Elements Of Aeronautics - Vel Tech Dr.RR & Dr.SR Technical

advertisement

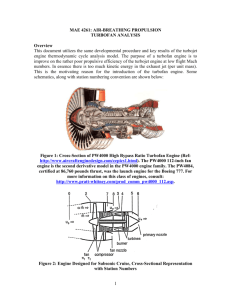

U3AEA04 ELEMENTS OF AERONAUTICS Mr. SYED ALAY HASHIM Assistant Professor Department of Aeronautical Engineering VEL TECH Dr. RR & Dr. SR TECHNICAL UNIVERSITY Chennai INDIA I to V UNIT POWER POINT PRESENTATION AIRCRAFT COMPONENTS TYPES OF WING 1. 2. 3. 4. 5. 6. 7. Monoplane Biplane Tandem wing Triplane Quadruplane Multiplane Canard wing SWEEP WING Leading edge extensions of various kinds AIRCRAFT HISTORICAL RECORDS Introduction AEROSPACE ENGINES • Comprehend the basic components of gas turbine engines and their basic operations • Comprehend the thermodynamic occurring in a gas turbine engines processes • Comprehend the support systems associated with gas turbine engines Gas Turbine Cycle Single stage Ideal gas turbine cycle GAS TURBINE CYCLE Two stage turbine cycle Gas Turbine Cycle Two stage Compressor and Turbine cycle Jet Propulsion Cycle In practical or actual cycle Entropy is not constant Jet Engine Basic Components Compressor • • Supplies high pressure air for combustion process centrifugal flow and Axial flow • • • Centrifugal Compressor Adv: simple design, good for low compression ratios (5:1), strong Disadvantage: Difficult to stage, less efficient, high frontal area Compressor Axial flow • Good for high compression ratios (20:1) • Most commonly used Turbine • Convert the kinetic energy into expansion work • It is used to drive the compressor as well as propeller shaft Comparison of Gas Turbine and Piston Engine Classification of Engine Engine Air Breathing Engine Non-Air Breathing Engine (Presents of Fuel and absents of Air (Using atm air to produced Power) Jet Engines Reciprocating Engines instead of Air + Oxidizer. Hypersonic vehicles, Operating Mach No : 15 to 20) (Propulsive thrust is produced by jet) Rocket Engine (No moving parts) Gas Turbine Engine Non-Gas Turbine Engine (Available moving parts like Compressor and Turbine) Turbojet Turboprop (No moving parts) Ramjet Scramjet Turbofan Turbo-shaft Pulsejet Turbojet Chemical energy is converted into mechanical energy 100% Thrust produced by Nozzle Operating Mach No: 1 to 2 Supersonic Aircraft (1 to 5) Turbofan 20 to 40% of Thrust produced by Nozzle 60 to 80% of Thrust produced by Fan Operating Mach No: 0.4 to 0.8 High Subsonic Aircraft (0.3 to 0.8) Turboprop 20 to 25% of Thrust produced by Nozzle 75 to 80% of Thrust produced by Propeller Operating Mach No: 0.4 to 0.65 Subsonic Aircraft (0.1 to 0.8) Turbo Shaft High pressure turbine is used to rotate HP & LP Compressor Low pressure turbine is used to rotate output Shaft No Thrust produced in the exit turbine gas Turbo Shaft Kinetic energy is converted to Shaft power 100% Thrust produced by Shaft Operating Mach No: 0.4 to 0.8 High speed Subsonic helicopter (0.3 to 0.8) Pulse Jet Made up of few moving parts Valved engines use a mechanical valve to control the flow of expanding exhaust, forcing the hot gas to go out the back of the engine through the tailpipe Starting the engine usually requires forced air and an ignition method such as a spark plug for the fuel-air mix. It can operate statically Rocket Engines A rocket is a machine that develops thrust by the rapid expulsion of matter A rocket is called a launch vehicle when it is used to launch a satellite or other payload into space Rocket engines are reaction engines The highest exhaust velocities It is used in missile Passenger airplanes Sl. No. Description Less Moderate High 1 Specific fuel consumption Turbofan Turboprop Turbojet 2 Noise Level Turbofan Turboprop Turbojet 3 Operating Mach No Turboprop Turbofan Turbojet 4 Take off Thrust Turbojet Turbofan Turboprop 5 Altitude Turboprop Turbofan Turbojet 6 Load Carrying capacity Turbojet Turboprop Turbofan 7 Specific Impulse Turbojet Turboprop Turbofan Thrust Equation Total Thrust = Momentum Thrust + Pressure Thrust mi=mj (mass flow rate) Inlet pressure = Exit pressure Thrust force is the forward motion of engine Factors Affecting Thrust PRESSURE TEMPERATURE DENSITY HUMIDITY ALTITUDE FORWARD VELOCITY Methods of Thrust Augmentation After burning High thrust for short duration It is used only in take-off (or) for high climbing rates Additional fuel is burning in the tail pipe between the turbine and exhaust nozzle It is increased the jet velocity Oxidizer-Fuel Mixture Increase the mass flow rate Evaporative cooling which produces higher pressure and higher mass flow rate Increase the compressor pressure ratio due to reduced compressor air flow Water and menthol or alcohol Mixture After burner Oxidizer-Fuel Mixture Evaporative cooling which produces higher pressure and higher mass flow rate Advantages of Gas turbine Engines • • • • • • • • Weight reduction of 70% Simplicity Reduced manning requirements Quicker response time Faster Acceleration/deceleration Modular replacement Less vibrations More economical Disadvantages of Gas Turbine Engines • • • • • Many parts under high stress High pitched noise Needs large quantities of air Large quantities of hot exhaust (target) Cannot be repaired in place TYPES OF FUSELAGE STRUCTURE FUSELAGE DESIGN WING STRUCTURE Thank you