10684InternationalPaintLtd

International Paint Ltd.

Oil & Gas Solutions

Agenda (2.5 hours)

1.

International Paint Product Range

2.

Structural Steel

3.

Corrosion Under Insulation (CUI)

4.

Tank Linings

5.

Concrete

6.

Pipelines

7.

Passive Fire Protection (PFP)

8.

Summary

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

International Paint

The Oil & Gas Partner of Choice

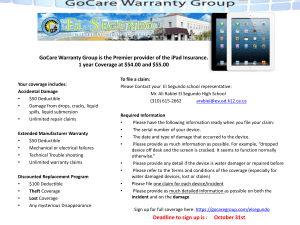

International Paint supply all the major multinationals in the Oil & Gas

Industry.

International Paint are named on the Shell, Exxon, Chevron, Saudi

Aramco, Dow, Vopak global specifications to name but a few.

We work closely with the owners to provide technical support and ensure our products meet their needs through test work.

Our support ensures that the owners see the true value of using

International Paint products.

On-site we can provide technical consultation on choice of paint for difficult maintenance jobs as well as Technical Support Representatives to attend application of the paint and train the applicator.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

International Paint –

Supplying all your paint needs

High Temperature

Surfaces

Corrosion

Under

Insulation

Structural

Steel

Tank

Internals

Tank

Externals

Concrete

Fire

Protection

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

OEM

International Paint - Technology Leader

International Paint have various systems which utilise market leading technology to provide solutions to your most difficult corrosion issues:

Intertherm 751 CSA – unique, patented heat & corrosion resistance

Enviroline – High performance, thick film, rapid cure tank linings

Ceilcote – Resistant to the most highly aggressive chemical attack

Intercrete – Cementitious repair mortars and linings

Chartek – 100% volume solids passive fire protection

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Structural Steel

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Typical Paint Specification for

UnInsulated External Surfaces <120˚C

Polyurethane Topcoat – 50µm

Epoxy Intermediate – 100µm

Zinc Rich Primer – 50µm

Steel Substrate

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Zinc silicate technology

Rapid overcoating – within 4½ hours

Available with various zinc levels to fulfil International Standards requirements

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Zinc primers

Often, specifications for zinc primers will be guided by the following industry standards, which set levels of zinc dust in the dried film:

Standard

SSPC Paint 20

Standard

NORSOK M501

ISO 12944

Zinc Level

Level 1 ≥85%

Level 2 ≥77% <85%

Level 3 ≥65% <77%

≥80%

≥80%

ASTM D520 – zinc dust should contain >94% zinc metal

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Micaceous Iron Oxide - MIO

MIO is a lamella type (flake like) form of iron oxide which is insoluble in water, organic solvents and alkalis

When incorporated into the coating dry film, its lamella type shape aligns itself parallel to the substrate providing a barrier of overlapping flakes

This barrier prevents the ingress of water, oxygen and ions and thus seriously slows down the corrosion of steel

MIO flakes

Steel Substrate

MIO Flakes

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Barrier Pigments – MIO - micaceous iron oxide

Pigment

Conventional “spherical” STEEL SUBSTRATE

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Barrier Pigmentation

Role of a Top / Finish Coat

A high quality finish and vibrant colours are important for any structure

.

The main function of finishes is to resist the damaging effects of the sun which is normally interpreted in coatings as ultraviolet (UV) resistance as well corrosion protection.

UV resistance is the ability of a finish coat to maintain its colour and gloss level over an extended period of time

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Durability of Finishes

The Carbon-Carbon (C-C) bonds within traditional “organic” coatings are less resilient than those found in acrylic polysiloxanes

Polysiloxane coatings are significantly more resilient to UV (sunlight) degradation which means much improved cosmetic properties over time in service

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Gloss Retention Over Time - UV A

100

80

60

40

POLYSILOXANE

POLYURETHANE

20

EPOXY

EPOXY - ACRYLIC

0

0 500 1000 1500

Time (hrs)

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2000

ALKYD

2500 3000

Colour Stability – External Exposure

3

2.5

2

1.5

1

0.5

0

0 2 4 6

Months

8 10 12 14

Epoxy Polysiloxane

Acrylate Polysiloxane

Polyurethane

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Air separation unit - Germany

New steelwork required a durable, corrosion resistant paint system to protect the steel and keep it looking good for many years.

A 3 coat zinc based system was chosen from International Paint.

The Interzinc 22 primer and Intergard

475HS intermediate give long-term corrosion resistance and the

Interthane 990 topcoat provides a long-term cosmetically good finish.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Refinery vessel externals

Un-insulated vessel externals coated with Interseal 670 and

Interthane 990

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Maintenance of Tank Externals

In order to reduce the amount of dust created the previous coating on these tanks was removed by hydro blasting.

Surface tolerant Interplus 356 was used to prime the hydro blasted steel followed by epoxy intermediate

Interseal 670HS and a top coat of

Interthane 990.

The system was roller applied and cured at 0 °C allowing application during the winter with no additional heating.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Long lasting finish

Vessels at a gas processing plant in the Netherlands coated with Interfine 878

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2009 – Condensate Separator Container

(PEMEX, Mexico)

“Power Tool Cleaning” (SSPC- P3)

Condensate Separator Vessel

Interzone 954 was applied while the condenser was operating and damp

The product had a hard drying time of 8 hours

There was no problem with runoff or condensation on the surface

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2009 – Condensate Separator Container

(PEMEX, Mexico)

Application of Interzone 954

Application of Interzone 954 on 6” condensate pipe

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2007 – Ettrick Sage Hot Tap Project

(ExxonMobil, UK)

Hot tap structure (500 ltrs )

- Surface prep: blast Sa2.5 or SSPC-SP6

- Full coat Interzone 954 (450

m)

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2003 – Valves

(PEMEX, Mexico) (cont.)

Manually cleaned and washed with fresh water

Two coats of Interzone

954 applied with conventional spray equipment and a brush

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

2003 – Valves

(PEMEX, Mexico) (cont.)

Application of Interzone 954 grey

Final appearance of

Interzone 954 yellow

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

High Temperature

Coatings

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

High Heat

Certain epoxy-phenolic binder systems are suitable for high temperatures up to the 230 °C (446°F) limit, thereafter, alternative ‘inorganic’ binder systems need to be used

Product Name

Intertherm 715*

Intertherm 228

Intertherm 875*

Intertherm 751 CSA

Resin Type

Modified Silicone

Epoxy Phenolic

Silicone-acrylic

Titanium Modified

Inorganic Co-Polymer

Silicone

Maximum

Temperature

<100 ° C

230 ° C

260 ° C

400 ° C

Intertherm 50* 540 ° C

*For some of these materials where improved corrosion protection is required, the Intertherm products can be applied directly over zinc rich primers (e.g. Interzinc 22)

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Durable finish for chimney stacks

New chimney stack operating at this refinery required a high temperature resistant finish.

Interzinc 22 was applied to the grit blasted surface in the workshop and once installed on site Intertherm

50, aluminium silicone was applied.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Corrosion Under

Insulation

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Inorganic Zinc Silicate Coatings

Many engineers strictly follow the NACE

RP0198 recommendations, & use IOZ for all high temperature service above 120 °C.

BUT … NACE do not recommend the use of Zinc Silicates (or Galvanising) on Carbon

Steel under warm, wet Insulation.

CUI with IOZ Primer

“.… Inorganic Zinc Coatings or Galvanising shall not be used under

Thermal Insulation in the 50-150 °C service temperature range for long term or cyclic service. Zinc provides inadequate resistance in closed, sometimes wet environments.… ”

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intertherm 50 – Cyclic heating to 400°C

After heating to 3x400 °C

Followed by

12 months

C5M

Visually the coating was in good condition

Rust Ri 5

Cracking Density 5;

Size 3-5

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Gas Processing Plant, Austria

Gas processing plant in Austria.

The gas driers are filled with

SilicaGel to absorb moisture from the gas.

Equipment cycles from ambient up to over 300 ˚C in order to drive moisture out of SilicaGel once it is saturated.

Previous zinc silicate and aluminium silicone system had failed.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

31

CUI Coating Selection

Coating to prevent CUI

New Construction Maintenance

0-200 °C 0-400 ºC 0-100 °C

Blast Sa2

½

Intertherm 228

2 x 100

μm

Blast Sa2 ½

Intertherm 751

CSA

1 x 175 μm

St2/St3

Interseal

670HS

2 x 100 μm

0-150 °C 0-200 °C 0-400 ºC

St2/St3

Interplus 256

2 x 80 μm

SA 2.5

Intertherm

228

2 x 100

μm

SP11 / SA 2.5

Intertherm

751 CSA

2 x 100

μm

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Interplus 256 – Preventing CUI

Stripper columns were coated with

Interplus 256 (aluminium) whilst in service.

The surface temperature was 56 °C and 3 coats of Interplus 256 were applied in quick succession to create a total dry film thickness of 150-

200µm.

After the coating had cured the insulation was replaced on the stripper columns

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intertherm 228 – Case History

Intertherm 228 was applied to the outside of this insulated vessel.

The vessel had been suffering from Corrosion Under

Insulation (CUI)

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intertherm 751 - Product Properties

Two component

Ambient cure

High build 1x200 μm or

2x125 μm

High temperature corrosion resistant coating 400 ºC

Resistant to temperature cycling

Based on Titanium Modified

Inorganic Copolymer

Technology

Pigmented with Aluminium

Flake

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Temperature Cycle – Ambient to 300°C

Preparation - Garnet Blast Sa2

Roller Application – 2 Coats

No Insulation

Aluminium Jacket with Perforations for Protection

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Cyclic Pipeline in C5M

Environment

Photographs from 1 st inspection after 11 months.

Inspected again after 28 months and was still in good condition.

Following successful trial customer has specified Intertherm

751 CSA for all vessels and pipeline under insulation

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Propane Treater Unit - Australia

260

80

40

Time

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Propane Treater Unit, Australia

Application October 2005.

Grit blast 2.5.

Airless Spray Applied.

1x200µm.

Total Area 200m².

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Propane Treater Unit, Australia

Photographs during inspection after one year in service. Also passed second inspection in

October 2007.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Propane Treater Unit, Australia

Further inspections have shown 7 years service with no signs of degradation

2008

2011

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Linings

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

International Paint Linings Offer

International Paint have the largest linings range in the market

International paint linings can be use to protect the storage tanks, process vessels, equipment, pipe lines and secondary containment areas.

International Paint linings can protect both steel and concrete substrates from attack by a wide range of aggressive chemicals.

The International Paint Linings Offer includes epoxy, epoxy phenolic, epoxy novolac, vinyl ester, novolac vinyl ester, polyurethane and polyurea/polyurethane hybrid technology.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

44

Interline

Interline is International Paint’s core linings offer

In the market since 1970s

Mostly epoxy based linings for general internal tank lining use

Widely specified by Oil & Gas Majors and global chemical producers

Range has numerous owner approvals and long track record of success.

Normally used to protect steel storage tanks

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

45

Interline Product Highlights

Interline 850

Cost effective, new construction epoxy tank lining. Thin film to offer the lowest cost per square meter in terms of material cost.

Interline 984

Multi-purpose epoxy phenolic tank lining. Resistant up to 90 °C in constant immersion. Suitable for immersion in hydrocarbons including biofuels. One of the few tank linings approved to EI 1541 making it suitable for EI/JIG Standard 1530 compliant jet fuel storage systems

Interline 984 Matcote

Chopped strand reinforced lining system applied by automatic chopper gun and spray equipment. Applies reinforced lining system at faster rates than conventional hand lay systems.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

46

Interline Examples

Diesel storage tank in South Africa.

Lined with Interline 984

Brine tank in Malaysia.

Internally lined with Interline 399

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Jet Fuel Tank in Turkey.

Lined with Interline 850

47

Ceilcote

Ceilcote Company founded in 1926

Acquired by International Paint in 2006

Specialists in vinyl ester and novolac vinyl ester resins which can resist the most aggressive chemical environments

Leaders in the protection of Flue Gas De-Sulphurisation plants

Usually used to protect steel and concrete chemical storage tanks and secondary containment areas.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

48

Ceilcote Product Highlights

Ceilcote Mat Screed Systems

Highly reinforced systems to give high strength and chemical resistance. These hand applied systems give long term chemical resistance, ideal for concrete tanks and secondary containment areas.

Ceilcote CeilLine Systems

The flexible base layer in the CeilLine systems give crack bridging properties which means that if the concrete moves and cracks after application of the system the topcoat will remain intact and not crack.

Ceilcote 282HB

Widely specified in Flue Gas De-Sulphurisation equipment – Ceilcote

282 has excellent high temperature resistance and this high build version can be applied to the correct thickness in 2 coats instead of 3.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

49

Ceilcote Examples

Secondary Containment Area in Turkey.

Lined with Ceilcote 232 Mat Screed

Flue Gas De-Sulphurisation Unit in Austria

Lined with Ceilcote 282

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Crystallisers in Jordan.

Internally lined with Ceilcote 180

50

Enviroline

Enviroline Company founded in 1960

Acquired by International Paint in 2008

Specialists in high temperature resistant epoxy novolac linings

Enviroline products offer cost reduction to the asset owner due to quick return to service times and winter cure grades

Specified by many Oil & Gas Majors

Usually used to protect steel storage tanks and process vessels

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

51

Enviroline Product Highlights

Enviroline 376F-60

Flake and fibre reinforced spray applied in one thick coat of 1500µm.

Does not required any other layers or rollering as traditional reinforced system do.

Full cure in 14 hours at 25 °C

Enviroline 376F LT Series

Low Temperature cure grade. Cures down to -7 °C. Cure in 3 days at

0 °C. Traditional epoxy linings do not cure below 5°C and are not recommended to cure below 10 °C.

Enviroline 405HT

High temperature immersion resistant thick film lining. Can resist up to

120 °C in constant immersion. Applied in one thick coat of 500µm. Full cure in 14 hours at 25 °C.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

52

Enviroline Examples

Buried pipeline in USA.

Externally lined with Enviroline 376F-30

Buried Fuel Tank in USA.

Lined with Enviroline

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

High temperature process vessel in Italy.

Internally lined with Enviroline 405HT

53

Storage Tank Base

Chemical storage tank in the UK required sealing of the gap between tank and tank base.

Intercrete products are used with an elastic reinforcement tape to seal the gap between the tank and the tank base.

The Intercrete system is has good adhesion to both concrete and steel to prevent water entering

The Intercrete system also has good flexibility to allow for differential movement of steel and concrete

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Tank Base Sealing

Gap between concrete base and steel tank was sealed with an Intercrete system and top coated with

Interfine 691.

The system creates a flexible waterproof seal which will allow for the different movement of the steel and concrete

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Concrete

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

International Paint supply the full range of products and lining to repair and protect concrete containment areas in the Oil & Gas Industry.

The cementitious rebuilding products can be used to repair damaged and degraded concrete.

The linings can be used in areas of continuous immersion, such as storage tanks and also in areas of splash and spill such as secondary containment areas.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intercrete

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intercrete

Intercrete was launched in 2012

Intercrete are cementitious, water based products

Intercrete products are designed to repair and protect concrete

Intercrete offers an excellent barrier to water along with high compressive strength and adhesion.

No primer required. The products are applied to concrete which is wet with clean water meaning that you do not need to wait for the concrete to dry before applying Intercrete.

Usually used to repair and protect concrete tanks

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

59

Intercrete 4801

High build structural repair mortar.

80mm in one application to overhead and vertical repairs.

Can be bulked out with stones for deeper holes.

No primer required.

Applied to a water saturated substrate.

Demonstration Video

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intercrete 4820

Waterproof protective render, pore filler & fairing coat.

Withstand water pressure up to 10 bar.

Maximum thickness 6mm. Can be featheredged to 0mm.

Used to fill blow holes etc.

Applied by trowel can be bagged rubbed.

Demonstration Video

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Intercrete 4840

Cementitious coating

Waterproofing cementitious coating

Resists 10 bar water pressure (positive and negative)

2mm is equivalent to 100mm concrete cover

Flexible withstand thermal expansion and contraction

Spray applied for large areas

Can be applied to damp and green concrete

25 years track record

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Secondary Containment area protection

The concrete floor area around tanks containing 31% hydrochloric acid and 33%

Sodium hydroxide was protected with Ceilcote 380 primer and

Ceilcote 232 novolac vinyl ester chemically resistant lining.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Drain Channel Sump

Oman

This sump in the Mechanical Vapour Compression (MVC)

Plant was suffering from attack by oily water from drain channels at a temperature of less than 100˚C

The damaged concrete was primed with Ceilcote 380 concrete primer, rebuilt with paste made of Ceilcote 380 mixed with powder and then coated with Ceilcote 222HT to provide long-term chemical resistance.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

New Construction Power Station

Flue Gas De-sulphurisation unit at a new build power station in

Saudi Arabia.

Ceilcote 242MR was selected to protect the absorber against the high temperature chemical attack.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Ceilcote 2000MR

Secondary Containment Area around this sulphuric acid tank was rebuilt and protected with Ceilcote 2000MR

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Ceilcrete

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

6

7

Chemical and effluent treatment

- Secondary containment

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Protection of chemical handling area

Ceilcote 2000 CeilLine

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Transformer Bunds

The client wanted to quickly seal electric transformer bunds to ensure that no leaking was possible and to prevent environmental damage.

One thick coat of Polibrid 705E was applied to the bund and hydro tested the same day

The flexibility of Polibrid allows it to move with the concrete substrate and not crack.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Pipelines

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Internal Coatings

Standard

UK DEF STAN

80-97

Description Cargo

Jet Fuel Jet Fuel

Approved Products

Interline 850

Suitable Products

Interline 399

Interline 984

MIL-C-4556E Jet Fuel

EI 1541 Jet Fuel

API RP5L2 Epoxy

Flowcoats

ISO 15741

Jet Fuel Interline 850

Jet Fuel Interline 984

Gas Intergard 272

Intergard 2272

NSF

N/A

Epoxy

Flowcoats

Potable

Water

Gas

Potable

Water

Approval

Oil pipeline Sour Oil

Intergard 272

Intergard 2272

Interline 850

Interline 925

Interline 975

Interline 984

Enviroline 376 F

Enviroline 405HT

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Interzone 485 – Workshop application

Interzone 485 - Ultra high build epoxy applied to the externals of buried pipeline in workshop.

Coating passes BS EN 10289 showing suitability for use in this environment.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Application Example –

Buried Pipeline

Interzone 485 - Ultra high build epoxy applied to the externals of buried pipeline in the field.

Coating tested to BS EN 10289 showing suitability for use in this environment

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Application Example –

Buried Pipeline

Externals of this buried natural gas pipeline required re-coating. The contractor recommended Enviroline 376F-30 cured epoxy novolac lining following 3 years successful experience using the product.

The quick cure of the coating allows quick back filling of the pipe and also reduces the good weather window required to apply the coating. This saved the customer money and allowed quick completion of the job.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

External Coatings

Standard Description Environment Approved

Products

ISO 10290 Polyurethane

External

Buried Interzone 1800

(under test)

Coatings

ISO 10289 Epoxy external coatings

ISO 12944 External coatings

Buried

ISO 21809 Field Joints Buried

Interzone 485

Interzone 1500

Above ground Interzinc 22 / 52

Intergard 475HS

Interthane 990

Suitable products

Enviroline 376 F

Enviroline 405HT

Interzone 954

Enviroline 124

Interzone 485

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Interline 925

Interline 925 was used to internally line 26,000 m² of water pipeline in India.

Interline 925 was spray applied using rotating airless spray equipment.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Case Histories- Oil & Gas Onshore

Oman Gas Corporation- Pipeline

Owner: Oman Gas Corporation

Applicator: Jindal Saw Ltd

Location: Gujarat

Project Finished: 2007

Coating: Epoxy Flowcoat

Area: 300,000m 2

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

CHARTEK 1709

FIREPROOFING

A real alternative to cement or concrete based fire protection

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Chartek 1709

Chartek 1709 is epoxy intumescent fireproofing

It gives protection against oil & gas fires for the onshore hydrocarbon industries

In a fire it forms an insulating layer to protect the steel from extreme heat

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

C1709 gives corrosion protection

Strong, durable material

30 years track record of corrosion protection

Epoxy market leader used by all major operators worldwide

No recorded failure due to the material itself

Fast application: no pins and no metal mesh

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

A real alternative to cementitious fireproofing

Concrete/cement fireproofing is porous

Allows corrosion to take place unseen

(Corrosion Under Fireproofing)

Requires regular crack repair and maintenance of topcoat

High cost of maintenance gives high lifecycle costs

Collapsed sphere due to corrosion under cementitious PFP

After fire buckling of steel column

‘protected’ by cementitous pfp

Corrosion of column web under cementitious PFP

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.

Summary

International Paint have the complete product offer for the Oil & Gas

Industry

International Paint have full range of traditional paint systems to protect structural steel and offer long-term performance.

Specialised products can be used to solve most difficult issues on site.

International Paint provide high levels of service to both owners and applicators whilst adhering to strict business principles practices from

Akzo Nobel.

All products supplied and technical advice and recommendations given are subject to our standard conditions of sale.

Any information given here is for guidance only and no representation or warranty is given as to its potential use.