Transportation

Operations

McGraw-Hill/Irwin

Copyright © 2010 by The McGraw-Hill Companies, Inc. All rights reserved.

Transportation operations involves the

following major topics

•

•

•

•

Transportation economics and pricing

Transportation administration

Documentation

Pricing

Video on Ethics and future of Transportation (9:00 min.)

http://www.youtube.com/watch?v=T_SXW7v97tQ

Video on future of shipping (2:54 min.)

http://www.youtube.com/watch?v=sigYFTP6YFg

9-2

Transportation operations seeks an optimal

balance between low cost and high service

• Transportation is single

largest element of logistics

cost

– Rising fuel costs

– Environmental cost of

carbon footprint

• Transportation managers

are responsible for

inventory to be positioned

in a timely and economical

manner

9-3

Transportation economics and pricing are

concerned with factors that drive cost

• An effective logistics strategy must understand four

interrelated topics

–

–

–

–

Economic drivers that influence rates

Costing methods to allocate costs

Carrier pricing strategy used to set rates

Rates and rating mechanics used by carriers

9-4

Economic drivers influence rates

•

•

•

•

•

•

•

Distance

Weight

Density

Stowability

Handling

Liability

Market

9-5

Distance is a major influence on cost

• Directly contributes to variable

expenses

– Labor, fuel, and maintenance

• Cost curve starts above zero

because of fixed costs

associated with pickup and

delivery regardless of distance

• However, rate of cost

decreases as distance

increases

– This is called the tapering

principle

Figure 9.1 Generalized Relationship between

Distance and Transportation Cost

9-6

Weight is the second major factor for most

transportation costs

• Cost per pound decreases

as weight increases until

the carrier vehicle is full

– Relationship starts again for

the next vehicle load

• Small loads should be

consolidated into larger

loads to maximize scale

economies

Figure 9.2 Generalized Relationship between

Weight and Transportation Cost/Pound

9-7

Density is the combination of weight and volume

• Volume is important

because vehicles are

typically constrained more

by cubic capacity than by

weight loaded

• Cost per unit of weight

declines as product

density increases

– Higher density products

allowed fixed transport

costs to be spread over

more weight

Figure 9.3 Generalized Relationship between

Density and Transportation Cost/Pound

9-8

Stowability is how product dimensions fit

into transportation equipment

• Odd package shapes and

sizes can waste cubic

capacity

• Items with rectangular

shapes are easier to stow

• Nesting refers to ability of

product to be placed in

itself or collapsed for

better stowability

9-9

Handling some products may require special

equipment

• Special equipment may

be needed to load and

unload trucks, railcars, or

ships

• How products are

grouped together in

boxes or pallets will also

impact handling cost

9-10

Liability includes product characteristics

that can result in damage

• Carriers must pay for

liability insurance or accept

financial responsibility

• Shippers can reduce their

risk by

– Improved packaging and

loading

• For example - pneumatic

dunnage

– Reducing susceptibility to

loss or damage

9-11

Market factors such as lane volume and

balance influence transportation cost

• Transport lane refers to

movements between origin

and destination points

– Carriers must find a

backhaul load or vehicle is

returned empty

• Imbalances in volume

between shipping points

can result in higher

transport costs

9-12

Variable costs change in a predictable, direct

manner in relation to some level of activity

• Variable costs in

transportation are only

incurred if you operate the

vehicle

• Transport rates must cover

these at the very least!

• Generally measured per

mile or unit weight or both

– E.g. per ton-miles

9-13

Fixed costs must be paid even when the

company is not operating

• Fixed costs are not

influenced by shipment

volume

– Includes vehicles,

terminals, rights-of-way,

information systems, and

support equipment

• Must be covered by

contribution above variable

costs on a per shipment

basis

9-14

Joint costs are created by the decision to

provide a particular service

• Typical example is the

implicit decision to incur a

joint cost for a backhaul

from a destination

– E.g. Big and Little Enos in

Smokey and the Bandit

• Significant impact on

charges

– Carrier quotations must

include implied joint costs

based on assessment of

back-haul recovery

9-15

Common costs are incurred on behalf of all

or a select group of shippers

• Terminal or management

expenses are typical

examples

• Usually allocated to

shippers based on level of

activity for that customer

– E.g. number of shipments

9-16

Carrier pricing strategies for setting rates follows

one or two of the following approaches

•

•

•

•

Cost-of-service strategy

Value-of-service strategy

Combination pricing strategy

Net-rate pricing strategy

9-17

Carrier pricing cost-of-service strategy

• Cost-of-service is similar to

cost-plus pricing strategy for

manufacturing

• Carrier estimates cost of

providing service then adds

on a percent profit margin

• Commonly used for pricing

transport of low value goods

or in highly competitive

situations

9-18

Carrier pricing value-of-service strategy

• Value-of-service price is based on

value as perceived by the shipper

rather than the carrier

• Higher margins than cost-of-service

pricing

• Depends on the value of the goods

being shipped

• Used for high value goods or when

no competition exists

– E.g. 1980’s FedEx overnight delivery

9-19

Carrier pricing combination strategy

• Combination price is set at

a value between cost-ofservice minimum and valueof-service maximum

• Most carriers use some form

of combination pricing

– Common in highly volatile

markets and changing

competitive situations

9-20

Carrier pricing net-rate strategy

• Net-rate is a simplified

pricing format made

possible by deregulation

• Established discounts

and accessorial charges

are rolled into one allinclusive price

• Pricing is tailored to the

individual customer’s

needs

UPS commercial:

“What can Brown do

for you?”

9-21

Rates and rating mechanics used by

common carriers

•

•

•

•

Class rates are the price in dollars

and cents per hundredweight to move

a specific product between two

locations

Classification is the grouping of

similar products into uniform classes

that are assigned a rating

Rate determination is based on the

classification rating, shipment origin,

and destination

Cube rates replace the 18 traditional

freight classifications of the NMFC

with five cube groupings

– Still in development

•

Commodity rates are for a large

quantity of product which moves

between two locations on a regular

basis

– Typical for most rail freight today

•

•

Exception rates are special rates to

provide prices lower than the

prevailing class rates

Special rates and services include

– FAK rates, Joint rates, Transit

services, Split delivery, etc.

9-22

Three factors determine the base rate

• How much are you shipping?

– Truckload (TL) or

– Less than truckload (LTL)

• What are you shipping?

– Determines freight class

• How far are you shipping from origin to destination?

– Determines rate table

9-23

Special rates and services

•

•

•

Freight-all-kind (FAK) rates allow a

mixture of different products to be

transported under a negotiated rating

Joint rates can be negotiated if

shipper needs to use a combination

of carriers

Transit services permit shipments to

be stopped at an intermediate point

between origin and destination for

special processing

•

•

•

Diversion and reconsignment

allows changing the destination

and/or consignee prior to arrival at the

original destination

Split delivery is delivering portions of

a shipment to multiple destinations

Product storage services

– Demurrage (rail) charge for holding

a railcar for more than 48 hours

before unloading

– Detention (motor) charge for holding

a truck for more than a few hours

before unloading

9-24

Transportation administration activities include

•

•

•

•

•

•

Operational Management

Consolidation

Negotiation

Control

Auditing and claims administration

Logistical integration

9-25

Key elements of operational management

• Equipment scheduling and yard

management

• Load planning

• Routing and advance shipment

notification (ASN)

• Movement administration

• Transportation Management System

(TMS)

– An integral information technology

solution to help oversee day-to-day

activities

9-26

Consolidation

• Consolidation is combining LTL or parcel shipments

moving to a general location

• Shift to “response-based” logistics has made the industry

rethink consolidation

• Two groups of techniques

– Reactive approach does not attempt to influence composition and

timing of transportation movements, but reacts to shipments as

they come

• Example is UPS nightly sorting of package freight for intercity movement

– Proactive approach includes preorder planning of quantity and

timing with the shipper to facilitate consolidated freight movement

9-27

Negotiation

• Seeking win-win agreements

where both shippers and

carriers share transportation

consolidation and productivity

gains

• Both parties seek the lowest

total logistical cost consistent

with the shipper’s needed

service level (i.e. delivery time)

9-28

Control responsibilities include tracing, expediting

and driver hours administration

• Tracing is procedure to locate

lost or late shipments

– i.e. tracking with RFID and GPS

systems

• Expediting involves the

shipper notifying carrier that it

needs a specific shipment to

move quickly and with no

delays

• Tracking driver hours of

service (HOS) to comply with

federal regulations

9-29

Auditing and claims administration is needed

when services are not performed as promised

• Auditing is checking freight bills

to ensure accuracy

– Preaudit determines proper charges

prior to payment

– Postaudit does the same after

payment

• Claims can be

– Loss and damage resulting from

poor performance

– Overcharge/undercharge when

amount billed is different from

expected

9-30

Logistical integration is the primary role of

the traffic manager

• Integration is finding the

best combination of

packaging, selection of

carrier, mode and

consolidation for lowest

total logistical cost

consistent with the

shipper’s service needs

9-31

Primary purpose of documentation is to protect all

parties involved in the transaction

• Bill of lading is the basic document utilized in purchasing

transport services

– Serves as a receipt and documents products and quantities

shipped

– Specifies terms and conditions of carrier liability

• Freight bill represents a carrier’s method of charging for

transportation services rendered

– Can be prepaid or collect

• Shipment manifest lists the individual stops or consignees

when multiple shipments are placed on a single vehicle

9-32

Pricing practices have a direct impact on

logistical operations

• Traditionally, logistics pricing

was “bundled” into the price

for a product or service

• Trend has been to debundle

these charges so they

become separate and visible

to the customer

• Focus is still on delivering

value to the customer

9-33

Pricing fundamentals of F.O.B. pricing

• F.O.B (freight on board) pricing

– F.O.B. origin—seller states price at point of origin, and

agrees to load a carrier, but assumes no further

responsibility. Buyer selects carrier and mode, pays

transportation and assumes the risk for in-transit loss or

damage

– F.O.B. destination—seller arranges for transportation

and adds charges to the sales invoice. Title does not

pass to the buyer until delivery is completed

9-34

Three different payment options for each

F.O.B. price

Figure 9.5 Terms of Sales and Responsibilities

9-35

Pricing fundamentals of delivered pricing

• Delivered pricing—the seller includes transportation in the

product price

– Single zone delivered pricing

• Buyer pays a single price regardless of where they are located

– Example, USPS First class letters

– Multiple zone pricing

• Seller charges different prices for different geographic areas

– Parcel carriers use this.

– Base point pricing

• Final delivered price is determined by the product’s list price plus

transportation cost from a designated base point

9-36

Illustration of different net returns using a

base-point pricing system

Figure 9.6 Base-Point Pricing

9-37

Pricing issues

• Potential discrimination—Zone pricing may be discriminatory

because some buyers pay more than the actual transportation cost

while others pay less

– Sellers have to be careful about Federal price discrimination laws

• Quantity discounts—may be discriminatory against smaller buyers

• Pickup allowances—discounts given if buyer picks up the shipment

themselves

• Promotional prices—special prices given for large sales promotions

– EveryDay Low Pricing (EDLP) is a collaborative pricing framework developed

by Wal-Mart

9-38

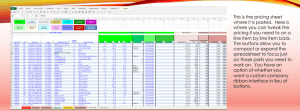

Menu pricing system consists of three

components

• Platform service price is expected to be paid by all

customers, whether or not they require or desire the

specified services

– Must establish the basic service platform to be offered all

customers

• Value-added service costs are specific upcharges for

performing customer requested value-added services

– E.g. for customized unit loading such as configuring retail-ready

unit loads

• Efficiency incentives encourage customers to comply with

specified practices that reduce logistics costs

9-39