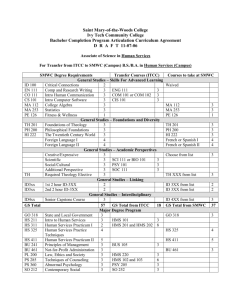

overview of management systems principles

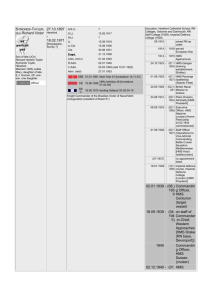

advertisement

LECTURE NOTE HOUSE OF TQM WORLD-CLASS MANUFACTURER TOTAL QUALITY MANAGEMENT Capable and Efficient PROCESSES Involved, Committed & Creative PEOPLE Delight customers PRODUCTS Mistake-free ● Fast ● Lean ● Flexible ● Environment-friendly TQM CORE INITIATIVES Continuous Improvement Teams Quality Management System Autonomous Maintenance & 5S TQM EHS Management System Innovative Creative Circle Lean Manufacturing Employee Suggestion Scheme Training & Education TRANSFORMATION Continuously Steering Towards Excellence AMS – 5 FOCUS TARGET QUALITY COST 1-Elimination of customers downtime 2-Reduction of in-process ppm 3-Reduction of customer reject ppm 4-Reduction in suppliers in-coming parts ppm 5- Certified to International standards. 6-Reduce cost of quality MORALE 1-Improve in Employee Satisfaction Index 2-Increase in number of employees suggestions and implementations. 3-Improve in employee rewards 4-Improve in the training hours per employee 5-Increase in numbers of improvement projects. 6-Reduce employees absenteeism & turnover 1- Improve profit 2- Reduction of: a) Raw material, WIP and FG b) Utilities costs c) Space usage d) Overtime cost e) Maintenance cost f) Labor employed g) Equipment downtime h) New investment 5 FOCUS TARGETS EHS 1-Zero accident 2-Compliance to DOE & DOSH regulation 3- Certify to OHSAS & EMS 4-Increase S.H.E awareness 5-Good housekeeping & improve 5S index. DELIVERY 1-Reduction of through put time 2-Reduce non-value added work 3- Increase stock turn 4-On-time-delivery to customer 5-Reduction of lot size 6- Improvement of OEE. 7- Change-over time 8- Optimization of logistic DETERMINING THE AMS PRINCIPLE 5 FOCUS TARGETS VALUES VISUAL MANAGEMENT TOTAL EMPLOYEE INVOLVEMENT & DEVELOPMENT LONG TERM BUSINESS THINKING QUALITY RIGHT 1ST TIME WASTE ELIMINATION STANDARDIZATION PRODUCTION LEVELLING PULL SYSTEM brainstorming FLEXIBILITY REFERENCES a) TOYOTA Production System b) MERCEDES Production System c) BOSCH Production System d) ISUZU KAIZEN Network System e) FORD Production System LONG TERM BUSINESS THINKING VISUAL MANAGEMENT TOTAL EMPLOYEE INVOLVEMENT & DEVELOPMENT QUALITY RIGHT 1ST TIME EVERY TIME STANDARDISATION PRODUCTION LEVELLING FLEXIBILITY WASTE ELIMINATION PULL SYSTEM HOUSE OF AMS QUALITY RIGHT 1ST TIME EVERY TIME STANDARDISATION PRODUCTION LEVELLING FLEXIBILITY WASTE ELIMINATION 5 FOCUS TARGET PULL SYSTEM HMS STRUCTURE VISUAL MANAGEMENT TOTAL EMPLOYEE INVOLVEMENT & DEVELOPMENT LONG TERM BUSINESS THINKING KEY PERFORMANCE INDICATORS (KPI) 13 INITIATIVES HMS 9 PRINCIPLES (OVERVIEW) P1. Long Term Business Thinking Business decisions are guided by long term thinking and being embraced by every employee. P2. Total Employee Involvement & Development Committed and engaged employees are involved in their task with sense of ownership and responsibility. P3. Visual Management Make visible status, deviations, and install self explaining control systems and procedures. P4. Quality Right 1st Time Every Time Deliver right quality to the next customers by avoiding nonconformity through preventive actions all the time. P5. Pull System Produce based on actual customer demands and avoid over production throughout the processes. P6. Waste Elimination Continuously improve to eliminate all type of wastes. P7. Flexibility Flexible with regards to human resources, processes, logistics & volume variations. P8. Production Leveling Eliminate unevenness in production scheduling and level out workload of manufacturing and service processes. P9. Standardization Standardize for consistency, maintain predictability, regular timing and consistent output of processes. HMS INITIATIVES STRATEGIC MANAGEMENT PROCESS OWNERSHIP THINKING 5S VISUAL MANAGEMENT Strategies that involved business plan, KPI, investment, customer satisfaction, employee satisfaction and product analysis. To develop K-Worker, meaning that workers having knowledge in technical, method, application, human and social responsibilities. Activity that make working environmental tidy and systematic . To enable all the status of process or system to be visualized and understand without explanation. i.e. Visual Board, Footprint , Obeya, etc. HMS INITIATIVES QUALITY MANGEMENT SYSTEM 3 TYPES OF CERTIFICATION : (a) TS16949 (b) ISO14001 (c) ISO 18001 EMPLOYEE SUGGESTION SCHEME To encourage employee to give and idea or suggestion for improvement. SMALL GROUP ACTIVITIES Employee involvement in continuous improvement program for QCDMS. JUST-IN-TIME (JIT) Production process with the method of ‘One piece continuous flow’’ without extra raw material or finish good product (zero inventory). HMS INITIATIVES AUTONOMOUS MAINTENANCE (AM) VALUE STREAM MAPPING AUTONOMASI (JIDOKA) SINGLE MINUTE EXCHANGE DIE (SMED) Activity that encourage machine operator to carry out basic maintenance on his/her machines. Objective of AM are zero defect, zero downtime and zero accident. A method that use to analyse overall production process starts from supplier, production and customers. One of the method to use for controlling the product quality (quality control process) by using certain methods (engineering). Quick changeover method using for model change process from old method to new within the shortest time. 12 HMS INITIATIVES FLEXIBILITY Flexibility Production System is the system that able to accommodate the variable production planning either it was plan or not. There are two category of flexibility system : 1) Resource flexibility – includes the flexibility of the system to produce new product.. 2) Routing flexibility – includes variety of line and system that able to produce high productivity and capicity at any time required..