PPT - Penn State University

advertisement

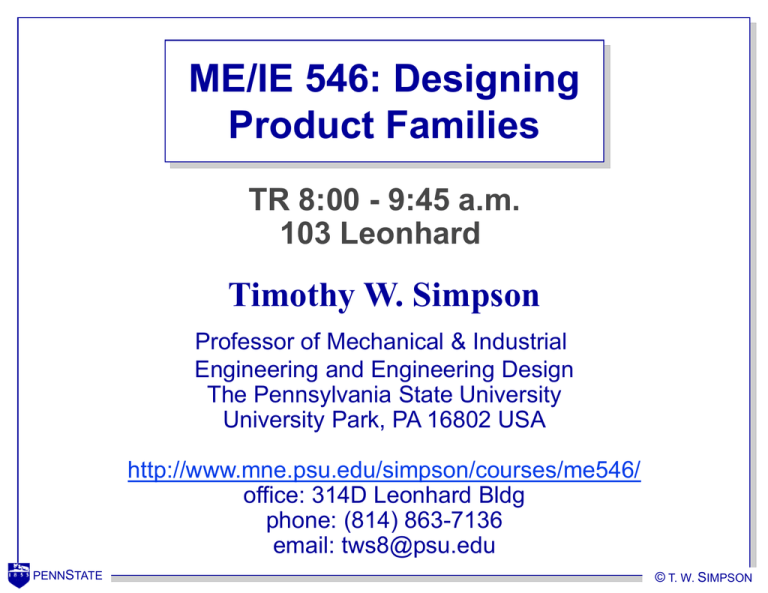

ME/IE 546: Designing Product Families TR 8:00 - 9:45 a.m. 103 Leonhard Timothy W. Simpson Professor of Mechanical & Industrial Engineering and Engineering Design The Pennsylvania State University University Park, PA 16802 USA http://www.mne.psu.edu/simpson/courses/me546/ office: 314D Leonhard Bldg phone: (814) 863-7136 email: tws8@psu.edu PENNSTATE © T. W. SIMPSON Ever looked inside a Kodak single-use camera? PENNSTATE © T. W. SIMPSON Ever noticed any similarity in Black & Decker’s Versapack® tools? PENNSTATE © T. W. SIMPSON How much commonality exists between products in the product family? How does that compare with what their competitors are doing? Today’s highly competitive and global marketplace is reshaping the way many companies do business as rapid innovation and mass customization offer a new form of competitive advantage. In response, companies like Sony, Black & Decker,and Kodak have successfully implemented strategies to design and develop families of products based on common product platforms to satisfy a wide variety of customer requirements. How can a company design and develop an effective platform-based product family? PENNSTATE © T. W. SIMPSON Syllabus (Tentative) • Weeks 1-2: Manufacturing Systems and Customer Demand Craft Production and the American System of Manufacturing Mass Production and Mass Customization • Weeks 3-4: Product Families and Product Platforms Definitions and Approaches to Product Family Design Examples of Successful Product Families • Weeks 5-11: Architecting Families of Products Product Architecture Modular Design Commonality PENNSTATE © T. W. SIMPSON Syllabus (cont.) • Weeks 5-11: Architecting Families of Products (cont.) Design for Variety Robust Design Scalable Product Platforms Product Family Optimization • Weeks 12-14: Manufacturing Considerations during Product Family Design Design for Manufacturing and Assembly Design for Mass Customization Supply Chain Management and Product Differentiation Postponement • Week 15: Wrap-up and Final Project Presentations PENNSTATE © T. W. SIMPSON Why Product Families? “Since many companies design new products one at a time, the focus on individual customers and products often results in a failure to embrace commonality, compatibility, standardization, or modularization among different products or product lines.” - Meyers and Lehnerd, 1997 • The end result: a “mushrooming” or diversification of products and components with proliferating variety and costs • To remain competitive, companies are utilizing product families and product platforms to: increase product variety shorten product lead-times reduce cost PENNSTATE © T. W. SIMPSON Sony Walkman® Platform Strategy • In 1980s, Sony dominated portable stereo market with three basic platforms: WM2, WMDD and WM20 Incremental changes accounted for only 20-30 of the 250+ models introduced in the U.S. Remaining 85% of Sony's models produced from minor rearrangements of existing features and cosmetic redesigns of the external case Ref: (Sanderson and Uzumeri, 1997) PENNSTATE © T. W. SIMPSON Source: Volkswagen A-Platform Development Car Division Audi A3 (3+ 5-door) Audi TT coupe Audi TT roadster VW Golf IV (3+5 door, station wagon, convertible, and Minivan) VW Bora VW Beetle Skoda Octavia (Bora sedan, coupe, convertible, and station wagon) (New Beetle, New Beetle convertible) (Octavia sedan, and station wagon) • VW plans for 19 vehicles based on A-platform • VW estimates development and investment cost savings of $1.5 billion/yr using platforms PENNSTATE Seat Toledo Successor (Toledo, coupe, station wagon, and convertible) © T. W. SIMPSON Definition of Key Terms • What is a product family and a product platform? • Product family: a group of related products that share common features, components, and subsystems; and satisfy a variety of markets • Product platform: the set of features, components or subsystems that remain constant from product to product, within a given product family • Variant or derivative: products derived from the product platform through: – addition, removal, or substitution of one or more modules ( module-based product family) – scaling or “stretching” the platform in one or more dimensions ( scale-based product family) PENNSTATE © T. W. SIMPSON Product Family Design Top-down Approach (Proactive): a company strategically manages and develops a family of products based on Black & a product platform and its moduleDecker and/or scale-based derivatives Work by: K. Otto, K. Ulrich, K. Wood, K. Ishii, M. Tseng Bottom-up Approach (Reactive): a company redesigns/consolidates a group of distinct products by standardizing components to improve economies of scale and reduce inventory Work by: D. Rosen, S. Kota, K. Ishii, Z. Siddique Sony Lutron PENNSTATE © T. W. SIMPSON Tools and Methods for Product Family Design • Maps Product family maps Market segmentation grid • Metrics Commonality indices Platform efficiency and effectiveness • Methods Modular design Scalable design Resolving product family tradeoffs Determining product platform extent PENNSTATE © T. W. SIMPSON Identify Platform Leveraging Strategy • Market segmentation grid can be used to identify and map platform leveraging strategies (Meyer, 1997) High Cost High Performance Mid-Range What Market Niches Will Your Product Serve? Low Cost Low Performance Segment A Segment B Segment C Derivative Products Product Platform PENNSTATE © T. W. SIMPSON Example Leveraging Strategies: B&D Cordless Industry (Heavy) Use MidRange Home (Light) Use Saws PENNSTATE Drills & Drivers Lighting © T. W. SIMPSON Commonality Metrics • Much of focus in product family design is to improve commonality and standardization within the family • Why is commonality good? Better economies of scale (and scope) Decrease lead times (and risk) in new product development Reduce set-up and retooling time Fewer components in inventory Fewer parts need to be tested and qualified Improves overall product quality Commonality is a useful metric for product families: % Commonality = %Cx = PENNSTATE 100 * common X common X + unique X © T. W. SIMPSON Module-Based Product Families • Modular design is best known approach for effective product family design Design a product platform that can be up easily modified by adding, subtracting, and/or upgrading of modules • Designing a module-based product family involves defining its product architecture (Ulrich, 1995): the arrangement of functional elements the mapping of functional elements to physical components the specification of the interfaces among physical components • Common modules in family form product platform • Standardized interfaces facilitate addition, substitution, and removal of modules PENNSTATE © T. W. SIMPSON Modularity in the Automotive Industry Different Modules in an Automobile Dashboard Module PENNSTATE Source: • Shimokawa, K., Jurgens, U., and Fujimoto, T. (Eds), 1997, Transforming Automobile Assembly, Springer, New York. © T. W. SIMPSON Scale-based Product Families • Develop a product platform that can be “scaled” or “stretched” in one or more dimensions to satisfy a variety of market niches • Boeing 737 is divided into 3 platforms: Initial-model (100 and 200) Classic (300, 400, and 500) Next generation (600, 700, 800, and 900 models) • The Boeing 777 has also been designed knowing that it will be “stretched” PENNSTATE © T. W. SIMPSON Resolving Tradeoffs in Product Family Design Performance • Product family design involves the design of multiple products to maximize commonality within the family with minimal sacrifice in individual product performance Individually Optimized Designs Poor Designs Best Designs Designs Based on Common Platform How do we ensure that this tradeoff is “optimal” for us and our company? Management & Marketing $ Design Engineering Manufacturing & Production Degree of Commonality PENNSTATE © T. W. SIMPSON Closing Remarks • Product family design is a complex and difficult task: embodies all of the challenges of product design while adding the complexity of coordinating the design of multiple products to improve commonality with minimal performance sacrifice • The key to a successful product family is the product platform around which it is derived: multiple platform leveraging strategies module-based product family scale-based product family • A variety of tools and methods are being developed to facilitate product family and product platform design; however, there is no silver bullet PENNSTATE © T. W. SIMPSON Course Objectives Throughout the semester, the following question will be addressed by the class: How can product realization teams provide increased product variety at less cost for a highly competitive, global marketplace? Within the context of this question, students at the end of the semester will be able to: define what is meant by a product family and a product platform, understand the difficulties of realizing mass customized goods and product families, become familiar with and implement state-of-the-art methods and tools for product family and product platform design, and demonstrate the application of this knowledge in the context of a group project. PENNSTATE © T. W. SIMPSON Course Textbook • Editors: Timothy W. Simpson, Zahed Siddique, & Jianxin (Roger) Jiao • Year of Publication: 2005 • Publisher: Springer (New York) • Focus: Methods for designing product platforms and product families PENNSTATE © T. W. SIMPSON Target Audience • Our target audience includes: 1. Researchers and Ph.D. students in Mechanical Engineering, Industrial Engineering, Computer-Integrated Manufacturing, and related fields in Engineering Management 2. Practitioners involved in Design, Planning and Production in the manufacturing industry • We wanted to provide an overview of the more mature research that has occurred, emphasizing methods for: developing platform architectures identifying platform leveraging strategies positioning products within a family planning the extent of the product family optimizing families of products based on platforms including platform case studies from industry PENNSTATE © T. W. SIMPSON Contributing Authors • Over 30 authors contributed 22 chapters • Authors span academia as well as industry: Penn State, MIT, Georgia Tech, Michigan, BYU, Bucknell, UIUC, University of Oklahoma Osaka University, Nanyang Technological University, University of Twente, Chalmers University of Technology ABB, PRTM, Robust Systems & Strategy, Infotiv, Hofer & Partner, KPMG Advisory Services • National and international contributors from: United States, Netherlands, Switzerland, Sweden, Finland, Germany, Malta, Japan, Singapore PENNSTATE © T. W. SIMPSON Chapter 1: Introduction & Overview Chapter 1 Product Variety and Customization Definitions of Platforms and Product Families General Approaches to Platform Design Module-Based Product Families and Examples Scale-Based Product Families and Examples Discuss Organization of the Book • Authors: – Timothy W. Simpson, Penn State University – Zahed Siddique, Oklahoma University – Jianxin (Roger) Jiao, Nanyang Technological University (Singapore) PENNSTATE © T. W. SIMPSON Pictorial Overview (Chapter 1) Part IV: Applications Part IV: Applications Part Part PartI:I: PartII: II: Front End Issues Optimization Based Front-End Issues Optimization-BasedMethods Methods Part Part III: III: Back End Issues Back-End Issues Product Process Product Customer Portfolio Functional Platform Physical Platform Process Domain Domain Domain Domain Customer Needs (CNs) Functional Requirements (FRs) Design Parameters (DPs) Process Variables (PVs) Customer Satisfaction Functionality Technical Feasibility Manufacturability and Cost Product Definition PENNSTATE Product Design Process Design © T. W. SIMPSON Part I: Front-End Issues in Platforming Chapters 2-7 2: Effective Platform Planning in the Front-End – Daniel Bowman, PRTM 3: Platform-Driven Development of Product Families – Johannes I. M. Halman, University of Twente (Netherlands), Adrian P. Hofer, Hofer & Partner (Switzerland), and Wim van Vuuren, KPMG Advisory Services (Malta) 4: Platform Concept Selection – Katja Hölttä-Otto, MIT (UMass-Dartmouth) with Kevin Otto, Robust Systems and Strategy 5: Platform Leveraging Strategies and Market Segmentation – Tucker Marion and Timothy W. Simpson, Penn State University 6: Product Family Positioning – Jianxin Jiao and Yiyang Zhang, Nanyang Technological University (Singapore) 7: Commonality Indices for Product Families – PENNSTATE Henri J. Thevenot and Timothy W. Simpson, Penn State University © T. W. SIMPSON Part II: Optimization-Based Approaches Chapters 8-12 8: Methods for Optimizing Platforms and Families – Timothy W. Simpson, Penn State University 9: Commonality Decisions in Platform Design – Michael Kokkolaras, Ryan Fellini, and Panos Y. Papalambros, University of Michigan 10: Product Variety Optimization – Kikuo Fujita, Osaka University (Japan) 11: Analytical Target Cascading in Product Family Design – Ryan Fellini, Michael Kokkolaras, and Panos Y. Papalambros, University of Michigan, with Harrison H. Kim from UIUC 12: Determining Product Platform Extent – PENNSTATE Olivier de Weck, MIT © T. W. SIMPSON Part III: Back-End Issues in Platforming Chapters 13-18 13: Roadmap for Product Architecture Costing – Sebastian K. Fixson, University of Michigan 14: Activity-Based Costing for Product Families – Jaeil Park and Timothy W. Simpson, Penn State University 15: Product Platform Redesign using Platforms – Zahed Siddique, University of Oklahoma 16: Process Platforms and Product Configuration – Jianxin (Roger) Jiao, Lianfeng Zhang, and Shaligram Pokharel, Nanyang Technological University (Singapore) 17: Measuring Shape Commonality – Zahed Siddique, University of Oklahoma 18: Process Parameter Platform Design – PENNSTATE Christopher B. Williams, Janet K. Allen, David W. Rosen, and Farrokh Mistree, Georgia Tech © T. W. SIMPSON Part IV: Applications Chapters 19-22 19: Ice Scraper Platforms at Innovation Factory – Steven B. Shooter, Bucknell University Ice dozer Mini dozer variants 20: Engineering Platforms and Families at ABB – Srinivas Nidamarthi and Harshavardhan Karandikar, ABB (Germany) 21: Product Design Generator at Honeywell – Gregory M. Roach and Jordan J. Cox, BYU 22: Platform Management Practice at Cetetherm – PENNSTATE Tobias Holmqvist and Magnus Persson, Chalmers University of Technology (Sweden) with Karin Uller from Infotiv © T. W. SIMPSON Grading • Individual Homework 20% • Group Project and Homework Assignments 50% • Learning Diary and Final Learning Essay 20% • In-Class Discussion and Participation 10% PENNSTATE © T. W. SIMPSON Product Family Dissection and Benchmarking • Several of the homework assignments involve dissecting a family of products to benchmark it using tools and methods discussed in class • Of 4 models examined: %CIcomponents = 79-96% %CIconnections = 82-94% PENNSTATE © T. W. SIMPSON Other Product Families We Have Dissected Single-Use Cameras Versapak Tools Portable Stereo Corded Drills PENNSTATE © T. W. SIMPSON Delayed Product Differentiation • Bosch manufactures braking systems for GM, Toyota, etc. What types of partial commonization are most essential for manufacturing complexity reduction? How can our manufacturing strategy best enable savings from product commonization? • Study a key component in the braking system, the Master Cylinder: http://howstuffworks.lycoszone.com/master-brake1.htm PENNSTATE © T. W. SIMPSON Incorporate Versapack® into Design Repository • Researchers at the University of Missouri-Rolla, in collaboration with NIST, have developed a Design Repository for storing product information: http://function.basiceng.umr.edu/Repository_Data • Current repository only supports individual products. • Objectives: Analyze the products in the Versapack® tool set Enter the product descriptions in the Design Repository Investigate methods for representing product families more efficiently within the Design Repository PENNSTATE © T. W. SIMPSON An Emphasis on Learning •As you watch this movie, ask yourself: Is this a funny or sad commentary about our educational practices? PENNSTATE © T. W. SIMPSON Learning How to Learn • I challenge you to take charge of your own learning • I will present several learning “aids” and “tools” to facilitate this process Learning “Box” Competent Observe-Reflect-Articulate (ORA) Diagram: Incompetent Observe Know You Know Know You Don’t Know Conscious Reflect Don’t Know You Know Don’t Know You Don’t Know Unconscious Articulate PENNSTATE © T. W. SIMPSON Kolb’s Learning Cycle • Kolb’s model of experiential learning provides a framework for understanding learning styles Accomodator (Asks What If?) Concrete Experience (Feeling) Quadrant 4 Quadrant 1 Active Experimentation (Doing) Reflective Observation (Watching) Quadrant 3 Coverger (Asks How?) PENNSTATE Divergers (Asks Why?) Quadrant 2 Abstract Conceptualization (Thinking) Assimilator (Asks What?) © T. W. SIMPSON Learning Styles • Index of Learning Styles theory was developed by Dr. Richard Felder at North Carolina State University • Four dichotomies based upon one’s learning propensity Visual vs. Verbal Sensing vs. Intuitive Active vs. Reflective Sequential vs. Global • To determine your learning style preference, go to: http://www.engr.ncsu.edu/learningstyles/ilsweb.html PENNSTATE © T. W. SIMPSON Learning Diary and Final Learning Essay • I ask that you maintain a “Learning Diary” over the course of the semester I want you to reflect on what you have observed in class and articulate how that relates to learning about how you learn This should be typed, about ½-page long, and submitted bi-weekly to the drop box on Angel by 5pm on Thurs 1/15, 1/29, 2/12, 2/26, 3/19, 4/2, 4/16 (5 out of 7 are required) • At the end of the semester, you will submit a 2-3pg final learning essay (due 5pm, Fri, 5/1) that summarizes: what you have learned about your own learning over the course of the semester how you will take charge of your own learning in the future PENNSTATE © T. W. SIMPSON Assignment 0: Individual Goals and Objectives • Why are you here? • List five things you would like to achieve in this course. • Analyze and make corrections. Change their order? Refine your thoughts? The first thing you write down may not be the most important -- upon analysis. • What do you really want to achieve in this course? • What is your biggest fear about taking this course? PENNSTATE © T. W. SIMPSON