to presentation.

advertisement

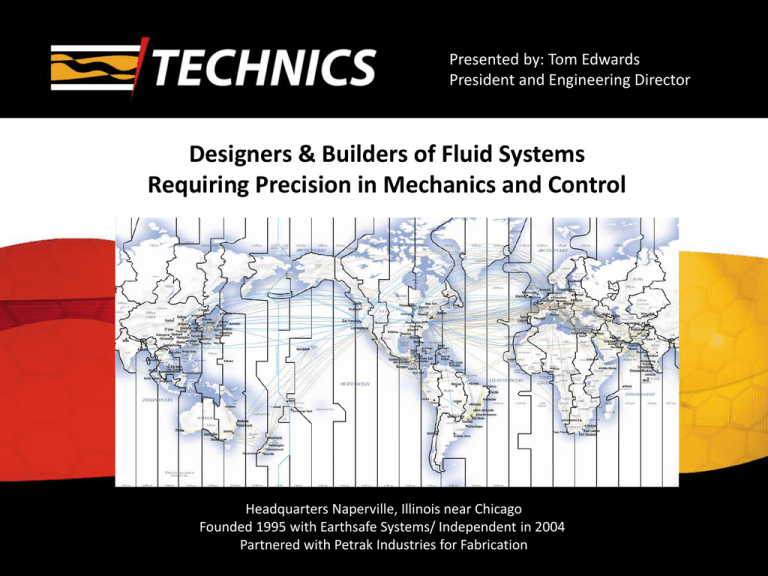

Presented by: Tom Edwards President and Engineering Director Designers & Builders of Fluid Systems Requiring Precision in Mechanics and Control Headquarters Naperville, Illinois near Chicago Founded 1995 with Earthsafe Systems/ Independent in 2004 Partnered with Petrak Industries for Fabrication Focus Fluidics for Research & Development • Small Scale Pilot Plants • Pressure Test Stands • Hose Permeation • Liquid Thermal Management • Fuel Conditioning Systems • Combustion Gas Blending Some Customers • Automotive: Ford, GM, Toyota, Honda, Nissan • Defense: General Dynamics, BAE, Honeywell • Basic Research: NASA, Argonne Laboratories, Fermi Laboratories, SAIC • Also: BP, Lubrizol, Siemens, Bosch, Textron Solutions for the Oil & Gas Industry • Blending Systems • Tank Farm Automation • Process Design • Control System Design • Software • Fabrication • Commissioning Mechanicals for Worldwide Deployment Varying Standards Varying Climates • Metric or Imperial Flanges & Piping • Tropics • API, ASME, GOST • Temperate Climates • Shipboard or Seaside • High Temperatures • Low Temperatures • Sand Storms • • • • • • 30,000 SF Shop 20 Ton Overhead Crane 12 ASME certified Welders ASME B31.1 & PMI Experts in stainless steel and alloys Low pressures to 500 BAR Process Control Systems • PLC’s: Allen Bradley, GE Fanuc, Telemechanique / Modicon, Siemens, Honeywell • CompactRIO reconfigurable embedded control and acquisition system • NEC, IEC, ATEX, NFPA, Cenelec, CSA, NEMA LOGOS Software for Worldwide Deployment Both Simple and Complex Interfaces User Defined Multiple Languages Terminal Blending Process Ethanol, Methanol, Bio-Diesel, GTL • Use of wild stream technique. • Use of flow meter on blend allows dual use as custody transfer meter. • Flow Must be mass or corrected for temperature and sometimes pressure. • Typically have low turndown requirements • Pump must be suitable for high vapor. • Use of Pump for flow control simplifies system and has very accurate control. • Static Mixer for homogenization but more importantly provides a representative sample for analysis. • These systems use bench top analyzers. Terminal Blending Process Ethanol, Methanol, Bio-Diesel, GTL Terminal Blending User Interface (Simple) Blending processes for RVP, RON, L/V • Blending based on mass using coriolis meters • Very High Turndowns (100:1) • On Line analyzers with Fast Loop • More complex algorithms so we use enhanced processors • Maintaining Liquid Phase • Preliminary diffusion then static mixers for representative sampling Butane Blending Butane: $1.50 per Gallon Gasoline: $3.00 per Gallon Profit: $1.50 per Gallon 1) RVP Requirements Change throughout the year 2) RVP of Pipeline less than mandated Maximum 3) If Allowable RVP = 10.0 psi and Pipeline RVP = 9.7 psi 4) Solve Mpetrol x (9.7) + Mbutane(52) = Mtotal (10.0) 5) If Mpetro= 1,000,000 then Mbutane = 7,000 Lubricant Blending • Hundreds of different formulas which change day by day • Highly Viscous materials • High Variation in component temperatures, viscosities • Highly susceptible to cross contamination • Contains some very low 0.05% additive Rates LOGOS Enterprise for Lubricant Blending Tank Farm Automation Technics has designed and automated tank farms for terminal operations as well as research and specialty transportation Amsoil Lubricant Plant BASF Engine Testing Nissan Automotive Assembly Plant Tank Farm Automation LOGOS Tank Farm Module works as a stand alone or integral interface with the blending process system. Information on the tank geometry & alarm setpoints and the material properties of its content are retrieved from the database and presented to operators and supervisors. •An array configuration allows new tanks to be easily added •Works with any tank geometry. •API Temperature compensated volume. •Works with any type level transmitters. •Retains past contents of tanks. Tank Historian • Inventory reports can be generated daily, weekly, or monthly at a selectable time of day. • Alarm notification and logging • Retains Pump Data like hours of operation and faults Tank Farm Database • Communicates with a wide variety of databases including SAP, Access, Oracle, and Excel. Customers • • • • • • • • BP BASF South Refineries Company Oilibya Boeing General Motors Ford Motor Company NASA Glenn Research Center • General Dynamics • Toyota Motors • Textron • • • • • • • • • • • • Honeywell Aerospace Continental AG US Army SAIC Siemens Automotive Eagle Picher Honda Motors Invensys Magneti Marelli US EPA Mark IV Automotive United Defense • • • • • • • • • • Pratt & Whitney United Technologies Nissan Motors US Oil Argonne National Laboratories Fermi Accelerator Laboratories TI Automotive Textron Kia Motors Eaton Countries • • • • • • • • • United States Canada Mexico South Korea China Australia Ethiopia Iraq Portugal