mW to 610 mW. Prototype testing was performed using an acrylic case, fans, vents, a 12 V 35 Ahr battery, and four headlights. The results are seen below. The estimated time for the battery to reach 11V while operating is 100 minutes. The incubator target temperature was reached at 7 minutes. • The frame of the incubator is composed of two sections, which includes the casing surrounding the heating mechanism and its controls and the upper portion that will contain the infant. • The lower frame is comprised of aluminum 3003 plates. The upper frame is a transparent polycarbonate casing. • The incubator is assembled with corner blocks, base blocks, and machine screws. 12.8 Fig. 2: Structural design of incubator (in progress). Design of Temperature Pulse Width Modulation Controller Control System 11.8 11.6 11.4 11.2 11 555D C4 .22u 5VSource C3 .01u 8 VCC 8 5 OS2 V+ 2 4 5 6 7 2k C2 .1u TRIGGER RESET OUTPUT CONTROL THRESHOLD DISCHARGE R19 3 0 0 2.5V_VirtGround Battery 0 12VBattery R11 AC = TRAN = DC = 12 Dif f Amp 6 5 OS1 LM741 OUT OS2 + U3 R9 2 R5 2 5VSource 5k U2 LM7805C OUT C5 .1u 1k R10 3 IN 3 1 V- 4 0 GND 5VSource 5k R6 5k 1 12VBattery C6 .32u 0 5VSource 1k 0 R8 2k R12 5VSource 5k 4 R7 2k 1 6 2.5V_VirtGround 5 V- OS1 LM741 OUT OS2 7 + V+U5 2 R29 2k 3 R30 2k 5VSource 2.5V_VirtGround Power Supply 0 Sensor & Amplifier D3 D5 D1N4001 D1N4001 5VSource Dif f Amp R18 10K SET = 0.55 U4A3 V+ 9 + OUT 4 R13 1k - 12 LM339 OUT 8 R25 2k - 12 LM339 R27 1k D2 5 U1A3 4 - 12 U7D3 V+ R1 1k 11 5VSource U6D3 V+ + 2 OUT 10 V- - 12 LM339 LM339 13 V- 0 13 R28 D6 5VSource 2k - 12 D1N4001 V- 0 Temperature & Battery Warning R26 2k 0 12VBattery D4 D9 D1N4001 D1N4001 5VSource R21 20K SET = 0.775 R24 10k 5 U6A3 V+ R2 1k 7 + OUT - 12 LM339 D7 D1N4729 0 5VSource U6B3 V+ + 2 OUT 4 1 6 - 12 LM339 V- 30.0 25.0 20.0 15.0 10.0 5.0 2 4 6 8 10 12 14 V+ + OUT 10 + OUT Dif f Amp D1N4001 35.0 Time (min) 5VSource 0 D8 D1N4001 40.0 0 V- 5VSource R17 10K SET = 0.45 45.0 14 11 0 14 0.0 5VSource U6C3 V+ + 2 V- 12 5VSource 5VSource 5 10 50.0 555D Control 8 Prototype Temperatures M1 IRLZ34N 1k Temperature (Celsius) + 7 U8 Control R4 3 6 Time (min) X1 GND 3 6 R15 2k TRIGGER RESET OUTPUT CONTROL THRESHOLD DISCHARGE 4 1 62k 1 GND Dif f Amp VOS1 LM741 OUT 2 RLoad 10 R3 25k X2 VCC 2 4 5 6 7 4 2 LM339 • The controller will regulate heating element power by pulse width modulation (PWM) created using two 555 timing chips. This will reduce power loss by the transistor. 12 0 R14 62k 2.5V_VirtGround • The output of the measurement circuit will be an input to the controller, which will be physically realized with one operational amplifier, as described in [6]. Currently only shown as an integrator. 12.2 47u 7 • A buzzer and LED will warn when the temperature is out of range or the battery charge is low. 12.4 5VSource R31 • The measurement circuit will monitor air/skin temperature and the voltage of the 12 V battery. This circuit will be used to verify if the temperature is within 33.5 2oC, a range derived from E. N. Hey [5]. 12.6 12VBattery C1 V+ An incubator is a medical device which can maintain and regulate an appropriate environment for infants. This is a crucial device for preterm infants, which are infants born before 37 weeks of gestation [1]. Their low birth weight and under developed organs make them very sensitive to environmental humidity, temperature, and infection. Preterm birth rates range from 5% in developed countries to 25% in developing countries [2]. Furthermore, most births in developing countries do not occur in a hospital. The World Health Organization and Engineering World Health stress these facts and the need for a transportable infant incubator designed for use in developing countries. The incubator needs to be robust to withstand travel through difficult conditions and cost effective since it will be used in low resource areas [3]. Parts need to be inexpensive and easily replaced in developing countries. Previous incubators were researched and the proposed project draws from the work of the Car Parts Incubator and Engineering World Health [1,4]. Battery Voltage (V) • The ventilation system, located within the lower frame, consists of aluminum vents, halogen headlight bulbs, computer fans, and a humidifier. 0 Introduction Battery Voltage 13 1 Premature infants make up 25% of all births in developing countries and are usually born outside of a hospital. The World Health Organization and Engineering World Health have stressed the need for a transportable infant incubator designed for use in developing countries. The goal of this project is to create a device which protects and incubates an infant while being transported to a hospital. The device needs to be economical, robust, and use easily replaceable parts. The heating mechanism will use computer fans, a humidifier, and car headlights to provide heat. The temperature will be automatically maintained by a proportional integrative derivative (PID) controller. Large temperature deviations and low battery charge will be announced through an audible alert. The base will be made of aluminum due to its low cost and durability. The bassinet cover will be polycarbonate due to its low thermal conductivity and strength. A theoretical MATLAB model of the preterm infant and incubator will be implemented to evaluate the performance of the design. Testing goals will include finding average power consumption, times to reach target temperature (33.5oC), and the safety of the device. Results V- 0 0 Fig. 3: Schematic of current electrical design. Testing • Testing and verification will employ a MATLAB model of an incubator to simulate its function and provide data for comparing measured values. To construct a theoretical model, the compartmental model previously developed by Simon and Reddy [7] and Yassel [8] will be used. • A verification device that models the volume, surface area, and approximate shape of an infant will be utilized to predict the heat conduction within the incubator. This device will be made of low-density polyethylene to approximate the thermal conductivity of an infant’s skin and contain fluids heated by a submersible heater to mimic metabolic heat [9]. Fig. 5: (Top) change in battery voltage over time. (Bottom) measured temperature at the middle of the incubator and at the inlet. The red squares are the inlet temperature and the blue diamonds are the temperature in the center of the prototype. Conclusions Prototype testing shows that the design can heat the system beyond requirements in a room temperature environment. Future work will include finishing structural/ventilation construction, integrating the electronics with the structure, testing in different temperature environments, and tuning the system to specifications. The presented design can be adjusted to satisfy local manufacturing capabilities. The design can be further developed by including a breathing monitor, oxygen control, and humidity sensor. References Fig. 1: Functionality and cost relationship of proposed design and other designs. Fig. 4: MATLAB model of incubator and control system. Will be used for testing and verification. [1] Engineering World Health. (2010, December). Engineering World Health: Projects that Matter [Online]. Available: http://ewh.org/index.php/programs/technology/design/ [2] P. Steer , “The epidemiology of preterm labour,” BJOG-Int. J. Obstet. Gy., vol. 112, issue. s1, pp. 1–3. Feb. 2005, doi: 10.1111/j.1471-0528.2005.00575.x [3] World Health Organization. Medical Devices: Managing the Mismatch. [Online]. Available: http://www.who.int/medical_devices/access/en/ [4] Design that Matters. (2011, November 29) NeoNuture: the "Car Parts" Incuabator.[Online].Available: http://designthatmatters.org/portfolio/projects/incubator/ [5] E. N. Hey, and G. Katz, “The optimum thermal environment for naked babies.” Arch. Dis. Child., 1970, vol. 45, no. 241, pp. 328-334, June 1970. doi:10.1136/adc.45.241.328 [6] V. Michal, C. Prémont, G., Pillonet, and N. Abouchi, "Single active element PID controllers," Radioelektronika (RADIOELEKTRONIKA), 2010 20th International Conference , vol., no., pp.1-4, 1921 April 2010 [7] B. Simon, and N. Reddy. "A theoretical model of infant dynamics." J Biomech Eng-T ASME, vol. 116, pp. 263-269, August 1994 [8] A.T. Yassel. “A simulation model of infant - incubator - feedback system with humidification and temperature control,” unpublished. [9] K. Holmes. "Thermal conductivity data for specific tissues and organs for humans and other mammalian species." Thermal Properties. 1990