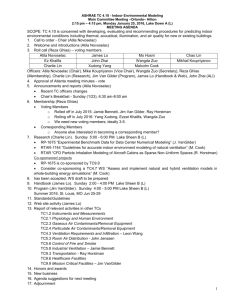

CE/ARE 397 Indoor Air Quality: Field Measurements

advertisement

The University of Texas at Austin Course: Spring 2012 Field Measurements: Building Energy and IEQ CE 397 Instructor: Dr. Novoselac, Atila ECJ 9.236 Office (512) 475-8175 e-mail: atila@mail.utexas.edu http://www.ce.utexas.edu/prof/Novoselac Office Hours: Tuesday and Thursday 11:00 – 12:00 p.m. Objectives • Introduce the course – – – – Motivation Schedule Evaluation Logistics • Describe other syllabus content • Address any of your concerns Introduce yourself • Name? • Grad/undergrad? • Department? • Your professional interest? Motivation for taking this course • Experimental part of your MS/PhD work • Building commissioning • Forensic engineering studies Course Objectives 1. Gain an appreciation for field and laboratory measurements relevant to: building energy performance and indoor environmental quality. 2. Learn about measurement techniques, instrumentation and complexities associated with their use (including accuracy and interference issues). 3. Obtain hands-on experience (in lab and field) with a number of basic instruments used in field investigations of buildings. 4. Analyze data from field and laboratory measurements and assess performance of buildings and their components. Course Topics 1. Course introduction and lab and field work safety 1 wk 2. Specifics of field and laboratory measurements 1 wk 3. Experimental error & quality control 2 wks 4. Velocity, flow, and pressure measurements 2 wks 5. Temperature, humidity, and heat and moisture flows 2 wks 6. Measurement of particulate matter 1 wk 7. Measurement of gaseous contaminants 1 wk 8. Electric power measurement 1 wk 9. Signal processing and data acquisition 1 wk 10. Sample collection and analysis 2 wks Total 14 wks 6 Textbook • There is no required textbook Instead • Course notes • Handouts • Hard or electronic copies of reading materials – Book sections – Journal papers – Instrument manuals Grading • • • • Midterm Test Classroom Participation Homework Assignments Final Project & Presentation 20% 10% 40% 30% 100% Test (20%) In-class exam Based on: • • • • readings lectures assignments lab and field measurements 9 Participation (10%) • Come to class and participate in measurements • Let me know about class(es) you will miss • Read assigned articles and contribute to discussion • Submit homework assignments in time • Participate as a team member • Handle equipment properly Homework Assignments (40%) • Calculation assignments • Measurement result processing • Correlation development • ….. 11 Final project (30%) • Independent study related to • your research topic or • a forensic engineering problem • Will include • • • • lab and field measurement results processing and analysis report writing presentation in class 12 Logistics • • • • • • • • Course website Class location and times PRC facilities Field trips/measurements Laboratory demonstrations Equipment Data analysis/record keeping Safety Website http://www.caee.utexas.edu/prof/Novoselac/classes/CE397/ • • • • Class notes Electronic handouts Assignments Grades 14 Class Location • This classroom • 50% of class time • Pickle Research Center labs and UTest house • 30% of class time • Field events • 20% of class time 33 15 PRC fasciitis • 5 Laboratories in building: PRC 133 • UTest house 133 16 Field measurement In the second part of the course • • • • • A campus building Facade thermal lab at UT School of Architecture City of Austin fire department facilities Pecan Street Project test house Other residential and commercial buildings • You are welcome to suggest a location 17 Schedule I need your availability for classes in PRC Filed trips will be scheduled in advance - 10 to 15 days in advance 34 18 Lab and UTest house demonstrations • Primarily me • Other faculty • BEE graduate students 19 Equipment • Equipment for field assignments should be organized at least a day before the assignment • All students are responsible for checking equipment in and out and returning it to lab • All equipment should be treated gently and any issues brought to my attention 36 20 Data analysis/record keeping • Students are responsible for handling all the lab and filed work data • You will need: • Lab/field note books • Flash drives for electronic data transfer • Installed some of the equipment software on your computer 21 Safety • Clothing • • • • Clothes that you don’t care about Nothing flowing No exposed skin except haands Close-toed shoes • UT EH&S (Laboratory) Safety Training (by the end of the next week) • http://www.utexas.edu/safety/ehs/lab/ • http://www.utexas.edu/safety/ehs/train/oh101.html • http://www.utexas.edu/safety/ehs/train/oh201.html Other issues • Course history • Course work load • Visiting lecturer • Your questions ? 23 Class Topics for today • Introduction to lab and field work, examples • Terminology Lab Measurement • Strictly design experiments • Focus on maintaining one group of parameter in a controlled environment to measure other • Motivation: • • • • • Mimic real environment for measuring certain phenomena Testing of product or technology Model development Validation ….. 25 Field Measurements • Often the only way to document the real world • Often conducted in conjunction with laboratory measurements • Many phenomena can not be meaningfully modeled or reproduced in the laboratory Example of Lab Work: Convection Correlation Development Heat transfer at floor in a room with displacement ventilation Q=A·h·ΔT h=f( air velocity, temperature difference , geometry ) V or ACH Tsurf-Tair or Tsurf-Tsupply 27 Room dimensions Convection Correlation Development Experimental Design h=f(Tsurf-Tair_local) h=f(ACH) Air velocity Tair q [W/m2] Flow rate [ACH] Measured permeates: - Heat flux - Surface temperature - Air temperature - Supply air temperature - Flow rate - Air velocity 28 Convection Correlation Development Instrumentation: Test room: - Strict energy and mass balance - Steady state condition Velocity sensors Thermistors Air Instrumentation: • Heat flux (power meter) • Temperatures (thermistors) • Flow (pressure based flow station) • Velocity (hot wire) Data acquisition Floor 29 Convection Correlation Development Sensitivity analysis results: Effect of temperature Q=A·h_temp_based·(Tsurf-Tair_local) Effect of flow rate Q=A·h_flow_based·(Tsurf-Tsupply_air) Convection correlation expressed as a function of volume flow rate 30 is stronger than correlation expressed as a function of temperature Convection Correlation Development Results In our cases we had turbulent flow h ~ velocity0.8 ~ ACH0.8 Function fitting: least square method 31 Example of Field Work: Energy Implications of Filters • Does using a better filter increase energy use? • Conventional wisdom: Yes • For smaller buildings: Maybe not • Flow, fan energy, system energy, SHR, AC capacity • All DECREASE 15 32 Experimental Design • Why can’t this study be done in a laboratory? • Monthly measurements in 17 buildings over the course of a year with different filters installed • Additional measurements in test house 16 33 Instrumentation • Power draw • Fan and compressor • Pressure drop • Filter and coil • Temp. and RH • Capacity • Fan flow • Duct leakage • Major issue? 34 Summary • Fieldwork is very messy • Confounding variables and outliers • Need large sample sizes • Expensive and time consuming 20 37 Terminology • What is the difference between accuracy and precision? • Note that these terms are often confused and conflated with other terms • Accuracy – “Capability of an instrument to indicate the true value of a measured quantity.” • Precision – “Repeatability of measurements of the same quantity under the same conditions; not a measure of absolute accuracy” • Precision not often reported Reference ASHRAE Guideline 2 Terminology • Example of accuracy and precision: High accuracy, low precision Low accuracy, High precision Good measurement result is both: accurate and precise Some Comments about Instrument Accuracy • Manufacturers are almost always optimistic • Make the difference between accuracy defined for full scale and reading Instrument 1: • Accuracy: ±1.5% of full scale • Repeatability: ±0.5% of full scale Instrument 2: • Accuracy: ±1.5 % of reading • Repeatability: ±0.5% (limited in certain range) • What is Repeatability? Some Comments about Instrument Accuracy • Accuracy is rarely constant over Range • Assume frequent calibration • Requires standard • Calibrate over range of interest • Don’t use complicated calibration curves • Anything other than linear requires justification • Consider arrangement with multiple sensors Other things that you should care about Sensitivity • Thermistors Sensitivity of the sensor is defined as the slope of the output characteristic curve Resistor Temperature range Which one is more sensitive? 42 Other things that you should care about • Response time Standard definition Can be defined for other % values Other things that you should care about • Response time • Hobo U12 internal temperature sensor • Response time in airflow of 1m/s (2.2mph) • 6 minutes, typical to 90% • Telaire 7001 CO2 sensor • <60 seconds to 90% of step change • How do you use these values? Other things that you should care about Hysteresis • Sensor should follow the changes of the mesured parameter regardless of which direction the change is made; hysteresis is the measure of this property How this affects the instrument accuracy? 45 Other things that you should care about Resolution • the smallest detectable incremental change of input parameter that can be detected in the output signal • Hobo U12 internal relative humidity sensor • 0.03% RH • Telaire 7001 CO2 sensor • ±1 ppm • How do you use these values? • Note that resolution can be limited by data logger Other things that you should care about • Range and detection limit • How do you use these values? • Note that you are often trading off range and resolution and/or accuracy • Example: • Measuring CO2 with Telaire 7001 CO2 sensor Other things that you should care about Example: In our test house we use CO2 as tracer gas We use Telaire 7001 CO2 sensor for concentration measurement What is the range accuracy and detection limit? http://www.microdaq.com/telaire/index.php 48 (Some) Real World Concerns • • • • • • • • First and operating cost Ease of use Safety Durability Flexibility Reliability Power requirements Environmental requirements/conditions