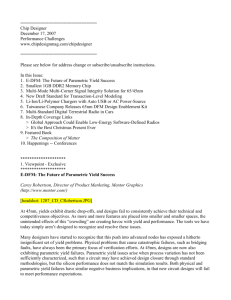

Chapter 9, 10, 11 - Ivy Tech -

advertisement

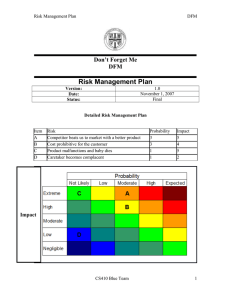

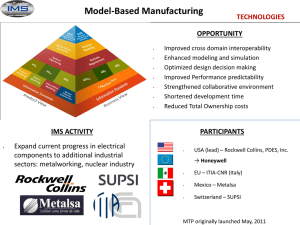

Product Architecture, Industrial Design, Design for Manufacturing Chapter 9: Product Architecture Product Architecture has 2 elements: Functional – individual operations and transformations that contribute to the overall performance of the product Physical – parts, components, and subassemblies that implement the product function Creating modules or building blocks can help in organization and manufacturing Implications of the Architecture Decisions of architecture can affect many issues: Product change Upgrades, Add-ons, Adaptation, Wear, Consumption, Flexibility in use, Reuse Product variety Component standardization Product performance Manufacturability Product development management Examples Exhibit 9-4 pg 169 – Swatch watch Example – F-150 Example – Sport Trac Establishing Architecture Steps 1. Create a schematic of the product Layout of the components, their hierarchy and interactions 2. Cluster the elements of the schematic Group the components into clusters based on: Geometric integration and precision Function sharing Capabilities of vendors Similarity of design or production technology Localization of change Accommodating variety Enabling standardization Portability of the interfaces Establishing Architecture Steps 3. Create the rough geometry Create a rough, basic 3-D and 2-D sketches 4. Identify the fundamental and incidental interactions Likely the functional groups or clusters will be assigned to the respective areas of expertise for further design. As a cross functional team the interaction between groups should be know Fundamental interactions – interactions of components based on function of the product Incidental interactions – interactions that arise from physical arangement Delayed Differentiation On occasion variations in architecture will be delayed until further in the Supply Chain. Examples – voltage components, product variation or customer ordering Design evolves around the customized group to allow for the options Chapter 11: Design for Manufacturing Detail design decisions have a substantial impact on final product quality and cost Development teams face multiple and often conflicting goals Important to have metrics to compare alternative designs Dramatic improvements often require substantial creative efforts early in the process Well-defined method makes the decision-making process much easier DFM Requires a cross-functional team, internal to the organization and external experts, as well as vendors Performed throughout the process Overview: 1. 2. 3. 4. 5. Estimate the manufacturing costs Reduce the costs of components Reduce the costs of assembly Reduce the cost of supporting production Consider the impact of DFM decision on other facors Estimate the Manufacturing $ Manufacturing $ = ∑Input costs Raw material Purchased components Employees effort Energy Equipment Component $ Assembly $ Overhead $ Estimating the Manufacturing $ Fixed $ vs. Variable $ Fixed - $ spent regardless of the quantity of products sold Variable - $ spent that changes based on the quantity of products sold Estimate the $ of standard components Estimate the $ of custom components Estimate the $ of assembly Estimate the $ of overhead cost Reduce the $ of Components Understand the process constraints and cost drivers Redesign components to eliminate processing steps Choose an appropriate Economic scale Standardize components and processes Reduce the $ of Assembly - DFA Integrate parts Maximize ease of assembly Parts inserted from the top of the assy Part is self-aligning Part does not need to be oriented Part requires only one hand for assy Part requires no tools Part is assembled in a single, linear motion Part is secured imediately upon insertion Reduce the $ of Supporting Production Minimize systemic complexity Error proofing Consider the impact of DFM The impact of DFM on development time The impact of DFM on development cost The impact of DFM on product quality The impact of DFM on external factors Component reuse Life cycle cost