Documentation

Energy Efficiency Engineering

Ltd.

GAS FIRED EQUIPMENT FIELD

APPROVALS

PART2

Jozef Jachniak, P.Eng.

What will we talk about today?

• Part 1 Review

• Review Compliance Requirements

• Who is Responsible and For What?

• Who is Safety Code Officer?

• Who Else May Require Compliance?

• What Does Alberta Gas Code Regulation Require?

• Who is the CSA B149.3 For?

• Who is the CSA B149.1 For?

• What is the CSA B149.1 All About?

• What is an Inspector Looking For?

What will we talk about today? (cont.)

• What Is the Objective of ENEFEN Field Approval

• What Does ENEFEN Field Approval Consist Of?

• How Do We Do Field Approvals?

• Introduction to ENEFEN Database

• How do We Do Design and Engineering?

• Engineering Calculations

• Quality Control and Safety Compliance

• The End Result

Part I Review

• Introduction to ENEFEN

• What does ENEFEN do?

• Why are Field Approvals required?

• Safety legislation(s) behind Field Approvals

• Which codes do we have to comply with?

• What does CSA do?

• Who is AHJ (Authority Having Jurisdiction)

• Who is IB (Inspection Body)

Part I Review (cont.)

• What is the Province Wide Variance all about?

• Who is responsible for compliance?

• Non-compliance is an offence

• Penalties can be imposed (monetary and jail)

• Bill C-45 assigns criminal liability for accidents to individuals at organizations

• Uncertified appliances and equipment require special inspection and approval

• What is the difference between “certification” and “approval”

Part I Review (cont.)

• Who can do Field Approvals?

• What is the accreditation all about?

• How about P.Eng. doing a Field Approval?

• Is stamping of a drawing sufficient?

• What documentation is required?

• Who will check it?

• What will happen if there is no proof of Field

Approval?

• How about GRANDFATHERING?

Review of Compliance Requirements

• Primary Compliance is with the Provincial Act(s)

• Alberta Safety Codes Act requires compliance with:

• Amusement Rides Standards

• Building Code

• Electrical Code

• Elevating Devices Code (including Ropeways)

• Fire Code

• Gas Code

• Plumbing Code

• Pressure Equipment Safety

• Private Sewage Disposal Systems

Who is Responsible?

• Minister (co-ordinate and encourage)

• Owner (ensure compliance, maintenance, safety)

• Designer (ensure compliance, submit for review or registration, notify if deregistered)

• Manufacture (ensure compliance)

• Contractor (ensure compliance)

• Vendor (do not advertise or sell, lease or dispose of if non compliant, provide warnings if non-compliant)

• P.Eng. (ensure compliance)

• COMPLIANCE WITH ACT !!

Who is Not Liable?

• Crown

• Council or members of council

• Safety Codes Officers

• Accredited Agencies and their employees and officers

• Administrators

Who is a Safety Codes Officer?

• Individual designated by Administrator

• Person who holds appropriate certificate of competency and meets the requirements of regulation

What Can a Safety Codes Officer Do?

• Enter premises without warrant

• Carry out an inspection

• Review designs and evaluate quality management systems and manufacturing, construction processes

• Photograph or otherwise record

• Ask for full disclosure in writing or orally

• Temporary close and disconnect

• Require tests or evaluations

• Apply to Court for enforcement

Who Else Can Require

Compliance?

• Energy Resources Conservation Board

(ERCB)

• Electrical Inspector

• Fire Department Inspector

• Insurance Company

What does Alberta Gas Code Regulation Require?

• CSA B149.1-10 Natural Gas and Propane Installation

Code

• CSA B149.2-10 Propane Storage And Handling Code

• CSA B149.5-10 Installation Code for Propane Fuel

Systems on Tanks on Highway Vehicles

• CSA B108-99 Natural Gas Fuelling Stations Installation

Code

• CSA B109.01 Natural Gas for Vehicles Installation Code

• Alberta Building Code 2006

Who is the CSA B149.3-10 Code For?

• CSA B149.3-10 Code For Field Approval of Fuel-

Related Components on Appliances And

Equipment

• CSA B149.3-10 is For Accredited Inspectors and

Safety Codes Officers

• CSA B149.3-10 Is Not a Design Guideline

• CSA B149.3-10 is a MINIMUM REQUIREMENT

• CSA B149.3-10 is not a LAW, it is just a guideline for Field Approvals

What is the CSA B149.1-10 For?

• CSA B149.1-10 is for Installers of:

• Appliances, equipment, components and accessories where gas is to be used for fuel purposes

• Piping and tubing systems from utility termination or propane tank

• Vehicle natural gas refueling appliances

• Stationary gas engines and turbines

What Else Does CSA B149.1-10 Reference?

• CSA B149.1-10 references 50 other standards

• Among those standards are:

• B51-09 Boiler, pressure vessel and pressure piping code

• B149.3-10 Code for Field Approvals

• C22.1 Canadian Electrical Code Part I

• National Building Code of Canada NRC 2005

What Does CSA B149.1-10 Include?

• Definitions

• Approval Requirements (B149.3)

• Responsibilities of the Installer (compliance, operator training, manufacturers instructions)

• Training and quality of labour

• Suitability of use

• Meter and Service Regulator

• Electrical Connections and Components

• Mobile Homes

• Hazardous Locations

What Does CSA B149.1-10 Include? (cont)

• Leak detection

• Appliance Clearances

• Appliance Accessibility

• Outdoor Installations

• Appliances in Garages

• Combined Heating Systems

• Automatic Fire Extinguishing systems

• High Altitude installations

• Odorization

What Does CSA B149.1-10 Include? (cont)

• Pressure Controls

• Piping and Tubing Systems (pressure drops, sizing, expansion)

• Venting of Pressure Controls (sizing)

• Installation of specific Appliances

• Flue Venting

• Combustion Air Supply

• Natural Gas Compressors and Cylinders

• Vehicle Refueling Appliances

Installer's Responsibilities

• Compliance With Above 27+ Installation Topics

• Use of ONLY Certified or Field Approved

Appliances

• Testing and Commissioning of the Installation

• Operator / Owner Training

• Documentation of Installation and User Manuals

• Rating Plate

• Appropriate Inspections, and Permits

What Is an Inspector Looking For?

• Appliance Proof of Certification (sticker).......... OR

• Compliance with (B149.3-10) :

• Pilot Gas Valve Train

• Main Gas Valve Train

• Burner

• Additional Requirements for Liquid Propane Trains

• Qualifications of the Installer (Mechanical, Electrical)

• Installation

• Unions and Flanges

• Pressure Test Points

• Pressure Ratings

• Bleed Vents Control Devices

What Is an Inspector Looking For? (cont)

• Observation of Main Burner Flame and Ignition Source

• Pneumatic Control Systems

• Ignition Systems

• Combustion Safety Controls

• Purge

• Low Fire Start

• Temperature, Pressure and Level Safety Limits

• Gas pressure Safety Limits

• Auxiliary Fans and Dampers

• Special Appliance Applications

• Appliance Location Hazards

What Is an Inspector Looking For? (cont)

• Accessibility

• Explosion Relief

• Temperature Controllers and Sensors

• Fuel /Air Ratio Controllers

• Gas / Air Mixers and Blowers

• Programmable Controllers (PLC’s)

• Electrical Power Supply

• Appliance Circuits (wiring diagram)

• Rating Plate

• Initial Startup Procedure

What Are The Objectives Of ENEFEN Field Approval?

• To Systematically Review Various Aspects of Design,

Assembly, Installation, Wiring, Testing, Commissioning,

Documentation, Operator Training

• To Confirm that the Final Installation Meets or Exceeds

Applicable Codes and Sound Combustion Engineering and

Controls Principles.

• To Review Potential Hazards and Methods of their

Avoidance / Mitigation

• To Confirm that the Installation can be Safely and Reliably

Operated and Maintained in its Process and Environment

What Does NFN Field Approval Consist Of?

• EVALUATION

• ENGINEERING & DESIGN

• DESIGN APPROVAL IN

PRINCIPLE

• FIELD INSPECTION

What Does NFN Field Approval Consist Of?

How Do We Do Field Approvals?

• Proprietary MySQL Database Of Field

Approval FAQs and FRAs

• Google Docs and Excel Interface

• Client Document Tracking System

• Automated and Repeatable Evaluation

Process

• Extensive Reporting Compliant with Code

Requirements

Data Base Content Groups

• Client and Owner Contact Data

• Client Project Data

• Process Data

• Location Data

• Appliance Data

• Main / Secondary / Pilot Fuel Data

• Instrument Gas Data

• Electrical Data

Data Base Content Groups (cont.)

• Heater Shell Data

• Fire Tube Data

• Stack Data

• Windbox Data

• Flame Cell Data

• Main Burner Data

• Pilot Burner Data

• Combustion Air Controls Data

Data Base Content Groups (cont.)

• Heater Permissives Data

• BMS / FSG Data

• Heater Control System

• Main Fuel Train

• Pilot Fuel Train

• Fuel Gas Venting

• Controls

• PLC Based BMS

Data Base Content Groups (cont.)

• Factory Acceptance Testing

• Marking and Alarms

• Installation Upstream Piping

• Installation Mechanical / Electrical

• Startup and Commissioning

• Combustion Readings

• Documentation

• Personnel Training

• Heater Code Compliance Data

How Do We Do Design and Engineering?

• Standard Design Codes

• Client and Application Templates

• Automatic Drawing Generation

• Automatic BOM Generation

• Library of Computerized Engineering

Subroutines

• Rating Plate Design Generation

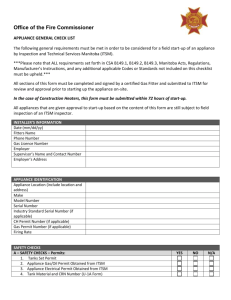

• Provincial Application Forms Generation

• P.Eng. Stamping for Alberta, BC and SK

Engineering Calculations?

• Thermal Heat Transfer

• Fuel Mixtures Properties

• Thermal Oxidation

• Fuel Train Pressure Drop

• PSV Sizing

• Vent Line Sizing

• Combustion Efficiency Calculation

• EfficiencyGram Calculation

How About Quality Control and Safety Compliance?

• Standards Of Operations Compliant with

ISO/IEC 17020

• Accreditation with Standards Council of Canada in Progress

• ENEFEN Field Approval Process Reviewed and

Accepted in writing by Alberta Municipal Affairs

• ISNetworld Registered

• Health and Safety Program in Place

• Approved Vendor for Various Oil Companies