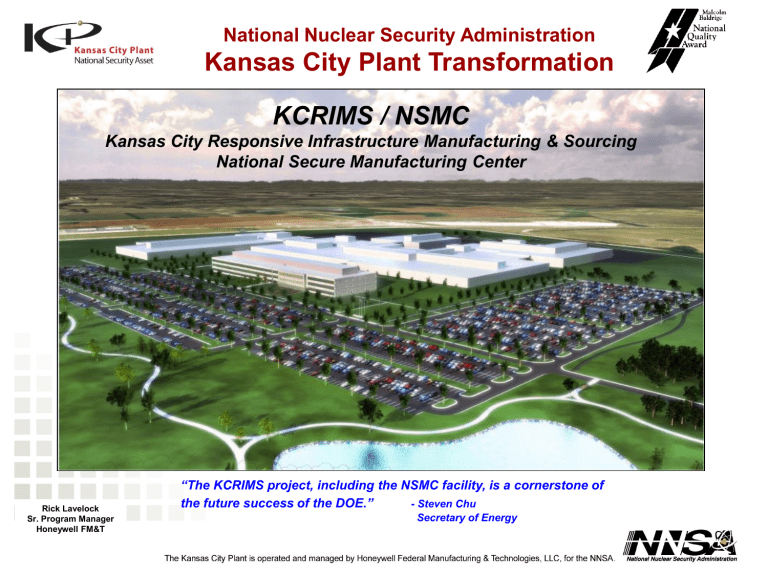

KCRIMS / NSMC Program Timeline

advertisement

National Nuclear Security Administration Kansas City Plant Transformation KCRIMS / NSMC Kansas City Responsive Infrastructure Manufacturing & Sourcing National Secure Manufacturing Center Rick Lavelock Sr. Program Manager Honeywell FM&T “The KCRIMS project, including the NSMC facility, is a cornerstone of the future success of the DOE.” - Steven Chu Secretary of Energy KCRIMS / NSMC Program Timeline Calendar Years Shown SAIC Alternate Site Study KCRIMS Draft Business Case Facility Acquisition Report D’Agostino Congressional Testimony NEPA EA Decision RI Roadmap 3 4 1 2 1 2 2005 3 SEAB Report 4 Site Selection & Press Release 3 4 1 2 4 1 2 2006 Strategy Team NNSA January Process 3 Functional Teams NEPA NOI CD-0 Restart Solicitation 3 Draft EA Public Comment Ends 4 1 2 4 1 2 2007 3 CD-1 Joined GSA for Facility Acquisition 1 2 4 1 2 NEPA Appeal Dismissed Financing Secured NEPA Suit Win 3 4 1 4 1 2009 3 IPR Mitigated GSA FONSI Congressional Bid Bust Approval OMB Approval First KCRIMS Transformation Plans 4 2008 Solicit Developers KCRIMS Final Business Case 3 Developer Selected BAFO Short List NEPA Briefs Completed Bids Received NRDC NEPA Suit Filed NSMC MOA 2 3 2010 3 Lease / PIEA Negotiations 2 3 PIEA Finalized Lease Agreement Lease Signed Construction Start KCRIMS Transformation Plan Elements 2005 KCP 2014 KCP KCRIMS Maintenance Of Cold War Era Capacity and Redundant Capabilities Commercial Supply Base • 65 years old • 3.1 M ft2 • 2950 employees • High fixed costs • Low utilization • 55% outsourced Revised Governance Strategic Sourcing & Sizing Enablers Business Process Transformation New Facility Transformation Actions Transformation Elements Integrated Interdependent Enterprise Responsive Infrastructure Commercial Supply Base • Modern Infrastructure • 1.0 M ft2 (DP Mission) • 2300 employees (given same workload) • Low fixed costs • Reconfigurable • 70% outsourced Reduces footprint over 50% and operational costs by 25% Current Bannister Federal Complex NNSA 3.1 M ft2 Controlled 2.8 M ft2 In Use GSA & Tenants 2.0 M ft2 Controlled National Security Campus Site Plan For the 20 year lease, the real estate assets will be: • Owned by: PIEA • Designed, built, financed and maintained by: CPZ • Leased by: GSA • Occupied & operated by: NNSA/Honeywell Facilities design for flexibility to accommodate all plausible stockpile scenarios. Site Construction Progress KCP Transformation Schedule Summary 2006 2007 2008 Phase 1: 2009 2010 2011 2012 2013 2014 Facility Acquisition & Business Transformation 2015 Cost $138M Final IT & Security Install Private Construction Phase 2: Rolling 19 Month Relocation Occupancy Project Including Relocation Phase 3: Bannister Disposition Planning & Execution $705M (Private Funds) $291M ($264 KCRIMS) ($27 NSMC) $85M _______ Integrated Phases for a Comprehensive Transformation $1,219M KCP Operating Requirements Before Transformation After Transformation (1/30/2007) 1/31/2008 1/31/2009 1/31/2010 DOE Orders 87 30 31 31 41 DOE Regulations 13 5 5 5 5 DOE Requirements 30 11 10 10 11 NFPA 14 12 12 12 2 Standards/Codes 8 8 8 6 6 Other 8 7 7 7 7 Total 160 73 73 71 72 Directive 55% Reduction in Operating Requirements KCRIMS Status Outsourcing Build Aheads 204/204 Parts = 100% Complete 10,352 Pieces Complete = 117% of Plan 12000 10000 Actual 8000 Committed 6000 4000 2000 0 1 2 3 4 1 2 3 4 1 2 FY09 FY08 Inventory Reduction Cumulative Labor & Expense Savings = $236M Space Requirements Reduced 63% Escalated FTI Cost Targets 4 FY10 Business Process Transformation 400 3 300000 3000 FY10 Actual Costs 350 FTI Headcount Targets FY10 Q4 Headcount 250000 2500 300 200 1500 150 1000 Headcount Millions $ 250 Square Feet 200000 2000 150000 100000 50000 100 500 50 0 0 06 07 08 09 10 11 12 13 14 15 16 0 2005 2006 2007 2008 2009 2010 2011 2012 2013 Plan 303210 178000 158000 141000 128000 112300 97800 80800 60000 Actual 196691 178000 157800 140800 127000 111900 FY yr end KCRIMS Strategic Sourcing & Sizing Strategic Sourcing and Sizing Plan: NNSA Mission Space Manufacturing Space Administrative Space Total Usable Space Make Parts (approx) Buy Parts (approx) From 1.26 M 1.84 M 3.10 M To 0.65 M 0.35 M 1.00 M From 3800 (46%) 4400 (54%) To 1000 (35%) 1800 (65%) Note: Changes in total numbers due to W80 and B61 requirements changes. Major Sourcing Activities: • Plating • Cables • Injection, Compression, & Transfer Molding • General Machining • RTV Silicone & RTV Desiccant Molding • Printed Wiring Assemblies • Thermoforming Major Process Changes: • Liquid Spray Paint changing to Powder Coating • Repackaging/Testing Carcinogen encapsulant FTI Accomplishments to Date 1. Shut down the Flexible Manufacturing System (FMS) 11. Transitioned HR & Staffing to HON Corporate model 2. Eliminated the on-site Fire Department 12. Consolidated over 90 software applications 3. Eliminated the Emergency Operations Center 13. Implemented Engineering Support Specialist 4. Closed down and outsourced the Plating Department 14. Consolidated IT servers 5. Implemented additional outsourcing of products 6. Implemented new IT tools for Finance and Program Management 7. Consolidated store rooms/reduced inventory 8. Implemented Honeywell Operating System (HOS) 9. Implemented Fact-Based Quality (FBQ) 10. Executed co-sourcing plan for IT services 15. Outsourced staffing administrative support 16. Implemented a facilities pause plan 17. Outsourced Medical Services and Carpenter Shop 18. Consolidated Waste Management Functions 19. EDSV Data Center shut down Transition Governance Structure NNSA HQ NNSA KCSO Honeywell Corporate Oversight Transition Approval Committee (TAC) Chris Gentile Robin Stubenhofer Bill Ross David Feather Sending Team Security Mike Ginder Steve Zvacek Transition Process Expert Chris Gentile / Bill Ross Transition Leads NSMC Production Production Linda Dan Wright HSE Sourcing Grote Don Linda Fitzpatrick Wright Facilities Mike Ginder Bart Stuckey Gloria Zarrella Brian Fischer Jeff Fuller * * * Brad Hughes * * IT John Engel Philip Clark Biz Ops Kevin Baughn HR Gina Angello Lobaugh * * PM Robert Repine Quality Rick Vanhoose ISC Curtis Mears New Facility Dan Fritts Jim Jeffries Relocation Dale Lock Bridge Functions Transition Program Management KCRIMS - Rick Lavelock FTI – Steve Halter NSMC – Steve Halter NSMC Growth – Dave Lowe Integrated Project Planning – Diana Blackburn* Communications – Sharon Robinson Red denotes NSMC leader or co-leader * denotes NSMC POC added to team NSMC Production Production Linda Lee Wright HSE Facilities Hoover Curt Denny Fulmer Valle Bart Stuckey * * Security Russel Bruch Steve Zvacek Kurt Lorenzen * * IT John Engel Philip Clark Biz Ops Kevin Baughn HR Gina Angello Lobaugh * * PM Robert Repine Receiving Team Quality Rick Vanhoose ISC Rick Vanhoose KCRIMS Strategic Sizing Summary Function Delivers reductions in infrastructure costs while fulfilling NNSA mission requirements Current (sq. ft.) Future (sq. ft.) Plating Facility 22,252 - Refurbishment & Dismantlement 20,589 12,000 Rubber & Plastics Manufacturing 96,646 38,400 Paint & Heat Treat 24,533 10,000 Machining & Gas Transfer Systems 206,293 102,500 Assembly & Electrical Fabrication 227,583 162,450 Trailers 34,642 - Special Material Production 25,256 22,300 Purchased & Other Inspection 44,125 34,500 160,898 73,300 Test Equipment, Gage Support & Metrology 66,240 29,700 Packaging & Shipping 27,604 20,800 303,210 60,000 1,259,871 565,950 Labs & Engineering Labs Storage Areas Sub - Total Allocated White Space (Included Above) 21,050 Unallocated White Space 62,800 Total Manufacturing Space 628,750 Relocation Planning Macro Plan Update Results – – – – Update to overall & phase durations – Move Phases: 105: KCRIMS – 100; NSMC - 5 Changes/Additions to the Macro Plan (i.e. equipment quantities) Confirmation of departmental sequencing Factors in resource constraints • Move Duration – Start dates following Security Transitions (Two months after bldg completion for KCRIMS, Four months for NSMC) • KCRIMS: January 23, 2013 – August 7, 2014 (391 working days) ~18.5 Months • NSMC: September 10, 2013 – January 23, 2014 (93 working days) ~ 4.5 Months KCRIMS/NSMC Project Summary Reduces KCP operational cost by $100M annually (FY06 dollars) Reduces KCP total footprint by over 50%, weapons funded space by 2/3rds Project has positive cash flow (savings > costs) for entire duration Reduces energy consumption by over 50%, LEED Gold sustainability Flexible to accommodate any all anticipated stockpile scenarios Lease allows easy adaptation of future NNSA business model Comprehensively planned to assure schedule deliveries Full and robust risk management program Provides 1500 construction jobs and generates $1.2B of near term stimulus Project Demonstrates Responsible Government KCP National Security Campus Questions?